Types Of Flanges With Images Engineering Learner

Types Of Flanges With Images Engineering Learner 3. raised face (rf) these are the types of flanges which have a small raised section near the bore with an inside bore circle gasket. 4. male & female (m&f) these types of flanges are quite similar to the tongue and groove flanges which uses a matching pair of grooves and raised sections in order to secure the gasket. These flanges are commonly used in high pressure and high low temperature applications. there are two types of welding neck flanges: a regular type for use with pipes and an elongated type for use in process plants. by preventing pressure drops, turbulence, and erosion corrosion of metals near flanged joints are prevented. #2 long welding neck.

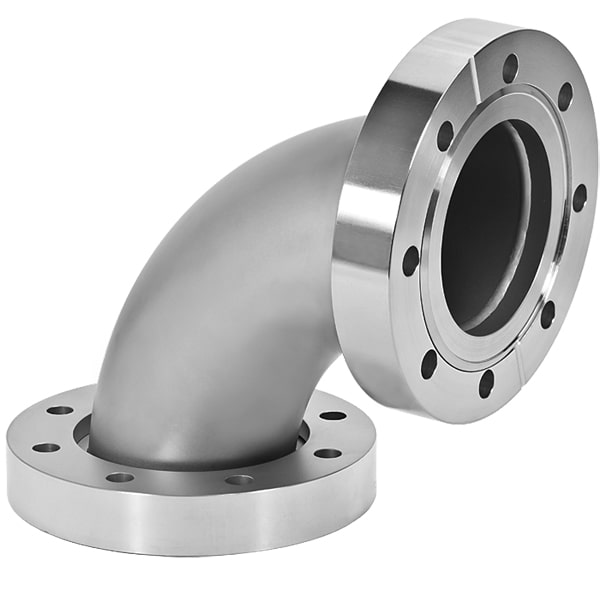

Types Of Flanges Design Functions Flange Face With Pictures 1. welding neck flange. the welding neck flanges consist of a long tapered hub. this tapered hub goes inside the pipe, whereas the flange’s other end is joined with the pipe or pipe fittings using butt welding. welding neck type of flange has applications in high temperature and pressure applications. 2. The various types of flanges utilized in pipe systems are described below according to their diameters and other variables: 1. slip on flange. a slip on flange is a flange that attaches to a pipe or fitting via two fillet welds, one within the flange cavity and the other outside the flange. fig 1: slip on flange. Types of flanges. in this article, we review the 13 types of flanges for pipelines and piping systems (asme b16.5), divided into “standard” and “non standard” (or less common) types. large flange sizes, not examined here, are ruled by the asme b16.47 series a b specification. classification of asme flanges b16.5:b16.47 & special flanges. Threaded or screwed flange. threaded flanges are joined to pipes by screwing the pipe and are used on piping systems that prohibit direct welding on the pipe. usually, threaded flanges are used for galvanized piping. industrial threaded flanges are made in sizes up to 4 inches with various pressure ratings.

Types Of Flanges Design Functions Flange Face With Pictures Types of flanges. in this article, we review the 13 types of flanges for pipelines and piping systems (asme b16.5), divided into “standard” and “non standard” (or less common) types. large flange sizes, not examined here, are ruled by the asme b16.47 series a b specification. classification of asme flanges b16.5:b16.47 & special flanges. Threaded or screwed flange. threaded flanges are joined to pipes by screwing the pipe and are used on piping systems that prohibit direct welding on the pipe. usually, threaded flanges are used for galvanized piping. industrial threaded flanges are made in sizes up to 4 inches with various pressure ratings. Neck flat welding flanges with a nominal pressure of 0.25~2.5mpa use a convex and concave sealing surface. 12. asme butt welding flanges. asme flanges are components used to connect pipes together, attached to the end of each pipe. there are two methods for producing asme butt welding flanges: forging and casting. 1. weld neck flanges: weld neck flanges are the most common type and feature a long neck that is welded to the pipe. this design provides excellent strength and durability, making them suitable for high pressure and high temperature applications. 2. slip on flanges: slip on flanges have a slightly larger diameter than the pipe, allowing them to.

Types Of Flanges Design Functions Flange Face With Pictures Neck flat welding flanges with a nominal pressure of 0.25~2.5mpa use a convex and concave sealing surface. 12. asme butt welding flanges. asme flanges are components used to connect pipes together, attached to the end of each pipe. there are two methods for producing asme butt welding flanges: forging and casting. 1. weld neck flanges: weld neck flanges are the most common type and feature a long neck that is welded to the pipe. this design provides excellent strength and durability, making them suitable for high pressure and high temperature applications. 2. slip on flanges: slip on flanges have a slightly larger diameter than the pipe, allowing them to.

Types Of Flanges Design Functions Flange Face With Pictures

Comments are closed.