Vol 28 Head Pressure Control Of Water Cooled Systems Evomart

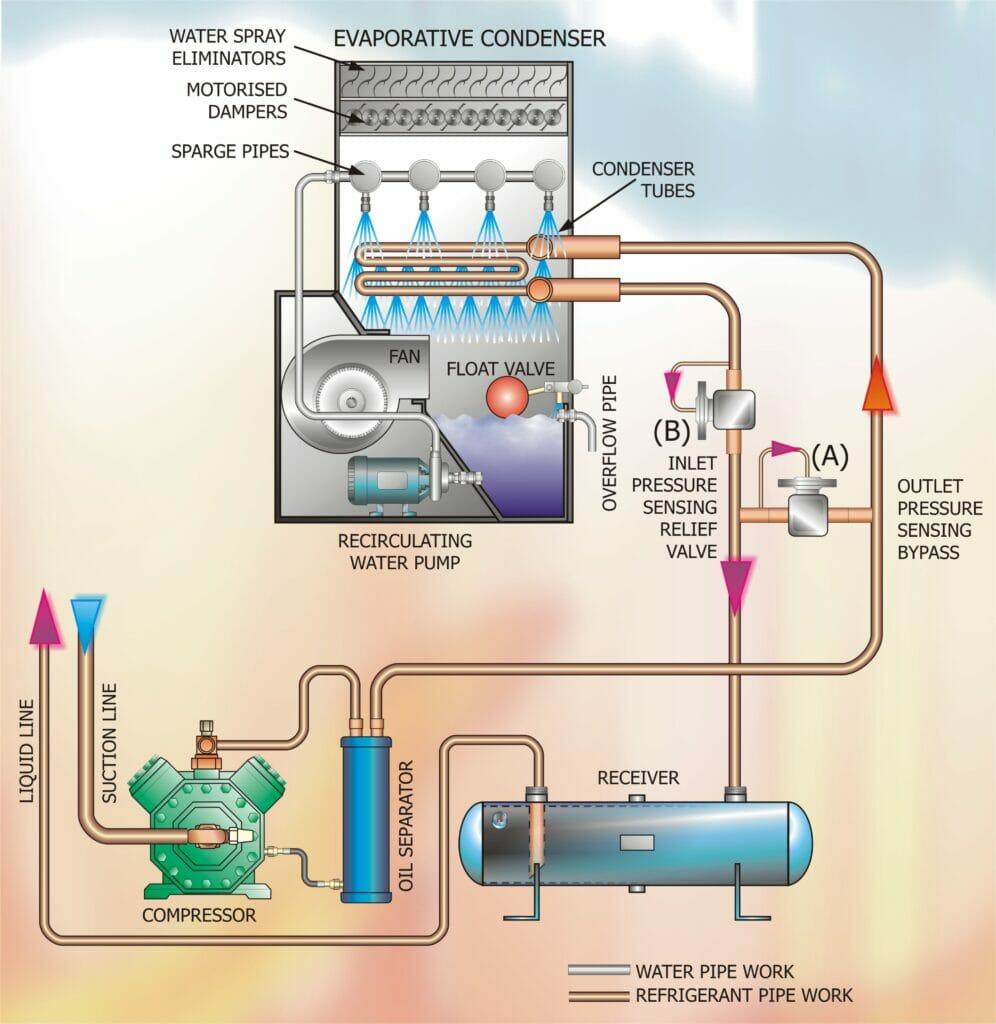

Vol 28 Head Pressure Control Of Water Cooled Systems Evomart The first step in controlling water temperature is at the cooling tower and this is achieved by controlling the volume of air circulated by the tower fans, either by dampers or by fan speed control, as described in evaporative condensers above. the second step is to force the water to recirculate by fitting a by pass valve between the condenser. The purpose of a heat anticipator is to . to control ice build up on a heat pump outdoor coil in the heating cycle, a is attached to a large diaphragm. a low pressure control has a "high event" and a "differential" setting. the technician wants the system to turn on at 28 psig and shut down at 2 psig.

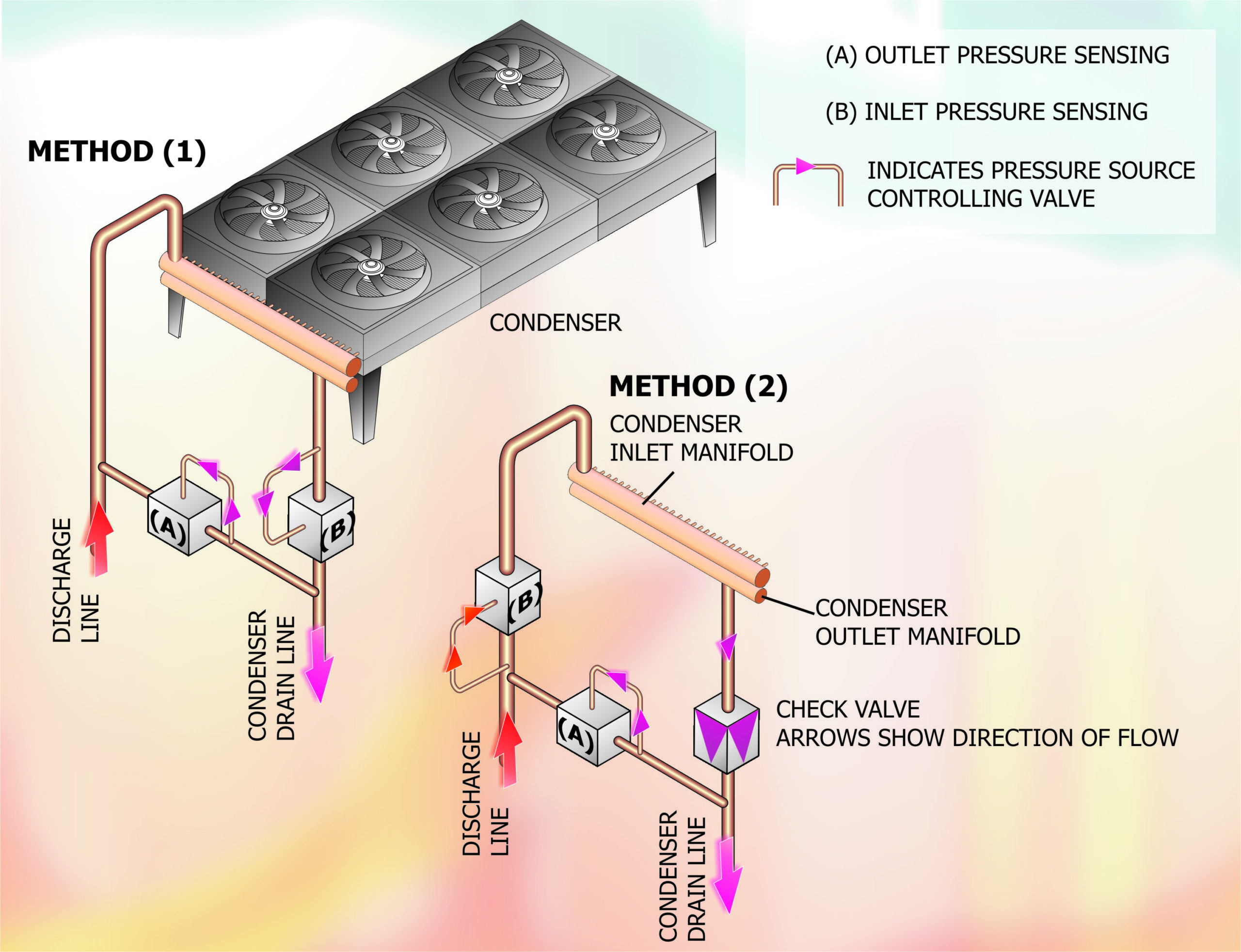

Vol 28 Head Pressure Control Of Water Cooled Systems Evomart Add three way mixing valve to condenser water supply to the chillers to bleed in the cold tower water. use vfd's on the condenser pumps and two way motor valves on the chillers condenser water intake. you can control the valves with a 0 10v analog signal form the chiller controller based on head pressure. Timisation– variable head pressure control for water cooled condensersthis month, we’ll look into the optimisation strategy of applying variable speed drive (vsd) controllers to pumps f. r head pressure control of single water cooled direct expansion (dx) units. by controlling the head pressure of water cooled condensers, you are able to. If the head pressure is allowed to fall below certain minimums,system performancecan be adversely affected in the following areas: 1. underfeeding tevs (thermostatic expansionvalves) and starving evaporators. 2. oil logging. 3. reduced compressor efficiency and higher dis charge temperatures. please see attached pdf for complete article. Ensure you have a full load no unloading. first charge the system with the minimum charge (or add refrigerant while the unit is running). adjust the head pressure control until you get 210 to 250 psi (r22). continue to add gas until your discharge superheat reaches 75f or less. do not go lower that 60f (overcharge).

Vol 28 Head Pressure Control Of Water Cooled Systems Evomart If the head pressure is allowed to fall below certain minimums,system performancecan be adversely affected in the following areas: 1. underfeeding tevs (thermostatic expansionvalves) and starving evaporators. 2. oil logging. 3. reduced compressor efficiency and higher dis charge temperatures. please see attached pdf for complete article. Ensure you have a full load no unloading. first charge the system with the minimum charge (or add refrigerant while the unit is running). adjust the head pressure control until you get 210 to 250 psi (r22). continue to add gas until your discharge superheat reaches 75f or less. do not go lower that 60f (overcharge). The component that varies the flow of water through a water cooled condenser to maintain a stable head pressure is called a (n) . water regulating valve. study with quizlet and memorize flashcards containing terms like a normally operating water cooled condenser is operating with a 10°f differential between water in and water out. When a system with a water cooled. condenser cycles off, the water regulating valve should. a. remain open during the off cycle. b. close, since the head pressure is lower. c. open all the way to remove any residual heat. d. re calibrate itself to maintain the new lower head pressure. answer :b.

Vol 27 Low Ambient Air Conditioning Control Methods Air Or Water Systems The component that varies the flow of water through a water cooled condenser to maintain a stable head pressure is called a (n) . water regulating valve. study with quizlet and memorize flashcards containing terms like a normally operating water cooled condenser is operating with a 10°f differential between water in and water out. When a system with a water cooled. condenser cycles off, the water regulating valve should. a. remain open during the off cycle. b. close, since the head pressure is lower. c. open all the way to remove any residual heat. d. re calibrate itself to maintain the new lower head pressure. answer :b.

Comments are closed.