The Dmaic Methodology For Six Sigma Quality Management Download

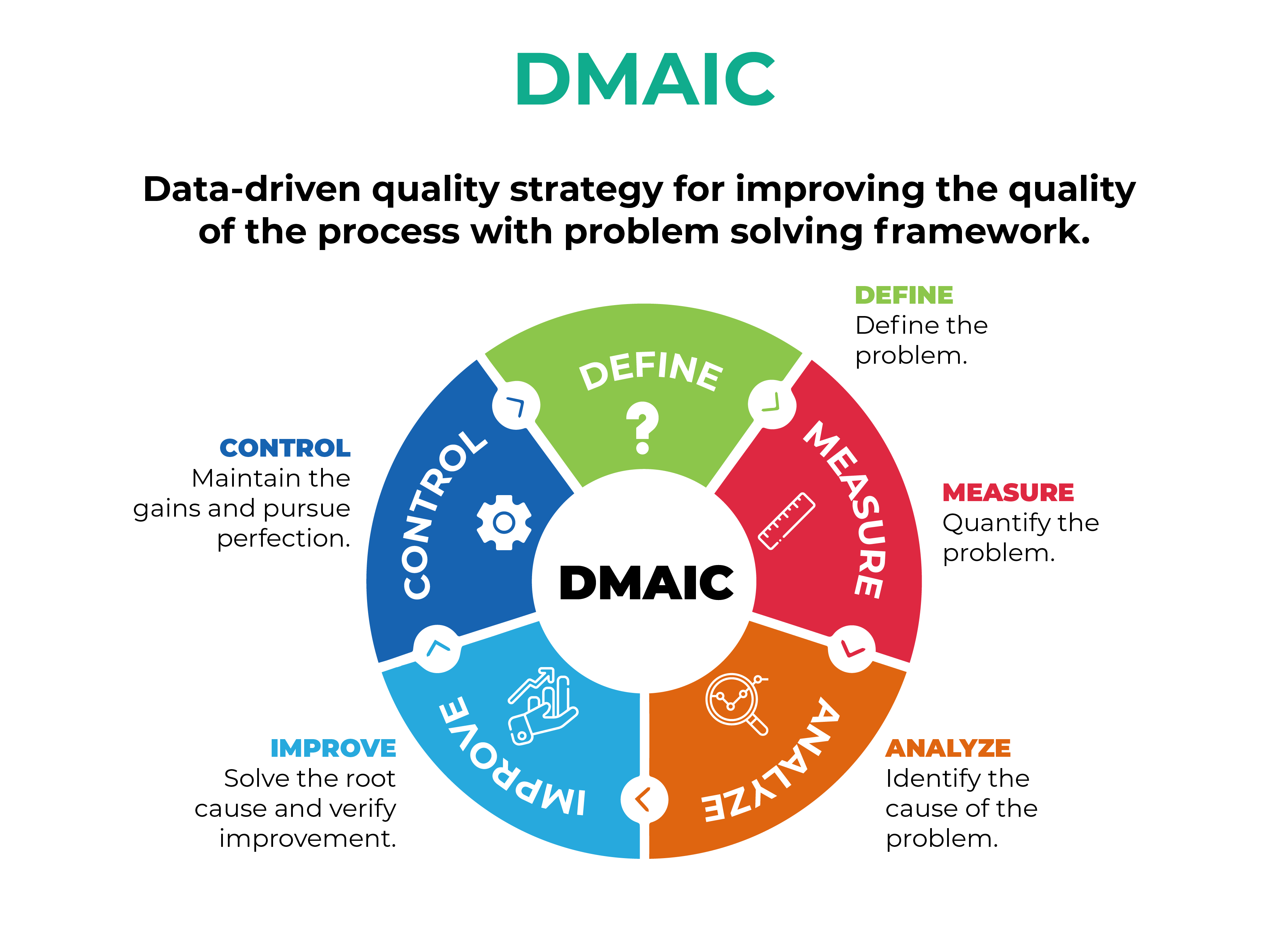

Dmaic Method In Six Sigma 5 Phases Complete Overview Artofit Dmaic is an acronym that stands for define, measure, analyze, improve, and control. it represents the five phases that make up the process: define the problem, improvement activity, opportunity for improvement, the project goals, and customer (internal and external) requirements. project charter to define the focus, scope, direction, and. Lean six sigma is simply a process for solving a problem. it consists of five basic phases: define, measure, analyze, improve, and control. this process is also known as dmaic (pronounced “duh may ik”), its acronym. lean and six sigma complement each other.

Six Sigma Dmaic Methodology Six sigma reduces variation within and across the value adding steps in a process. dmaic identifies key requirements, deliverables, tasks, and standard tools for a project team to utilize when tackling a problem. brief description of dmaic applications this classic or traditional six sigma methodology was designed to solve a. The six sigma training and certification levels are borrowed from the martial arts. the certification or belt levels include white, yellow, green, black and master black belt designations. master black belt. a master black belt is classically trained in statistical tools, six sigma methodology and management processes. By reviewing the example and following the five steps of the dmaic process – define, measure, analyze, improve and control – businesses can create meaningful changes in their operations. the dmaic process is a powerful tool applicable to any industry. learn the 5 steps of the six sigma dmaic process and review our example. Produce problem free projects. tackle issues efficiently and effectively with a customizable dmaic lean six sigma tool. structure your solutions: simplify complex conundrums with strictly defined guidelines. streamline your comms: improve team and organization wide communication to guarantee alignment. stay on topic: resolve the right issue.

The Dmaic Methodology For Six Sigma Quality Management Download By reviewing the example and following the five steps of the dmaic process – define, measure, analyze, improve and control – businesses can create meaningful changes in their operations. the dmaic process is a powerful tool applicable to any industry. learn the 5 steps of the six sigma dmaic process and review our example. Produce problem free projects. tackle issues efficiently and effectively with a customizable dmaic lean six sigma tool. structure your solutions: simplify complex conundrums with strictly defined guidelines. streamline your comms: improve team and organization wide communication to guarantee alignment. stay on topic: resolve the right issue. Dmaic is a five phase methodology used to solve complex problems and improve processes. let’s delve into each phase: 1. define: objective: clearly define the problem or opportunity for improvement. project charter: create a project charter that outlines the problem, objectives, scope, and expected benefits. stakeholder analysis: identify key. Dmaic is the problem solving approach that drives lean six sigma. it’s a five phase method—define, measure, analyze, improve and control—for improving existing process problems with unknown causes. dmaic is based on the scientific method and it’s pronounced “duh may ik.”. to build your understanding of the method, and help you apply.

Comments are closed.