What Is The Difference Between Selective Laser Sintering

Selective Laser Sintering Manufacturing Britannica Selective laser sintering falls under the powder bed fusion umbrella, and uses polymer powders with a laser to print. this is a very similar method to direct metal laser sintering, however this involves metal powders instead. some also note similarities between selective laser sintering and hp’s new and innovative multi jet fusion technology. We’ll explore the differences between two of these am processes: stereolithography (sla) and selective laser sintering (sls). first, there’s a difference between ultraviolet (uv) lamp cured.

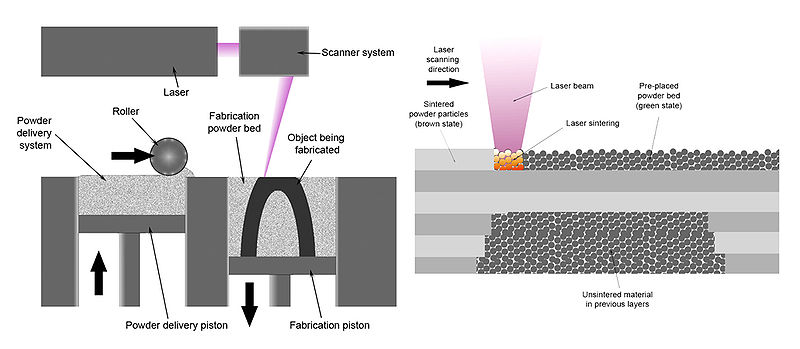

Guide To Selective Laser Sintering Sls 3d Printing Selective laser sintering (sls) an sls printer first spreads a thin layer of powder over the build platform. a co2 laser then scans each cross section, sintering the powder. the platform then descends by one layer and the process repeats until the build is complete. the entire bin must cool before you can remove the part from the powder. Sls (selective laser sintering) is a 3d printing technique that uses a laser to fuse together small particles of plastic, metal, glass, or ceramic powder into a solid object. sla (stereolithography) uses an ultraviolet (uv) laser to cure (harden) photosensitive resin into the desired shape. Selective laser sintering (sls) is a 3d printing process (additive manufacturing) that uses high powered lasers to sinter, or bind, finely powdered material together into a solid structure. in this process, a printer lays down an even layer of powder and then precisely sinters that layer, repeating the deposition and sintering process until the. Selective laser sintering (sls), in contrast to other additive manufacturing techniques like stereolithography (sla), fused deposition modeling (fdm), or fused filament fabrication (fff), does not require support structures because the powder works as a self supporting material. this makes it possible to create complex geometries.

Green Mechanic Comparison Between Selective Laser Melting Slm And Selective laser sintering (sls) is a 3d printing process (additive manufacturing) that uses high powered lasers to sinter, or bind, finely powdered material together into a solid structure. in this process, a printer lays down an even layer of powder and then precisely sinters that layer, repeating the deposition and sintering process until the. Selective laser sintering (sls), in contrast to other additive manufacturing techniques like stereolithography (sla), fused deposition modeling (fdm), or fused filament fabrication (fff), does not require support structures because the powder works as a self supporting material. this makes it possible to create complex geometries. Selective laser melting is a powder bed fusion 3d printing technology that is used to manufacture metal parts. like dmls, slm debuted in 1995. it was ultimately commercialized by a company called slm solutions. slm uses a laser to selectively melt the metal powder. the laser is high powered, so it very quickly liquifies any metal powder it. The complete guide to sls 3d printing. by carolyn schwaar. updated aug 2, 2024. selective laser sintering (sls) is the leading 3d printing technology for functional polymer parts. learn how it works and which 3d printers do it best.

What Is Selective Laser Sintering Live Science Selective laser melting is a powder bed fusion 3d printing technology that is used to manufacture metal parts. like dmls, slm debuted in 1995. it was ultimately commercialized by a company called slm solutions. slm uses a laser to selectively melt the metal powder. the laser is high powered, so it very quickly liquifies any metal powder it. The complete guide to sls 3d printing. by carolyn schwaar. updated aug 2, 2024. selective laser sintering (sls) is the leading 3d printing technology for functional polymer parts. learn how it works and which 3d printers do it best.

Green Mechanic Comparison Between 3d Printing 3dp And Selective

What S The Difference Between Stereolithography And Selective Laser

Comments are closed.