What Is The Hdg Process American Galvanizers Association

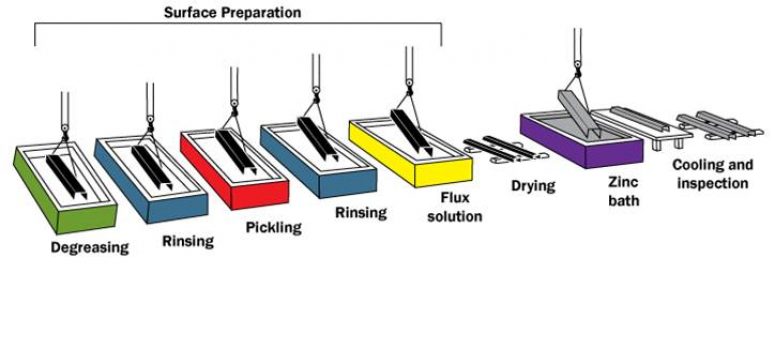

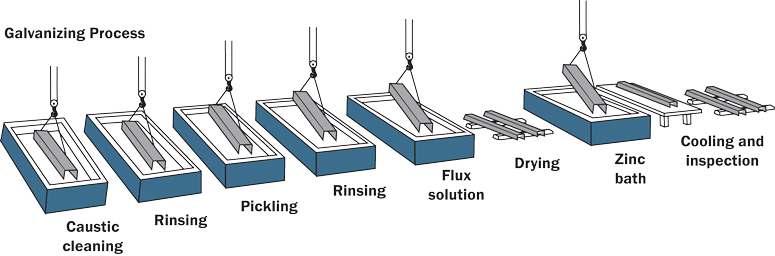

Hot Dip Galvanizing Hdg Process American Galvanizers Association The hot dip galvanizing (hdg) process consists of three basic steps: surface preparation galvanizing inspection surface preparation surface preparation is a critical step in the application of any coating. the galvanizing process has its own built in means of quality control because zinc will not…. The definition of hot dip galvanizing (hdg), as referenced on this site, is the process of dipping fabricated steel into a kettle or vat containing molten zinc. the process is inherently simple which provides a distinct advantage over other corrosion protection methods. while the steel is in the kettle, the iron in the steel metallurgically.

Hdg Process American Galvanizers Association Hot dip galvanizing (hdg) for more than 150 years, hot dip galvanizing after fabrication has been specified to combat steel corrosion in the harshest environments throughout various markets. however, new technologies and creative chemistries evolve the specification and use of hot dip galvanized steel constantly as new markets emerge. once. Venting and drainage details. as hot dip galvanizing involves the immersion of steel in a series of process tanks, it is critical to ensure the free flow of pretreatment solutions, air, and zinc so a smooth and uniform coating is achieved. improper venting and drainage details can result in poor appearance, bare spots, excessive build up of. Hot dip galvanizing purposes may be removed after galvaniz ing. for smaller parts (less than 18” in length, e.g. fasteners) baskets are used to handle the material and lifting points are not required. in some instances, the galvanizer may have specially designed racks to accommodate the galvanizing of certain products. Hot dip galvanization. hot dip galvanization is a form of galvanization. it is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °c (842 °f). when exposed to the atmosphere, the pure zinc (zn) reacts with oxygen (o 2.

What Is The Hdg Process American Galvanizers Association Hot dip galvanizing purposes may be removed after galvaniz ing. for smaller parts (less than 18” in length, e.g. fasteners) baskets are used to handle the material and lifting points are not required. in some instances, the galvanizer may have specially designed racks to accommodate the galvanizing of certain products. Hot dip galvanization. hot dip galvanization is a form of galvanization. it is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °c (842 °f). when exposed to the atmosphere, the pure zinc (zn) reacts with oxygen (o 2. Is the size and shape of the fabrication. because hot dip galvanizing is a total immersion process, the design must take into consideration the capacity of the galvanizing kettle; therefore, it is wise to verify kettle constraints with your galvanizer early in the design process. almost any component can be galvanized. Galvanizing service in buffalo, ny. hot dip galvanizing, according to the american galvanizers association, is defined as the process of dipping fabricated steel into a kettle or vat containing molten zinc. this process has been used time and time again for rust proofing and other corrosion protect services.

Hdg Process American Galvanizer S Association Is the size and shape of the fabrication. because hot dip galvanizing is a total immersion process, the design must take into consideration the capacity of the galvanizing kettle; therefore, it is wise to verify kettle constraints with your galvanizer early in the design process. almost any component can be galvanized. Galvanizing service in buffalo, ny. hot dip galvanizing, according to the american galvanizers association, is defined as the process of dipping fabricated steel into a kettle or vat containing molten zinc. this process has been used time and time again for rust proofing and other corrosion protect services.

What Is The Hdg Process American Galvanizers Association

Galvanize It Seminar American Galvanizing Association American

Comments are closed.