We Tested Hss Sls And Mjf Which Is The Best Youtube

We Tested Hss Sls And Mjf Which Is The Best Youtube Yes, the concept of a "best 3d printing method" is broken. it's really about the most appropriate tool for the job. so, let's see what's available in the ind. High speed sintering (hss), multi jet fusion (mjf), and selective laser sintering (sls) industrial 3d printing methods all produce, at first glance, similar looking results. however, as the 3d.

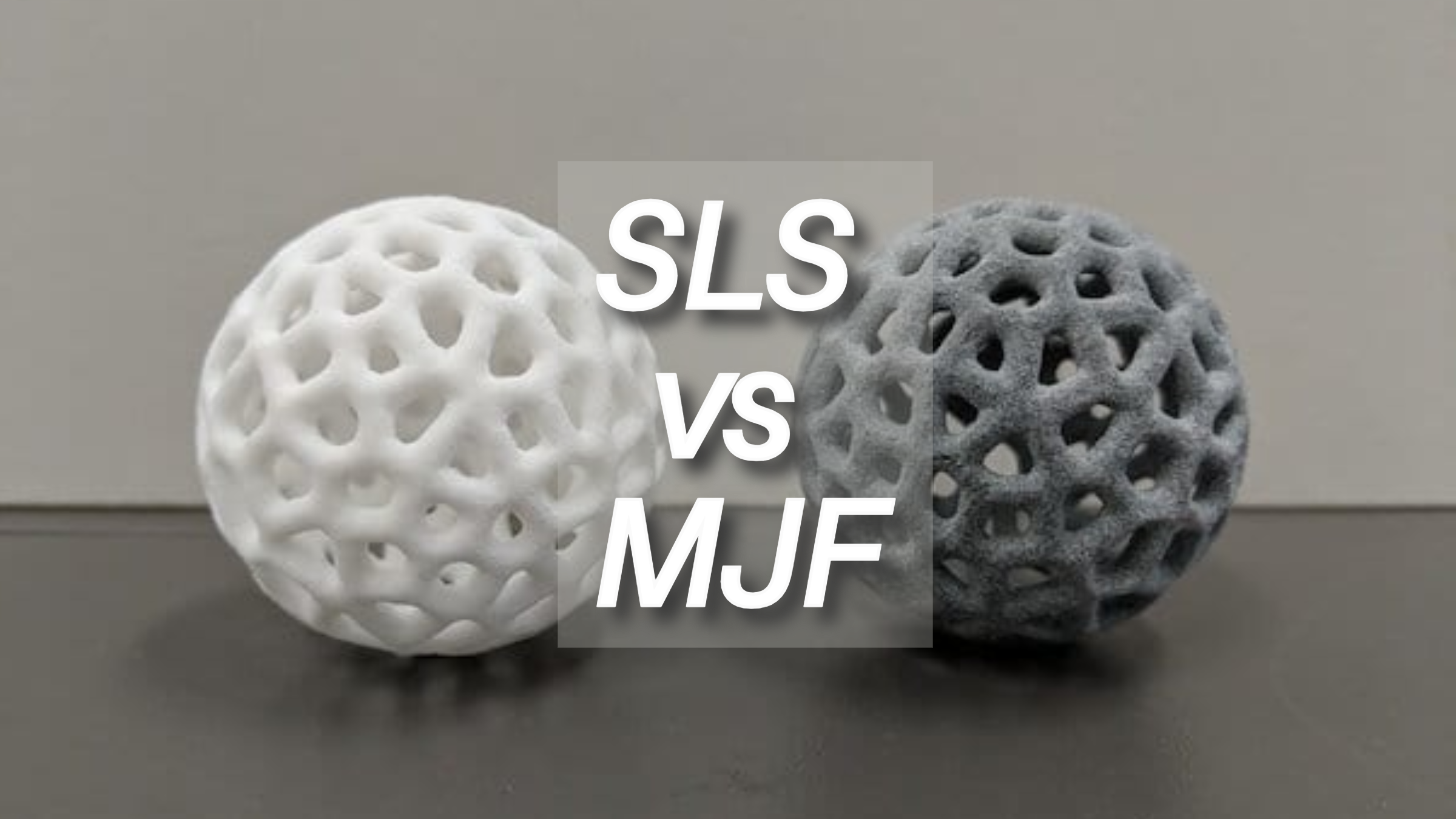

Hss Sls Mjf大比併 哪種3d列印技術是最好 Learn what the main differences between mjf and sls 3d printing are. Comparison of printing processes. the primary difference between mjf and sls lies in their heat sources: mjf uses infrared heat to fuse areas defined by its detailing and fusing agents, while sls relies on a laser to sinter the powder. this distinction leads to variations in surface finish, detail, and mechanical properties. Sls 3d printing was the first powder bed 3d printing technology, and has been a popular choice for engineers and manufacturers for decades. invented in 1982 by a group of researchers at the university of texas at austin, sls refers to technology in which a high powered laser sinters a thin layer of powder from above to form a solid cross section of the desired geometry. Resolution comparison of hss and mjf. image via voxeljet. looking at some of the key tech specs, mjf systems have a maximum build volume of 380 x 294 x 380mm, while the voxeljet vx1000 hss.

Hss Sls Mjf大比併 哪種3d列印技術是最好 Sls 3d printing was the first powder bed 3d printing technology, and has been a popular choice for engineers and manufacturers for decades. invented in 1982 by a group of researchers at the university of texas at austin, sls refers to technology in which a high powered laser sinters a thin layer of powder from above to form a solid cross section of the desired geometry. Resolution comparison of hss and mjf. image via voxeljet. looking at some of the key tech specs, mjf systems have a maximum build volume of 380 x 294 x 380mm, while the voxeljet vx1000 hss. Sls and mjf are powder bed fusion technologies that create 3d parts from a thermoplastic powder. selective laser sintering (sls) uses a laser to melt and fuse powder grains, whereas multi jet fusion (mjf) employs a fusing agent, heat, and infrared light to fuse the powder. sls can employ a more comprehensive selection of materials – many of. Sls and mjf are both industrial technologies that offer high dimensional accuracy for your 3d printed parts. pa12 with sls. standard layer thickness: 100 – 120µm. accuracy: ± 0.3% (minimum of ± 0.3 mm) pa12 with mjf. standard layer thickness: 80µm.

Mjf And Sls 3d Prints Vapour Fused And Vapour Fused With Black Dyeing Sls and mjf are powder bed fusion technologies that create 3d parts from a thermoplastic powder. selective laser sintering (sls) uses a laser to melt and fuse powder grains, whereas multi jet fusion (mjf) employs a fusing agent, heat, and infrared light to fuse the powder. sls can employ a more comprehensive selection of materials – many of. Sls and mjf are both industrial technologies that offer high dimensional accuracy for your 3d printed parts. pa12 with sls. standard layer thickness: 100 – 120µm. accuracy: ± 0.3% (minimum of ± 0.3 mm) pa12 with mjf. standard layer thickness: 80µm.

Sls Vs Mjf Exploring The Differences

Mjf Vs Sls Youtube

Comments are closed.