Thread Identification O Ring Face Seal

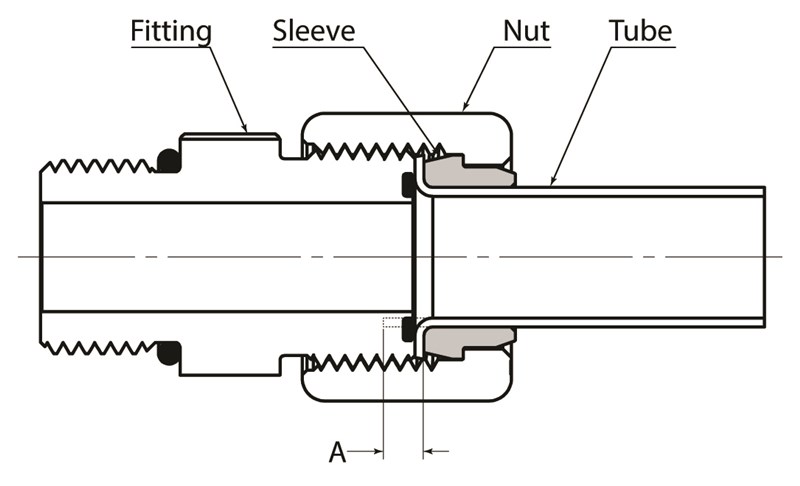

Thread Identification Guide Hoseandfittings Confirm face seal o ring is properly installed. step 2: lubricate the threads and the o ring with your systems hydraulic fluid or a light lubricant. step 3: align mating face seal flange against o ring and finger tighten face seal flange nut. step 4: torque flange nut to the value shown in the table on the left hand side of this page. In this video, our gates hydraulics experts go through the process of identifying the thread on an o ring face seal seal type. to identify seals remember thi.

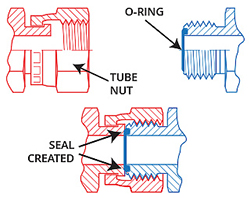

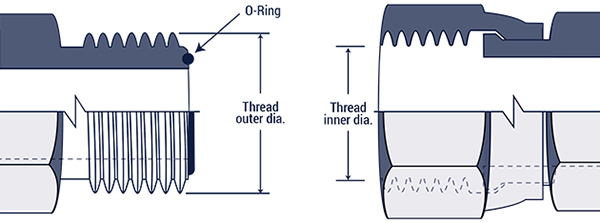

Surplus Center O ring face seal (orfs) this connection offers the very best leakage control available today. the male connector has a straight thread and o ring in the face. the female has a straight thread and a machined flat face. the seal takes place by compressing the o ring onto the flat face of the female, similar to a flange type fitting. the threads hold. Sae straight thread o ring (o ring boss) sae j1926 1 and iso 11296 1. the male connector of the o ring boss has an o ring and a straight thread. the female port has a sealing face, a chamfer, and a straight thread. the o ring is compressed into the chamfer to form a seal. the threads of the two halves engage to form a mechanically strong. The male connector has a straight thread and an o ring in the face. the j1453 (orfs) o ring face seal connections are considered the best for leak female has a straight thread and a machined flat face. the seal takes place by compressing the o ring onto the flat face of the female, similar to the split flange type fitting. Sometimes referred to as “o ring boss,” the male connector has a straight thread and an o ring. the female port has a straight thread, a machined surface (minimal spotface) and a chamfer to ac cept the o ring. the seal takes place by compressing the o ring into the chamfer. the threads hold the connection mechanically. inch size dash size.

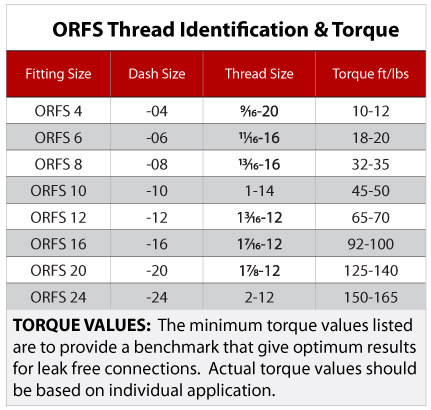

Thread Identification Guide Hoseandfittings The male connector has a straight thread and an o ring in the face. the j1453 (orfs) o ring face seal connections are considered the best for leak female has a straight thread and a machined flat face. the seal takes place by compressing the o ring onto the flat face of the female, similar to the split flange type fitting. Sometimes referred to as “o ring boss,” the male connector has a straight thread and an o ring. the female port has a straight thread, a machined surface (minimal spotface) and a chamfer to ac cept the o ring. the seal takes place by compressing the o ring into the chamfer. the threads hold the connection mechanically. inch size dash size. Face type seals the face seal design chart below explains the hardware dimensions to use for an o ring seal when the groove is cut into a flat surface. for designing systems which contain internal pressure, like the example below, the groove's outside diameter (od) is primary, and the groove's width then determines the inside diameter. Seal and is one of the best choices for a leak free connection.as the name implies, o ring face seal (orfs) fittings incorporate an o ring at the face of the fitting and are. designed to eliminate leaks in high pressure hydraulic systems. made to sae j1453 standard, orfs connections typically use buna n or viton, 90 duro.

O Ring Face Seal Fittings And Parker Flat Face O Ring Hydraulic Fitting Face type seals the face seal design chart below explains the hardware dimensions to use for an o ring seal when the groove is cut into a flat surface. for designing systems which contain internal pressure, like the example below, the groove's outside diameter (od) is primary, and the groove's width then determines the inside diameter. Seal and is one of the best choices for a leak free connection.as the name implies, o ring face seal (orfs) fittings incorporate an o ring at the face of the fitting and are. designed to eliminate leaks in high pressure hydraulic systems. made to sae j1453 standard, orfs connections typically use buna n or viton, 90 duro.

Steel O Ring Face Seal Fittings Steel O Ring Face Seal Fittings

The Different Between O Ring Boss And O Ring Face Sealing Sae Fittings

Comments are closed.