Weld Symbols Blueprints Introduction To Welding Symbols Welding

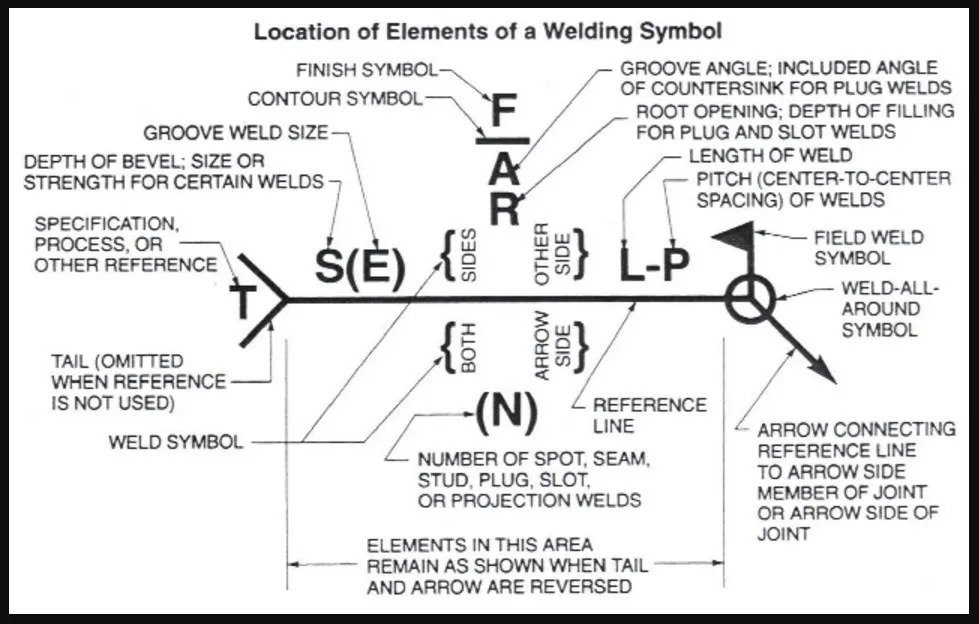

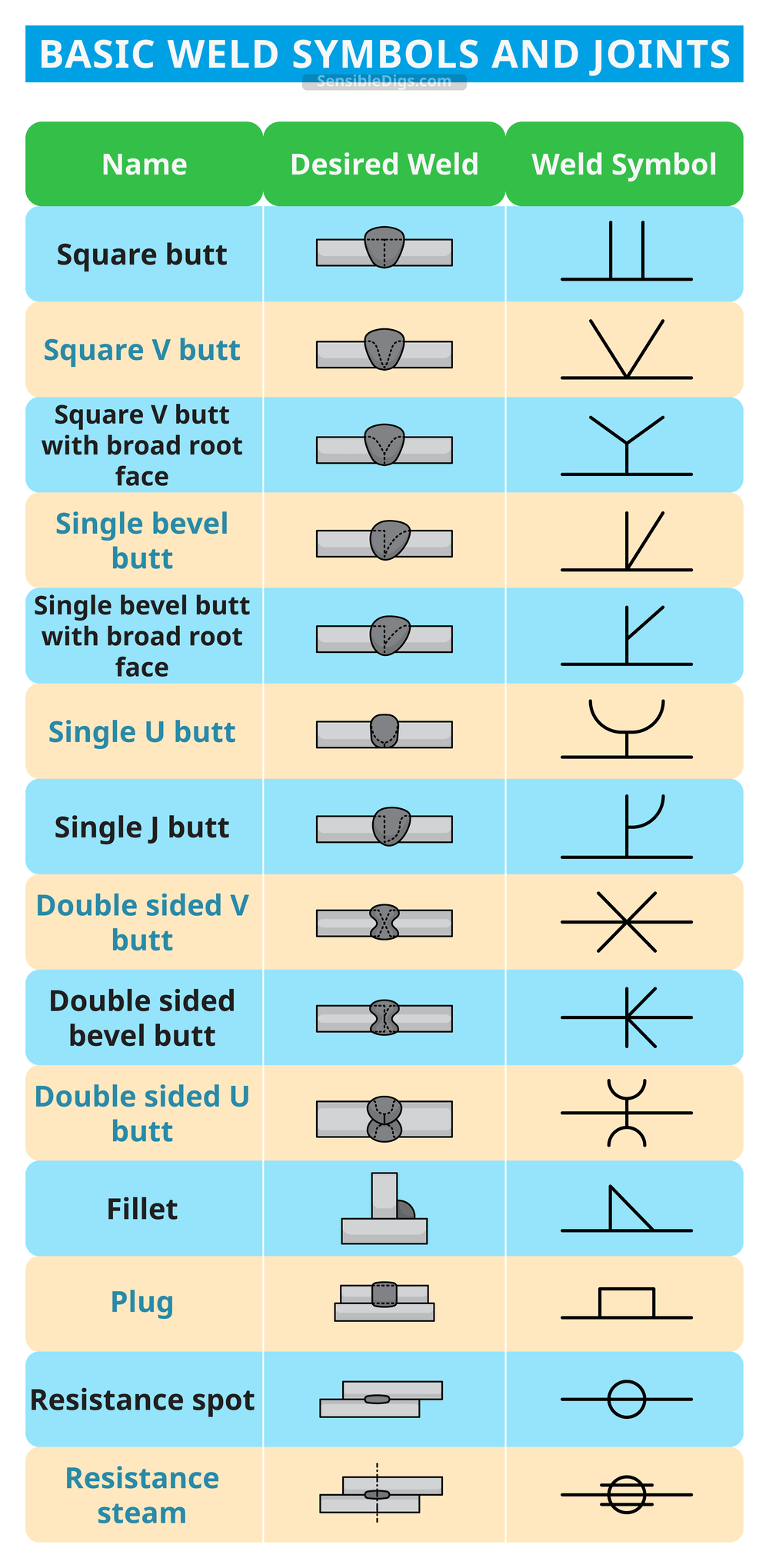

Welding Blueprint Symbols Signs Explained W Chart Welding symbols are used to indicate desired welding & brazing details on the fabrication drawings. the welding symbol is a graphical representation that is used to give the design requirements to the shop in a concise manner. for e.g. a symbol can be used to specify the weld type, groove design, welding process, face & root contour, weld. Weld symbols are a key part of welding documentation, and understanding how to read weld symbols is critical for welders. there are three main elements to a weld symbol: tail. the reference line is a horizontal line that is used to align the other elements of the symbol. the arrow is used to point to the location of the weld, and the tail.

Weld Symbols Blueprints Introduction To Welding Symbols Welding For instance. (example 1) indication: weld height is 3, staggered welding, weld seam length is 50, interval is 30, site welding is required. example 2: statement: spot weld diameter is 5, the number of spot welds is 10, and the interval is 30. example 3: indication: the weld height is 3, with full welding around. Spacer – this symbol indicates the type and the dimension of the spacer that is inserted between the welded pieces. weld all around – it signals that the weld is to be made over the entire circumference. flag symbol – field weld made on site. contour – these symbols designate the final weld end product contour. Blueprints, so named for the obsolete process of impregnating paper with a light sensitive chemical, ammonium ferric acid (turning the paper blue), to reproduce plans and drawings, are the most effective means of communicating fabrication requirements from the engineer to the fabricator (blueprint, 2023). welding symbols are a standardized. The 9 steps below represent a very basic introduction to welding symbols. this is just barely skimming the surface of weld symbols training. if you have a questions please let us know by replying to the post. welding symbols basics. every weld symbol must consist of an arrow and a reference line. the arrow may point up or down.

Welding Symbols Blueprints, so named for the obsolete process of impregnating paper with a light sensitive chemical, ammonium ferric acid (turning the paper blue), to reproduce plans and drawings, are the most effective means of communicating fabrication requirements from the engineer to the fabricator (blueprint, 2023). welding symbols are a standardized. The 9 steps below represent a very basic introduction to welding symbols. this is just barely skimming the surface of weld symbols training. if you have a questions please let us know by replying to the post. welding symbols basics. every weld symbol must consist of an arrow and a reference line. the arrow may point up or down. This information is often communicated via the blueprint. welding can require a lot of specific information, for example: the type and size of the weld, the required weld groove preparation, the extent and location of the weld. welding symbols provide a space saving method for conveying all this, and more, information. A welding symbol is what you see above and contains the arrow, reference line, and tail. you can remove the tail if there’s no information needed in it. you place a weld symbol on the reference line of a welding symbol to indicate what type of weld you require. 1. reference line.

Understanding The Basic Welding Symbols This information is often communicated via the blueprint. welding can require a lot of specific information, for example: the type and size of the weld, the required weld groove preparation, the extent and location of the weld. welding symbols provide a space saving method for conveying all this, and more, information. A welding symbol is what you see above and contains the arrow, reference line, and tail. you can remove the tail if there’s no information needed in it. you place a weld symbol on the reference line of a welding symbol to indicate what type of weld you require. 1. reference line.

Comments are closed.