Types Of Orthodontic Wires Video 1

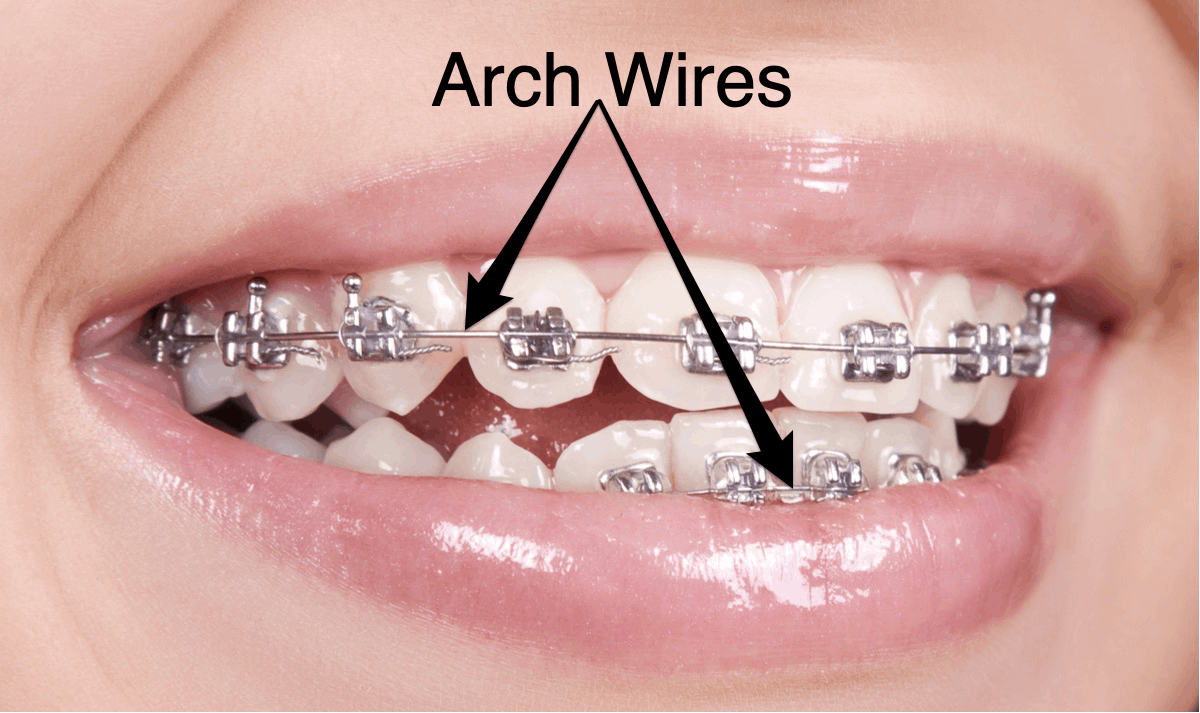

Types Of Orthodontic Wires Video 1 Youtube Braces consist of several components, including brackets, bands, and archwires. archwires, which are the focus of today's discussion, are the framework that. Rubber band: larger elastic bands attach to the top and bottom jaw to fix overbites and underbites, applying pressure to the jaws to move them into their proper positions. wire types: stainless steel alloy, beta titanium, & nickel titanium. arch wires come in three types of metals: stainless steel, beta titanium, and nickel titanium alloys.

Different Wire Sizes For Braces At Matthew Amundsen Blog Now that you understand a little about why orthodontists like elastic wires in the beginning of braces treatment and stronger, stiffer wires at the end of treatment, let us consider what materials the arch wires are made of. there are three main types of material compositions for arch wires: 1) stainless steel; 2) nickel titanium (ni ti); and 3. Archwires fit into the slots in the brackets and are responsible for actually moving your teeth. without an archwire, you’d be wearing the brackets of braces but they wouldn’t help move or straighten your teeth. it is called archwire because your top teeth make up your top arch and your bottom teeth make up your lower arch. archwires come. These wires can be soldered and welded for the fabrication of complex appliances, although it is necessary to use solder to provide reinforcement to the weld joints. the stainless steel alloys used for orthodontic wires are of the “18–8” austenitic type, containing approximately 18% chromium and 8% nickel (table 4. 1). Orthodontic archwires have significantly changed within the last 20 years. 1 archwire material has evolved from gold wires, to various stainless steel, as well as nickel, beta, and copper titanium wires. the shape of archwires has also evolved from round, square, and rectangular to recent beveled surfaces. there have also been significant arch.

Placing A Stainless Steel Ligature Wire For Braces Youtube These wires can be soldered and welded for the fabrication of complex appliances, although it is necessary to use solder to provide reinforcement to the weld joints. the stainless steel alloys used for orthodontic wires are of the “18–8” austenitic type, containing approximately 18% chromium and 8% nickel (table 4. 1). Orthodontic archwires have significantly changed within the last 20 years. 1 archwire material has evolved from gold wires, to various stainless steel, as well as nickel, beta, and copper titanium wires. the shape of archwires has also evolved from round, square, and rectangular to recent beveled surfaces. there have also been significant arch. Load deflection curve: used to analyse the behaviour and characteristics of the wires; types of orthodontic archwires and classification. for the orthodontic archwire to do its job properly, it must fit perfectly. in this respect, there are different classes, which are defined by cross section, composition, thickness and material, among others. Discussed at the second international orthodontic congress in 1931, 1 stainless steel began to replace gold as orthodontists’ wire of choice and, by 30 years later, it had totally eclipsed the use of gold. orthodontics in the 1960s saw the introduction of cobalt chromium alloy wires. 2 nitinol, a new alloy of nickel and titanium, was adapted.

All About Orthodontic Arch Wires Archwired Load deflection curve: used to analyse the behaviour and characteristics of the wires; types of orthodontic archwires and classification. for the orthodontic archwire to do its job properly, it must fit perfectly. in this respect, there are different classes, which are defined by cross section, composition, thickness and material, among others. Discussed at the second international orthodontic congress in 1931, 1 stainless steel began to replace gold as orthodontists’ wire of choice and, by 30 years later, it had totally eclipsed the use of gold. orthodontics in the 1960s saw the introduction of cobalt chromium alloy wires. 2 nitinol, a new alloy of nickel and titanium, was adapted.

What Are Orthodontic Wires Made Of At Marcie Fillmore Blog

Comments are closed.