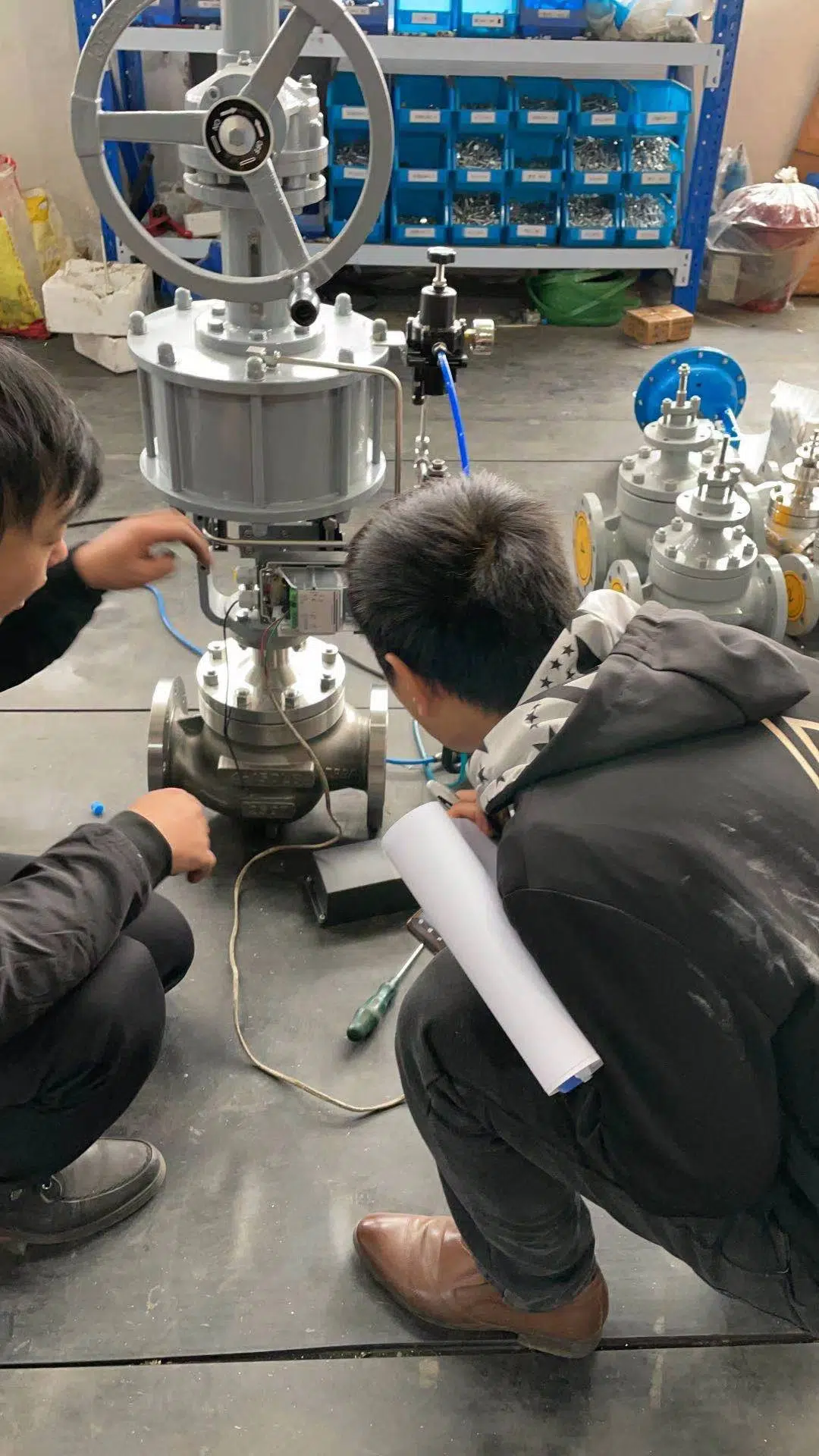

Valve Testing

Valve Testing Itis Typically, the valve is mounted on a test bench and partially opened. then, the shell is pressurized, with asme b16.34 recommending a minimum of 1.5 times the valve pressure rating at 100 ℉ (38 ℃) for hydrostatic testing. while that of pneumatic seat testing is 1.1 times the maximum allowable pressure. The valve inspection procedure ensures that the valve is free of defects and will meet the defined quality standards. there is a range of valve testing procedures. at hqts, we have over 25 years of experience in quality management, which includes quality assurance and quality control. we are a global company and can help with valve testing.

Valve Testing Itis Valve inspection and testing is an important subject for piping professionals as it ensures the integrity and performance of valves during plant operation. for smooth and safe operation of industrial processes, valve inspection and testing must be performed. Testing a valve needs to take into account its pressure class. api spec 6d. this is an international testing standard that applies to ball valves, check valves, and plug valves. it specifies the requirements and provides recommendations for the design, manufacture, testing, and documentation of valves. bs 759 1. Valve testing is a critical process in ensuring the safety and reliability of valves used in various industries. valves are mechanical devices that control the flow of fluids, such as liquids, gases, and slurries, through pipes and other passageways. they play a crucial role in regulating the flow rate, pressure, and direction of fluids, making. Api 598 covers the inspection, examination, and testing requirements for resilient seated, nonmetallic seated, and metal to metal seated gate, glove, plug, ball, check, and butterfly valves. it is relevant to examination and testing by the valve manufacturer, supplementary examinations performed at the valve manufacturer’s plant, and pressure.

Valve Testing And Inspection In Quality Control Explained Hqts Valve testing is a critical process in ensuring the safety and reliability of valves used in various industries. valves are mechanical devices that control the flow of fluids, such as liquids, gases, and slurries, through pipes and other passageways. they play a crucial role in regulating the flow rate, pressure, and direction of fluids, making. Api 598 covers the inspection, examination, and testing requirements for resilient seated, nonmetallic seated, and metal to metal seated gate, glove, plug, ball, check, and butterfly valves. it is relevant to examination and testing by the valve manufacturer, supplementary examinations performed at the valve manufacturer’s plant, and pressure. A pressure test in excess of the cold working pressure (cwp) rating of the valve for the purpose of validating the soundness and strength of the valve pressure containing structures. 3.9 visually detectable leakage leakage during a valve pressure test, either through or past a pressure boundary or closure member that is validated by normal vision. To support the quality inspection process, industry organizations develop and publish standards. two guiding standards for valve testing are api standard 5981 valve inspection and testing and mss standard practice sp 612. both standards define the terms and provide standards related to the inspection and testing of industrial valves.

Pressure Safety Valve Testing Pressure Testing Ralston Instruments A pressure test in excess of the cold working pressure (cwp) rating of the valve for the purpose of validating the soundness and strength of the valve pressure containing structures. 3.9 visually detectable leakage leakage during a valve pressure test, either through or past a pressure boundary or closure member that is validated by normal vision. To support the quality inspection process, industry organizations develop and publish standards. two guiding standards for valve testing are api standard 5981 valve inspection and testing and mss standard practice sp 612. both standards define the terms and provide standards related to the inspection and testing of industrial valves.

Valve Testing

Professional Valve Testing And Inspection

Comments are closed.