What Is The Difference Between Cnc Milling And Turning Pep Mfg Inc

What Is The Difference Between Cnc Milling And Turning Pep Mfg Inc The workpiece is held firmly in place by a chuck and may spin at different speeds depending on the operation being performed. while cnc milling works well for complex parts, cnc turning is better suited for creating cylindrical, axially symmetrical parts. components that may benefit from cnc turning include the following: conical shapes. shafts. 2 axis mori seiki frontier l ii. 2 axis doosan lynx 2100. 2 axis mori seiki nl1500. 4 axis mori seiki nl2500y 700 turning & milling center. 4 axis doosan lynx 2100 lyb turning & milling center. there are a variety of benefits to working with pep manufacturing. some of our capabilities include: reverse engineering.

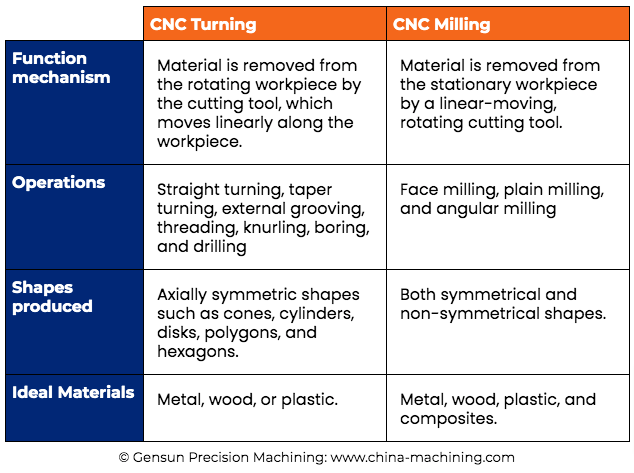

What Is The Difference Between Cnc Milling And Turning Pep Mfg Inc Cnc turning services from pep manufacturing. cnc turning produces a broad variety of high quality parts and products, but it’s important to find the right provider to ensure quality and reliability. at pep manufacturing, we can provide reliable cnc turning services using state of the art technology in conjunction with our skilled operators. Turning machines rotate a part, while milling machines rotate the cutting tool. a skilled machinist can use either machine or both, to create parts cut to exacting tolerances. peter jacobs is the senior director of marketing at cnc masters, a leading supplier of cnc mills, milling machines, and cnc lathes. Cnc milling offers greater geometric flexibility compared to turning. it can create a wide range of complex shapes, including pockets, slots, contours, and intricate 3d features. milling allows for the production of parts with diverse geometries, making it suitable for more complex and customized components. They are milling and turning. both are cnc machining methods but they are not the same. cnc refers to computer numerical control, meaning that cnc milling and cnc turning use computer systems to guide the cutting machinery. good cad cam software can easily translate a 3d model into readable code for cnc machines. this determines the use and.

Cnc Turning And Milling Do You Understand The Difference Cnc milling offers greater geometric flexibility compared to turning. it can create a wide range of complex shapes, including pockets, slots, contours, and intricate 3d features. milling allows for the production of parts with diverse geometries, making it suitable for more complex and customized components. They are milling and turning. both are cnc machining methods but they are not the same. cnc refers to computer numerical control, meaning that cnc milling and cnc turning use computer systems to guide the cutting machinery. good cad cam software can easily translate a 3d model into readable code for cnc machines. this determines the use and. Cnc milling necessitates securing the material in place while the cutting tools revolve around it. in contrast, cnc turning demands the tools to remain stationary while the material rotates at high speeds to craft the desired shape. further distinctions that underscore the contrast between cnc turning and milling include:. Imagine a drill moving towards a piece of wood. turning, however, uses a lathe machine. on a lathe, the material is what spins while a stationary tool advances into it. imagine a clay pot being made, spinning on a pottery wheel. the main difference between cnc milling and cnc turning is which piece spins: the cutting tool or the stock material.

Comments are closed.