Wire Based Laser Metal Deposition Lmd W Fraunhofer Ipt

Wire Based Laser Metal Deposition Lmd W Fraunhofer Ipt In wire based laser metal deposition (lmd w), a wire is melted locally with the laser beam and applied to the component surface in specific layers. in this way, the desired components or structures can be built up layer by layer. lmd w was originally designed for wear protection. however, it is now increasingly being used as a process for. A special feature of wire based laser deposition welding is its quasi 100 percent material efficiency, since the supplied material is completely melted and applied to the component surface in layers. with appropriate cam support and multi axis process control, additional functional elements in hybrid design can be built on existing components.

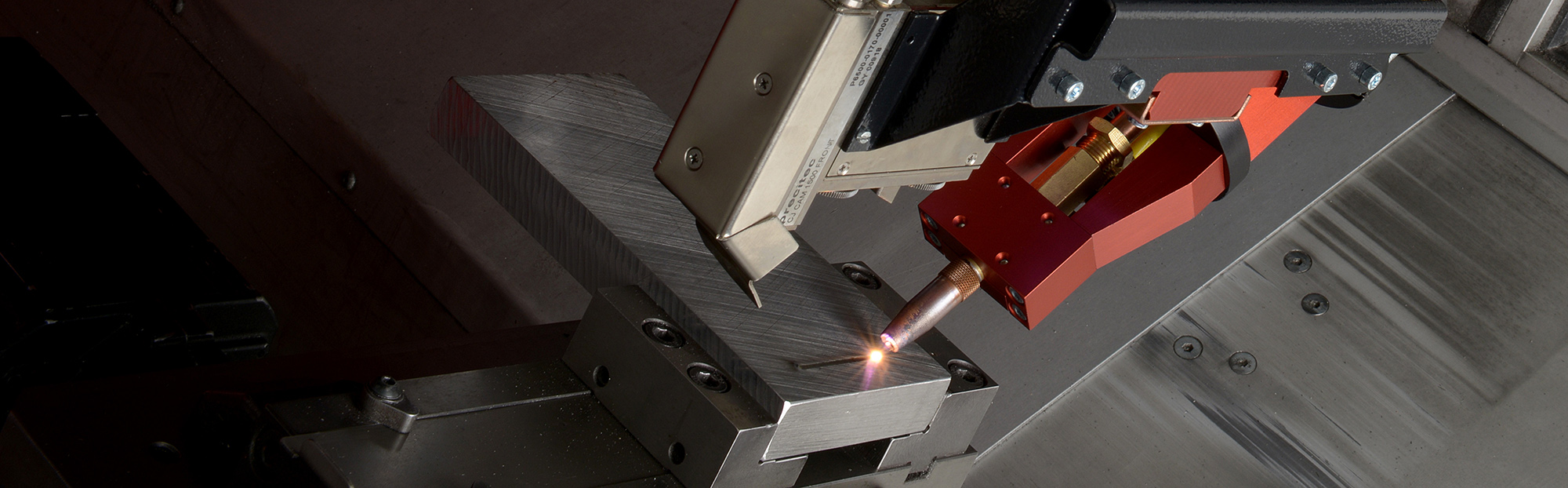

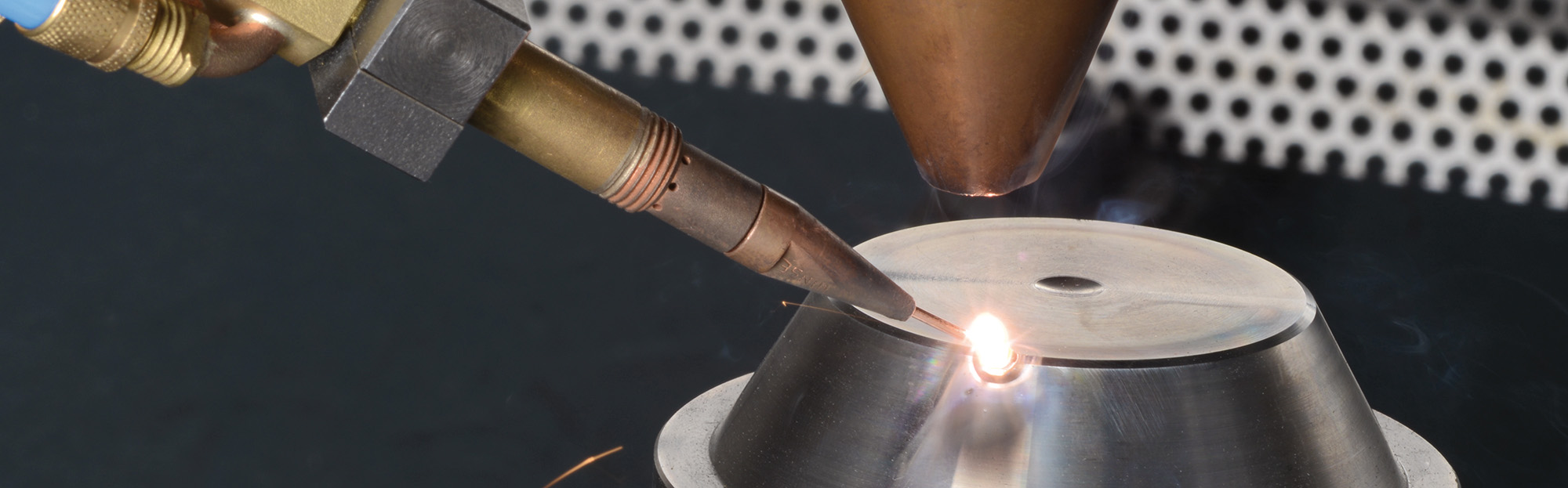

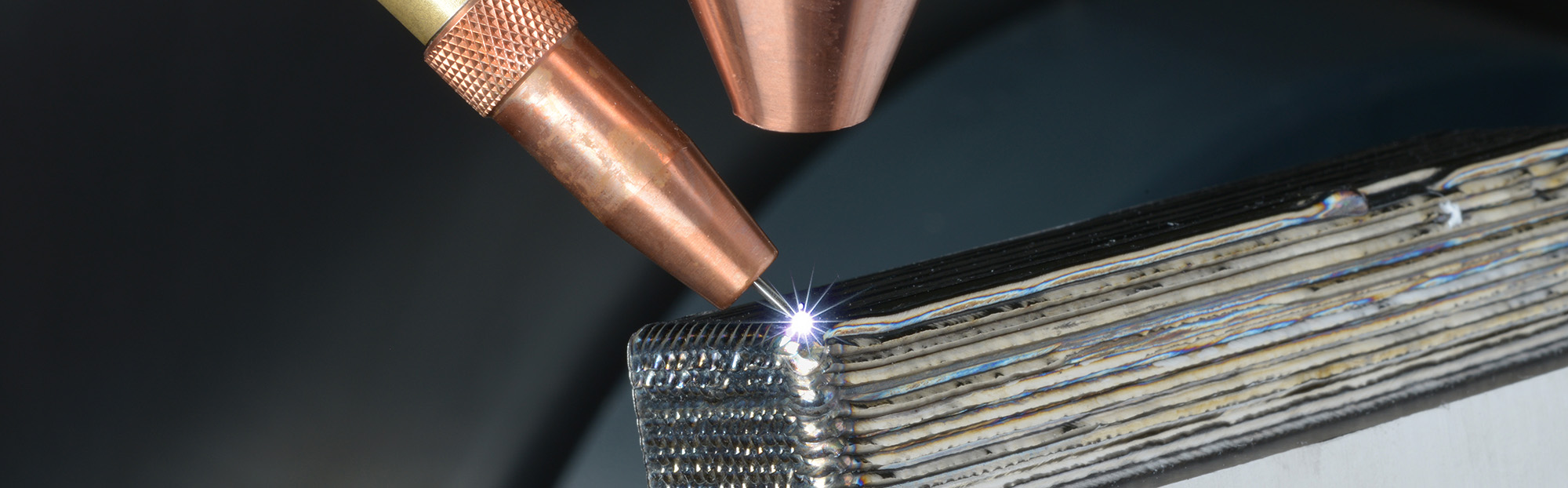

Wire Based Laser Metal Deposition Lmd W Fraunhofer Ipt Position alignment between wire and laser spot is crucial. alignment has to be performed for lateral wire feed in two axis. incomplete melting or droplet formation can occur, if misaligned. z position of the wire head influences the alignment. thermal impact on the material low due to beam to wire diameter (1.5 : 1). Inconel 718 component build by lmd w process motivation large scale parts are in great demand for additive manufacturing (am). for these requirements, the fraunhofer ipt has developed a wire based laser metal deposition (lmd w) process since several years, as an alternative pro cess to a powder based process with many advantages :. For these requirements, the fraunhofer institute for production technology ipt has developed since years a wire based laser metal deposition (lmd w) process. main advantages associated with the lmd w process are the high material efficiency in deposition, the prevention of machine room from contamination, the manufacturing of parts with high. The protective coatings are produced by a combination of wire and powder based laser metal deposition (lmd w p). in the "lmd hybrid" research project, the fraunhofer ipt and its partners are qualifying an lmd w p process for the production of graded tic reinforced coatings. for this purpose, the group is first fundamentally determining.

Wire Based Laser Metal Deposition Lmd W Fraunhofer Ipt For these requirements, the fraunhofer institute for production technology ipt has developed since years a wire based laser metal deposition (lmd w) process. main advantages associated with the lmd w process are the high material efficiency in deposition, the prevention of machine room from contamination, the manufacturing of parts with high. The protective coatings are produced by a combination of wire and powder based laser metal deposition (lmd w p). in the "lmd hybrid" research project, the fraunhofer ipt and its partners are qualifying an lmd w p process for the production of graded tic reinforced coatings. for this purpose, the group is first fundamentally determining. Fraunhofer institute for production technology ipt our p a r tn e r wire based laser metal deposition (lmd w) of titanium grade 5 martin schulz m.sc. phone: 49 241 8904 560, [email protected] m oti v a ti on titanium is an astonishing lightweight material, however:. Together with its industrial and research partners, the fraunhofer institute for production technology ipt has, therefore, integrated the imaging inspection method optical coherence tomography (oct) into a coaxial process for wire based laser metal deposition, or lmd w.

Schematic Of The Laser Metal Deposition Lmd System Download Fraunhofer institute for production technology ipt our p a r tn e r wire based laser metal deposition (lmd w) of titanium grade 5 martin schulz m.sc. phone: 49 241 8904 560, [email protected] m oti v a ti on titanium is an astonishing lightweight material, however:. Together with its industrial and research partners, the fraunhofer institute for production technology ipt has, therefore, integrated the imaging inspection method optical coherence tomography (oct) into a coaxial process for wire based laser metal deposition, or lmd w.

Comments are closed.