Time And Temperature Controls During Unrefrigerated Processing

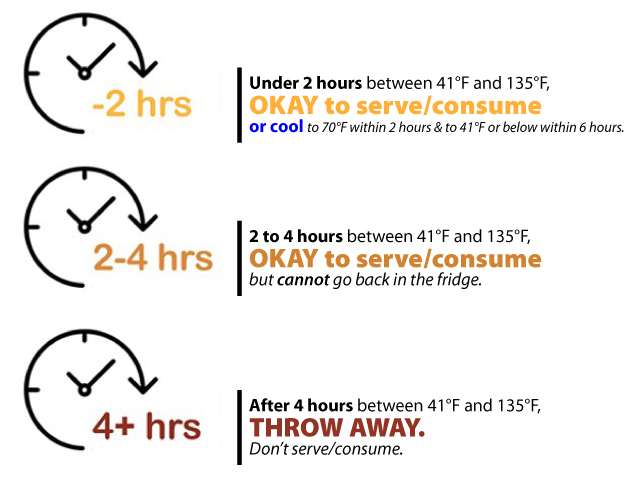

Time And Temperature Controls During Unrefrigerated Processing Youtube During that time, the highest ambient temperature was 65 degrees fahrenheit and the internal temperature of the fish was over 50 degrees for 4 hours. based on this information,. During processing from the air, unclean hands, practical considerations for unrefrigerated processing . for time and temperature control. table a 2 (appendix 4) can.

Ppt Part Ii Good Manufacturing Practices Gmp Powerpoint Time and temperature controls during unrefrigerated processing discusses how to control pathogen growth during unrefrigerated processing of raw ready to eat and cooked ready to eat seafood. This video presents fda’s recommendations for controlling time and temperature exposures during unrefrigerated processing of seafood. it discusses common ba. Time and temperature controls during unrefrigerated processing discusses how to control pathogen growth during unrefrigerated processing of raw ready to eat and cooked ready to eat seafood products. this video also includes discussions on evaluating time and temperature exposures during unrefrigerated processing and developing time temperature. For time and temperature controls during transit, storage, cooling after cooking, and unrefrigerated processing, refer to the previous section. aquaculture drugs (chapter 11) the primary processor is responsible for applying controls during production and tran sit. more approved drugs have been added. transporting live fish is now recognized as.

Time And Temp Control Foods Designated Contact Roll N Pin Catering Time and temperature controls during unrefrigerated processing discusses how to control pathogen growth during unrefrigerated processing of raw ready to eat and cooked ready to eat seafood products. this video also includes discussions on evaluating time and temperature exposures during unrefrigerated processing and developing time temperature. For time and temperature controls during transit, storage, cooling after cooking, and unrefrigerated processing, refer to the previous section. aquaculture drugs (chapter 11) the primary processor is responsible for applying controls during production and tran sit. more approved drugs have been added. transporting live fish is now recognized as. Time temperature indicators; time and temperature controls during unrefrigerated processing; secondary processor receiving and storage controls; heat process validation; primary processor scombrotoxin controls overview and testing at receiving; primary processor scombrotoxin controls harvest vessel records; seafood haccp compendium (includes:). The video series consists of six parts and discusses concepts taken from the fda’s “fish and fishery products hazards and controls guidance.”. the topics tackled by the series include: time temperature indicators; time and temperature controls during unrefrigerated processing; secondary processor receiving and storage controls; heat.

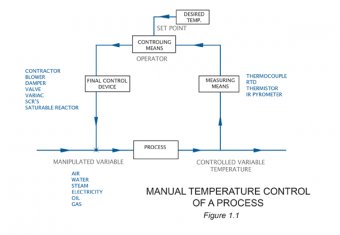

Temperature Control Loop P Id General Knowledge Facts Process Flow Time temperature indicators; time and temperature controls during unrefrigerated processing; secondary processor receiving and storage controls; heat process validation; primary processor scombrotoxin controls overview and testing at receiving; primary processor scombrotoxin controls harvest vessel records; seafood haccp compendium (includes:). The video series consists of six parts and discusses concepts taken from the fda’s “fish and fishery products hazards and controls guidance.”. the topics tackled by the series include: time temperature indicators; time and temperature controls during unrefrigerated processing; secondary processor receiving and storage controls; heat.

Processing Temperature Vs Processing Time For Bulk Ti Samples

Automatic Temperature Control Systems Control Systems

Comments are closed.