Why You Should Never Solder Wires On Your Car

Why You Should Never Solder Wires On Your Car Youtube After years of being an automotive technician i have plenty of horror stories of bad automotive wiring fixes. in this video i aim to help anyone that finds t. With your copper wire strands fully prepped you will next “tin” the wire ends. tinning is the process of applying heat to the bare wire end(s) via your soldering iron and feeding a small amount of solder into the wire strands to coat the wires evenly. this helps prevent fraying and improves conductivity.

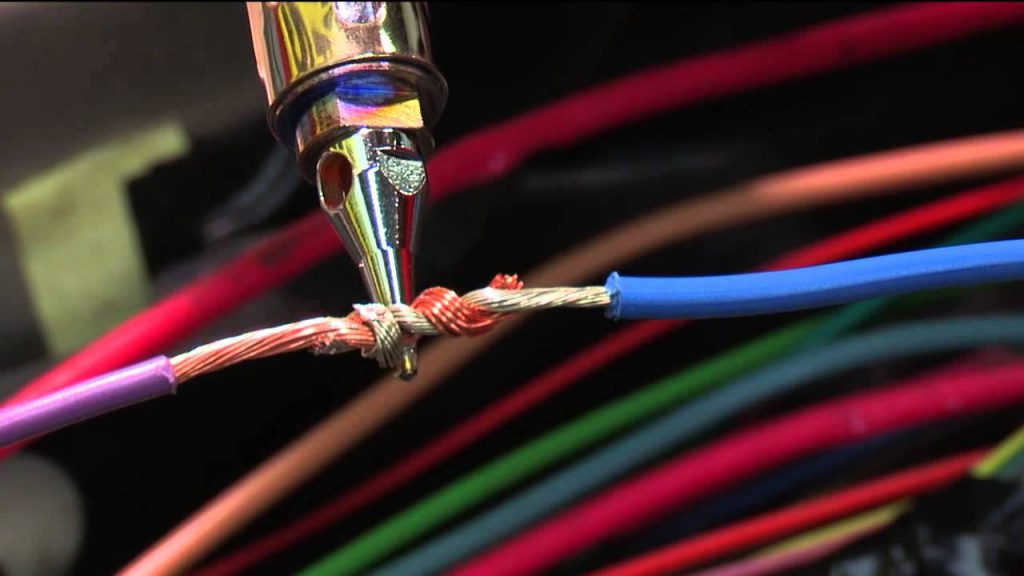

Should You Crimp Or Solder Wires In A Vehicle Anthonyj350 Youtube With almost 30 years in the business, tens of thousands of wiring harnesses sold, and millions of feet of wiring, they would be the people to know. “the best connection is a crimp with plastic cover, or a non insulated terminal covered with a high quality heat shrink to protect the connection. this will provide a connection that doesn’t. Solder on automotive wire harness: soldering is a traditional way of terminating wires. you use a molten metal, solder, to form a reliable and strong connection between wires, cables, or any other electrical components. the metal solder can be anything of silver, brass, or tin. heat the metal to a temperature above 600 degrees fahrenheit with a. But don't worry, even if you find yourself in a situation where you must solder or despite the risk it is something you wish to do anyway, andre outlines of the things you can do to help mitigate that risk of failure by running through a few common places in a motorsports loom where it is your only option. solder sleeves (not the horrible knock. If you want to get it done right use a soldering iron and some flux with it. to make it easier get someone to hold the stereo wire with the flux against it, and press the soldering iron onto it. make sure you get a coating over most the copper for a strong connection. 1. share.

How To Solder Automotive Wires Tips And Tricks But don't worry, even if you find yourself in a situation where you must solder or despite the risk it is something you wish to do anyway, andre outlines of the things you can do to help mitigate that risk of failure by running through a few common places in a motorsports loom where it is your only option. solder sleeves (not the horrible knock. If you want to get it done right use a soldering iron and some flux with it. to make it easier get someone to hold the stereo wire with the flux against it, and press the soldering iron onto it. make sure you get a coating over most the copper for a strong connection. 1. share. Number 1: the manufacturer has a pretty good idea of the current capacity of the fuse panel in your car. shoving wiring under a fuse in the panel is not a safe way to power up your new accessory, as you could exceed the safe current capability of the circuit. number 2: most people install these incorrectly!. I always solder and heat shrink. wire nuts are good for a quick connection on solid wire. but if you look at the inner portion of the nut, you'll see a threaded area. this thread is meant to cut into the solid wire for a better connection, cuts stranded wire into seperate pieces.

Comments are closed.