Why Understanding Gd T Helps To Create Better Parts Gd T Basics

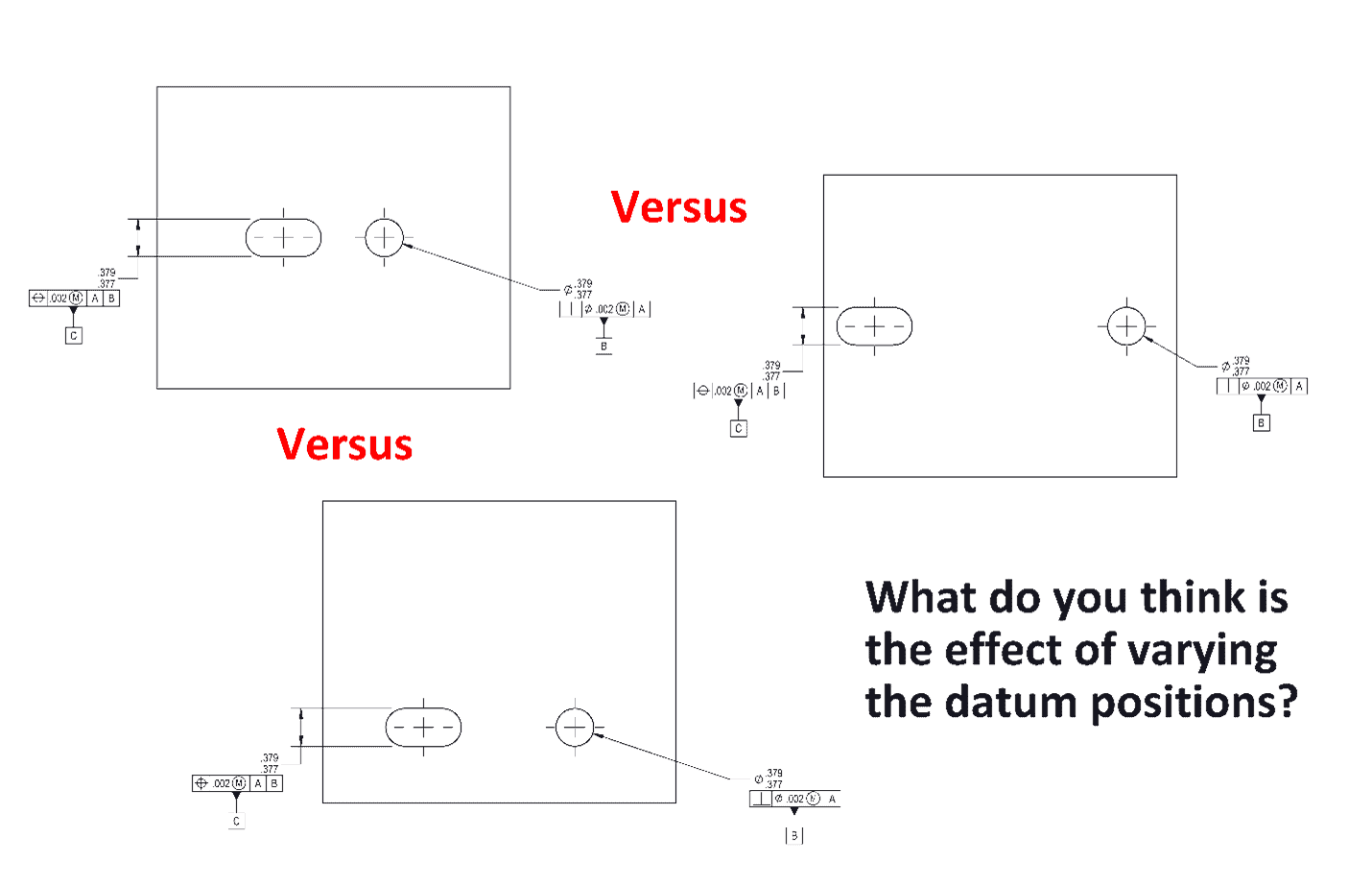

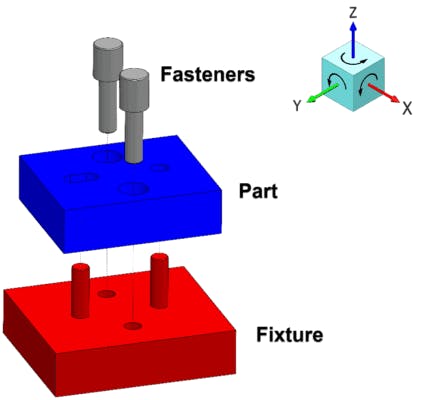

Why Understanding Gd T Helps To Create Better Parts Gd T Basics Understanding the ideas behind gd&t can literally help you design functionally better parts! but how so, specifically? model 1. on model 1 above, the blue piece represents a simple mechanical part that you, as an engineer, might want to create. it has two counterbored holes designed with clearance for fasteners. By crystal bemis on april 27, 2022. we get a lot of questions from students asking why they would want to use geometric dimensioning and tolerancing (gd&t) over coordinate dimensions. some believe that using gd&t will result in tighter tolerances and increase a part’s cost. others believe that coordinate dimensioning is just easier to.

Why Understanding Gd T Helps To Create Better Parts Gd T Basics 1. clear measurement requirements. when it comes to the inspection of a part, gd&t has a great advantage over coordinate tolerancing. with coordinate tolerancing, dimensions of the part are given, but the drawing does not indicate how the part is to be set up for measurement. this can result in very different measurement values for the same. Gd&t stands for geometric dimensioning and tolerancing and it refers to the system of designating and communicating tolerances for specifications beyond the basic dimensions of the part. these functional specifications include form and size on a technical drawing. used properly, this system can quite effectively reduce the costs of. For complicated assemblies this is daunting process, but gd&t gives you a language and a rule set to do so, but it is not without cost. the table below highlights the pros and cons of gd&t at a high level. gd&t is a language and rule set. gd&t is standardized by the asme y14.5 2018 dimensioning and tolerancing standard. this standard lays out. Geometric dimensioning and tolerancing (gd&t) is a system used to define and communicate engineering tolerances. it uses symbols and mathematical definitions to describe the form, profile, orientation, location, and runout of a part. gd&t is an essential part of modern engineering as it precisely explains how parts will fit and function together.

Why Understanding Gd T Helps To Create Better Parts Gd T Basics For complicated assemblies this is daunting process, but gd&t gives you a language and a rule set to do so, but it is not without cost. the table below highlights the pros and cons of gd&t at a high level. gd&t is a language and rule set. gd&t is standardized by the asme y14.5 2018 dimensioning and tolerancing standard. this standard lays out. Geometric dimensioning and tolerancing (gd&t) is a system used to define and communicate engineering tolerances. it uses symbols and mathematical definitions to describe the form, profile, orientation, location, and runout of a part. gd&t is an essential part of modern engineering as it precisely explains how parts will fit and function together. Gd&t defines a part’s features and its allowable deviation from its true or ideal position. the general goal of gd&t is to highlight the most important features of a part and demonstrate how those features connect to the bigger picture. gd&t covers the geometric dimensions of a component as well as its tolerance values. Course description. gd&t fundamentals teaches a simple framework that allows students to not only understand how geometric dimensioning and tolerancing is used, but also why gd&t improves the manufacturing process. the course is focused on practical knowledge and uses real world examples from our clients as instructional tools.

Comments are closed.