What Is Lsaw And Ssaw Pipe Wilsonpipeline

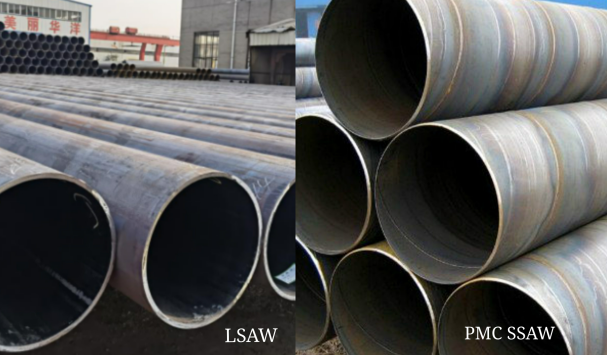

What Is Lsaw And Ssaw Pipe Wilsonpipeline Lsaw and ssaw are variants of saw (submerged arc welded) pipes. the difference between them is the way they are welded. in lsaw pipes, the welding is longitudinal, which means that steel (hot rolled coil plate) is rolled into a pipe and the seam is welded longitudinally. in the ssaw type, steel coils are welded spirally, like a helix, so that. Ssaw steel pipe is a coiled steel pipe made from strip coils as the raw material, which is often warm extruded and welded by an automatic double wire double sided submerged arc welding process. the strength of the ssaw steel pipe is generally higher than that of the lsaw steel pipe.

Ssaw Vs Lsaw Steel Pipe Wilsonpipeline At the same time, there are many types of forming methods for lsaw steel pipes: uo (uoe), rb (rbe), jco (jcoe), etc. the steel plate is first pressed into a u shape in the forming die, and then pressed into an o shape, and then internally and externally submerged arc welding is performed. after welding, it is usually called uoe welded pipe at. Ssaw and lsaw pipes employ a common manufacturing procedure called “jcoe and uoe forming process”. the difference is ssaw pipes are welded in the helix or spiral position while lsaw pipes are welded in the longitudinal direction. ssaw pipe takes form by rolling and welding a steel strip in a way that the pivotal direction is oblique to the. Economy. considering cost effectiveness, erw and ssaw are generally less expensive, while smls and lsaw offer higher performance in certain demanding applications. reliability and durability. choose a reputable manufacturer to ensure the quality and reliability of your pipe. Ssaw pipe: typically used for larger diameter pipes ranging from 20 inches to 100 inches (508 mm to 2540 mm). it can handle thick wall thicknesses up to 25.4 mm. lsaw pipe: used for a broader.

Difference Between Spiral Steel Pipe And Lsaw Steel Pipe Wilsonpipeline Economy. considering cost effectiveness, erw and ssaw are generally less expensive, while smls and lsaw offer higher performance in certain demanding applications. reliability and durability. choose a reputable manufacturer to ensure the quality and reliability of your pipe. Ssaw pipe: typically used for larger diameter pipes ranging from 20 inches to 100 inches (508 mm to 2540 mm). it can handle thick wall thicknesses up to 25.4 mm. lsaw pipe: used for a broader. C. applications of ssaw pipes. ssaw pipes find their applications in various industries, including oil and gas, water transport, and structural construction. their versatility makes them a popular choice for projects with diverse requirements. lsaw pipes a. definition and explanation of lsaw pipes. lsaw pipes are crafted using a longitudinal. Ssaw steel pipe. smls, erw, lsaw, and ssaw are some of the common production methods used in the production of steel pipes. here are some of the main differences between them: understanding the differences between these steel pipes can help ensure that the material best suited to the project's needs is selected to optimize performance, cost.

What Is A Ssaw Steel Pipe Wilson Pipeline Manufacturing Co Ltd C. applications of ssaw pipes. ssaw pipes find their applications in various industries, including oil and gas, water transport, and structural construction. their versatility makes them a popular choice for projects with diverse requirements. lsaw pipes a. definition and explanation of lsaw pipes. lsaw pipes are crafted using a longitudinal. Ssaw steel pipe. smls, erw, lsaw, and ssaw are some of the common production methods used in the production of steel pipes. here are some of the main differences between them: understanding the differences between these steel pipes can help ensure that the material best suited to the project's needs is selected to optimize performance, cost.

Comments are closed.