Using A Repair Coupling A 3 Vent Plumber Plumbing Soldering Diy Fyp

Using A Repair Coupling A 3 Vent Plumber Plumbing Soldering Diy About press copyright contact us creators advertise developers terms privacy policy & safety how works test new features nfl sunday ticket press copyright. A standard coupling (copper or pvc) has a divot or ridge to ensure each pipe gets pushed in the appropriate amount. repair couplings don't have that divot ridge, allowing it to be slid along the pipes easily before soldering cemented.

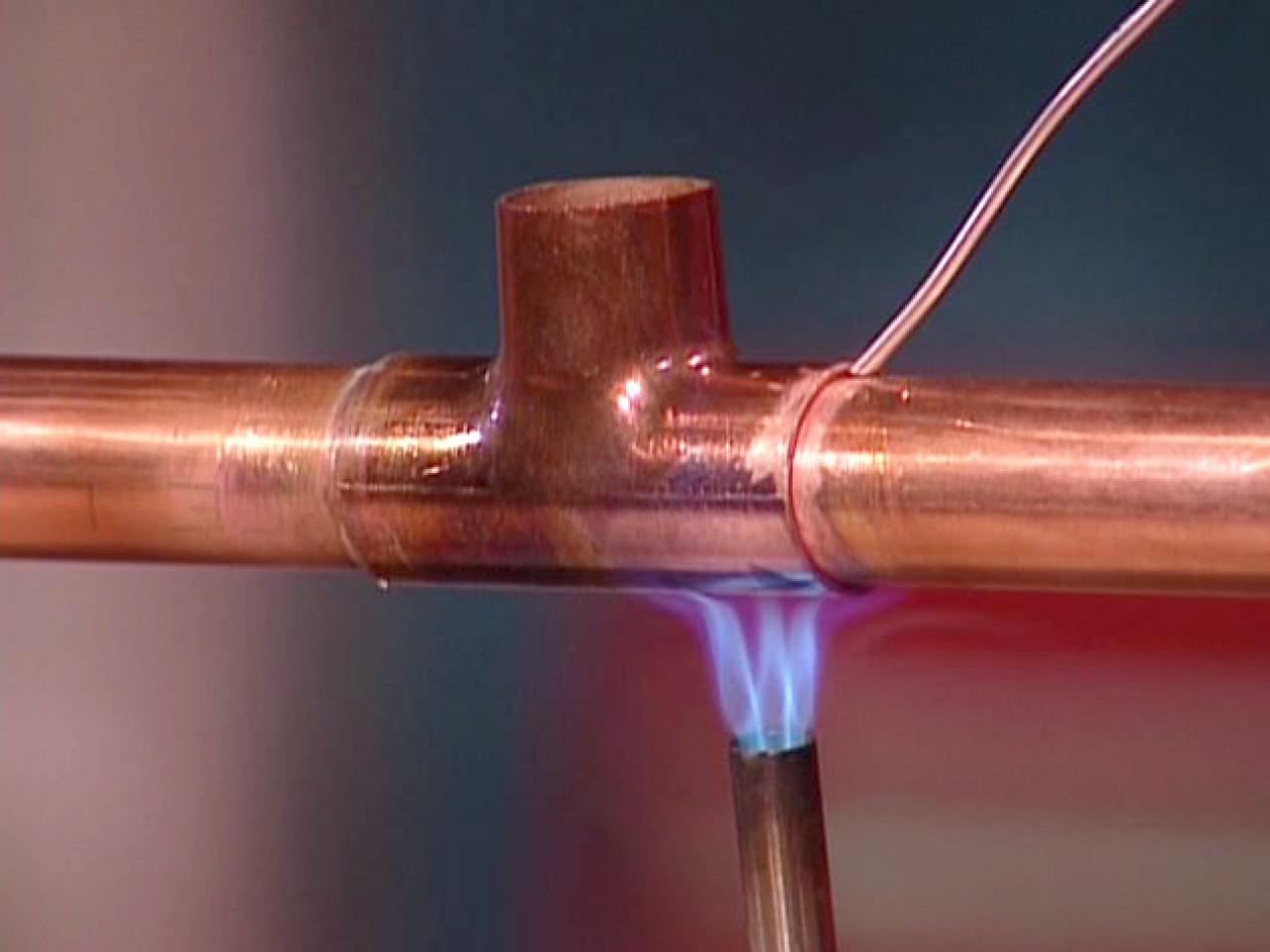

Using Repair Couplings Begginer R Plumbing Keep the threaded fitting pointed up, so that the solder will run away from the threads. if you have to solder a threaded fitting in place, be sure to wipe excess flux from around the joint after you assemble the pipe and fitting. extra flux can run down onto the threads, causing the solder to follow it. 8 10. Make sure you use emery cloth to clean the pipe really good and also use the wire brush to clean the inside of both sides of the coupling and apply flux. while you are heating the pipe, keep tapping the solder against it every few seconds until the solder starts to melt. that's the right temperature. After installing the two halves of the union, you join the pipes by bringing the union together and screwing the nut on one side to the threads on the other. this central connection is leakproof when fully tightened even without the use of plumbing tape or thread compound. when using unions for water connections, such as the water heater, it's. Step 1. when a copper pipe corrodes and leaks or bursts from freezing, you have to fix it fast. if the leak is pinhole sized and less than 1 2 in. of pipe must be removed, you can make the repair by cutting the pipe and soldering (“sweating”) on an ordinary pipe coupling. however, to repair longer sections, you’ll want to use a “sweat.

How To Solder A Proper Plumbing Connection 5 Steps With Pictures After installing the two halves of the union, you join the pipes by bringing the union together and screwing the nut on one side to the threads on the other. this central connection is leakproof when fully tightened even without the use of plumbing tape or thread compound. when using unions for water connections, such as the water heater, it's. Step 1. when a copper pipe corrodes and leaks or bursts from freezing, you have to fix it fast. if the leak is pinhole sized and less than 1 2 in. of pipe must be removed, you can make the repair by cutting the pipe and soldering (“sweating”) on an ordinary pipe coupling. however, to repair longer sections, you’ll want to use a “sweat. Apply a line of glue around the end of the copper pipe. insert the pipe into the fitting. rotate the pipe a full 360 degrees to spread the glue around the entire bond. allow the glue to dry per the manufacturer’s instructions before putting the pipe back in use. 1. disassemble a soldered joint. turn off the water. make sure the pipe is drained of any remaining water. ignite the propane torch and play the flame over the fitting until the old solder melts. quickly pull the pipe from the fitting. do this again to separate the other fitting. 2. clean the joint.

Soldering Joint Flux At Allison Tarvin Blog Apply a line of glue around the end of the copper pipe. insert the pipe into the fitting. rotate the pipe a full 360 degrees to spread the glue around the entire bond. allow the glue to dry per the manufacturer’s instructions before putting the pipe back in use. 1. disassemble a soldered joint. turn off the water. make sure the pipe is drained of any remaining water. ignite the propane torch and play the flame over the fitting until the old solder melts. quickly pull the pipe from the fitting. do this again to separate the other fitting. 2. clean the joint.

How To Solder Copper Pipe Complete Guide Plumbing 101 Youtube

Plumber Soldering Stock Image Image Of Flames Repairs 142673

Comments are closed.