Why Most Widely Used Pumps Are Centrifugal Pump In Industries Part 6

Why Most Widely Used Pumps Are Centrifugal Pump In Industries Part 6 In this video we are going to discuss about the ; centrifugal pumps applicationwhy most widely used pumps are centrifugal pump?centrifugal pump interview que. One of the main advantages of a centrifugal pump is its simple design, which results in low maintenance and operating costs. it also allows for high flow rates and can handle varying viscosities without significant loss in performance. also, centrifugal pumps are self priming, meaning they can operate without the need for manual priming.

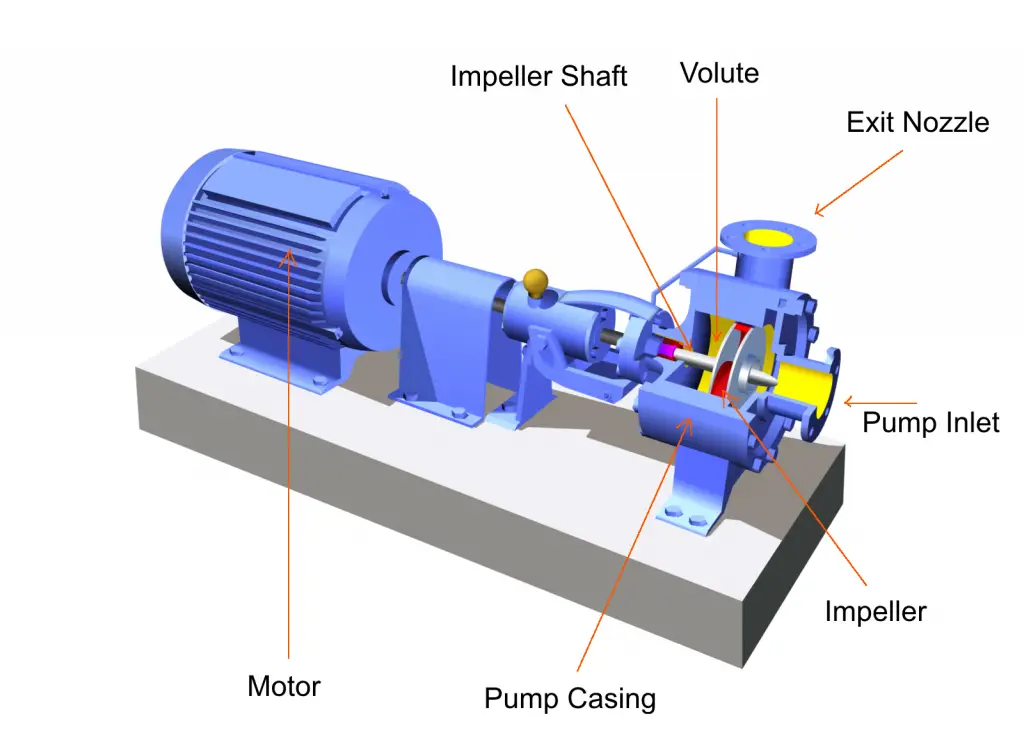

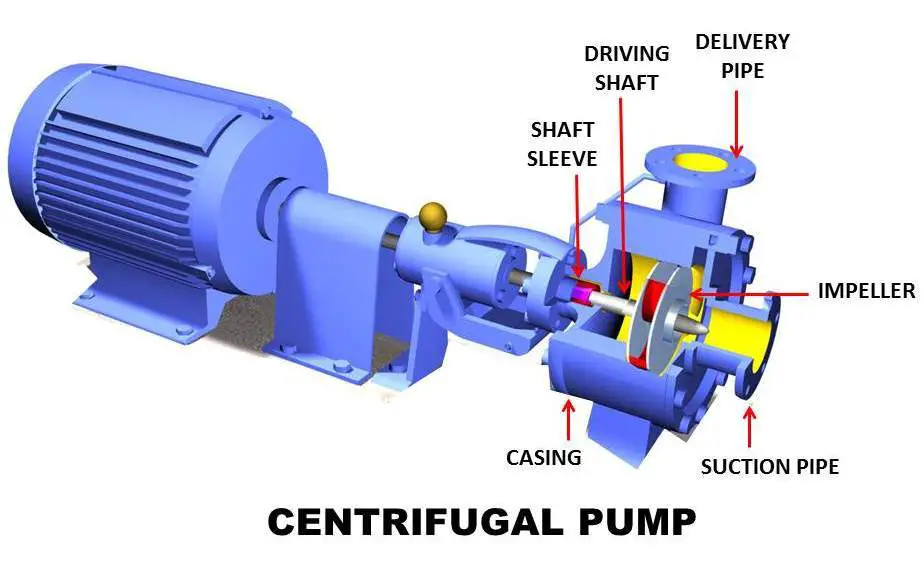

What Is A Centrifugal Pump The Engineer S Perspective The centrifugal pump is one of the most widely used fluid handling devices in the refining and petrochemical industry. every plant has a multitude of these types of pumps operating. a brief description of the various designs found in operating plants follows. refer to table 4.3.1 for the application limits of dynamic pumps. The mechanism of a centrifugal pump is relatively simple. it consists of three main components: an impeller, a casing, and a shaft. the impeller is a rotating component that contains blades or vanes that move the fluid. the casing is a stationary component that surrounds the impeller and guides the fluid to the discharge point. Simply put, a centrifugal pump is a mechanical device designed to move fluid by means of the transfer of rotational energy from one or more driven rotors, known as impellers. fluid enters along the pump’s centerline and is then directed towards the pump outlet by the impeller’s vane, gaining velocity and pressure during the process [^1^]. Here are some of the major applications of these pumps. pumping water and other low to medium viscous fluids. domestic and industrial water supply. sewage and slurries pumping. fire protection sprinkler systems. food and beverage production. crude oil and slurry pumping in oil & gas industries. refrigeration and air conditioning.

Centrifugal Pump Components Types And Applications Engineering Simply put, a centrifugal pump is a mechanical device designed to move fluid by means of the transfer of rotational energy from one or more driven rotors, known as impellers. fluid enters along the pump’s centerline and is then directed towards the pump outlet by the impeller’s vane, gaining velocity and pressure during the process [^1^]. Here are some of the major applications of these pumps. pumping water and other low to medium viscous fluids. domestic and industrial water supply. sewage and slurries pumping. fire protection sprinkler systems. food and beverage production. crude oil and slurry pumping in oil & gas industries. refrigeration and air conditioning. Here’s how simscale helps the mechanical industry in centrifugal pump simulation: 1. robust meshing. simscale’s multi purpose cfd solver provides a robust meshing strategy, generating an automated body fitted mesh which is crucial for capturing the fluid flow accurately within and around the pump geometry. Design of centrifugal pumps. the three primary components of a centrifugal pump are: the impeller, pump casing, and the shaft. 1. impeller. the impeller is the key component that imparts the fluid with kinetic energy. impellers can be open, semi open, or enclosed. the type of impeller used is determined by the characteristics of the liquid to.

Comments are closed.