The Second Pillar Of Lean Continuous Improvement Blog

The Second Pillar Of Lean Continuous Improvement Blog Lean spends a great amount of time emphasizing the importance of the people. whether this be through mutual respect, humility, systems thinking, equality among ranks, coaching, teamwork, active listening, conflict management… the list truly goes on and on. this is exactly why toyota made “respect for people” as one of two pillars. The two lean pillars aim to emphasize everyone's input and build an organizational culture of embracing changes. in other words, let the people drive the improvement through constant learning and experimenting. building an organizational mindset where change is embraced is what would put you always one step ahead in the game.

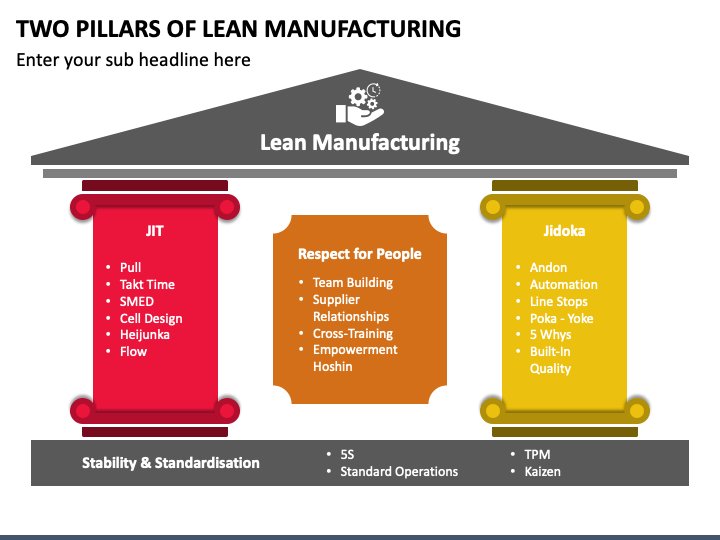

2 Pillars Of Lean House Kaizen events: these are focused, short term improvement activities where cross functional teams work together to tackle specific problems or opportunities for improvement. pillar 2: respect for people. the second pillar of lean, respect for people, underscores the importance of valuing and developing employees at all levels within an organization. In fact, these two pillars directly inform lean’s five principles: identifying value. mapping the value stream. creating flow. pulling instead of pushing. pursuing perfection. following the continuous improvement framework, teams constantly search for greater value and study the processes and methods that deliver it. Continuous improvement is largely, though not entirely, an affair of the 'rational mind', which some people call the 'left brain'. we need to know the fundamentals, including value waste, 5 s, visual management, standardized work & the like. A key aspect of implementing continuous improvement is the use of lean tools such as value stream mapping, 5s, and pdca (plan do check act) cycles, which provide a structured template for analyzing processes and implementing improvements. respect for people, the second pillar, emphasizes the importance of human elements in the workplace.

What Is Lean Management Continuous improvement is largely, though not entirely, an affair of the 'rational mind', which some people call the 'left brain'. we need to know the fundamentals, including value waste, 5 s, visual management, standardized work & the like. A key aspect of implementing continuous improvement is the use of lean tools such as value stream mapping, 5s, and pdca (plan do check act) cycles, which provide a structured template for analyzing processes and implementing improvements. respect for people, the second pillar, emphasizes the importance of human elements in the workplace. The two pillars of lean are continuous improvement (also called kaizen in japanese term) and respect for people. the real value of continuous improvement is in building organizational culture of continuous learning. respect for people is the foundation of team work and collaboration. i highlight some points i think are critical for establishing. Lean methodology is a business philosophy that helps project managers improve their business practices while eliminating waste. this philosophy leans on two pillars: respect for people and continuous improvement. to aid these efforts, lean methodology focuses on the following five key principles: identify value. create a value stream map.

Two Pillars Of Lean Manufacturing Powerpoint Template Ppt Slides The two pillars of lean are continuous improvement (also called kaizen in japanese term) and respect for people. the real value of continuous improvement is in building organizational culture of continuous learning. respect for people is the foundation of team work and collaboration. i highlight some points i think are critical for establishing. Lean methodology is a business philosophy that helps project managers improve their business practices while eliminating waste. this philosophy leans on two pillars: respect for people and continuous improvement. to aid these efforts, lean methodology focuses on the following five key principles: identify value. create a value stream map.

What Are The 5 Lean Management Principles Iterators

Comments are closed.