What Is Flange Classification Of Flanges And Flange Faces And Its Applications

Flange Faces Explained Flat Raised Etc Savree The flange face has an area beyond the normal (male) flange face. the other flange or mating flange has a matching recess (female) machined into the face. the female face is 3 16″ deep and the male face is 1 4″ high, both with a smooth finish. the outer diameter of the female face is used to locate and hold the gasket. Many different flange standards are found worldwide to allow easy functionality and interchangeability. common standards include asa asme (usa), pn din (european), bs10 (british australian), and jis ks (japanese korean). flanges come in many different shapes and sizes and are used in a wide range of industries around the world.

13 Different Types Of Flanges And Their Applications Pdf Raised face – rf flange. raised face flange has a small portion around the bore raised from the face. the gasket seat on this raised face. the height of the raised face depends on the flange pressure temperature rating, known as a flange class. for 150# & 300# height of the raised face is 1 16”, and above 300#, it is 1 4”. What is a flange? types of flanges and their applications what is a flange? a flange is a connecting element commonly used to join pipes or pipe components together or to secure equipment to a surface. flanges can typically be round or square and are used in various industrial applications. a flange has two main components: a flange face and. Existing flange spec is so you can assure that the bolt pattern will mate. flange face and gasket surface options ansi b16.5 flanges are most commonly supplied with a raised face, however are available with flat faces. awwa flanges are mostly commonly provided as flat face, and may be supplied with raised face by special request. There are two primary manufacturing methods for flanges: forging: flanges are formed by heating and shaping the material under pressure. forged flanges are stronger and more durable, making them ideal for high pressure applications. casting: molten metal is poured into a mold to form the flange.

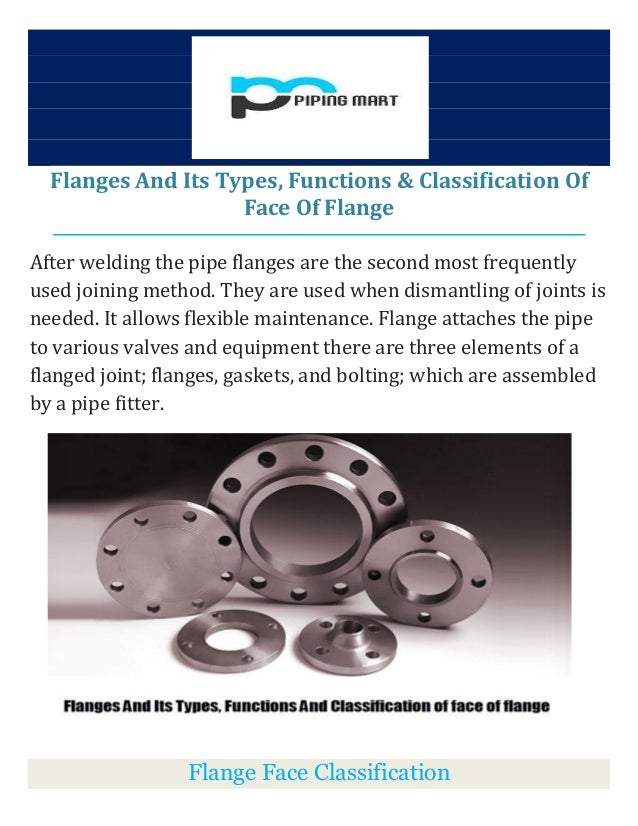

Flanges And Its Types Classification Of Flange Face Existing flange spec is so you can assure that the bolt pattern will mate. flange face and gasket surface options ansi b16.5 flanges are most commonly supplied with a raised face, however are available with flat faces. awwa flanges are mostly commonly provided as flat face, and may be supplied with raised face by special request. There are two primary manufacturing methods for flanges: forging: flanges are formed by heating and shaping the material under pressure. forged flanges are stronger and more durable, making them ideal for high pressure applications. casting: molten metal is poured into a mold to form the flange. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. a cover plate can be connected to create a "blind flange". [1] flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. A flange is a connecting element commonly used to join pipes or pipe components together or to secure equipment to a surface. flanges can typically be round or square and are used in various industrial applications. a flange has two main components: a flange face and flange connection holes. the flange face is mounted onto the surface of the.

Comments are closed.