Steel Connections Bolt Welds Steel Structural Design

Steel Connections Engineering Discoveries 2.1.2 welded connections (shear and or tension connections) 3 2.1.3 recommendation for fin plate connections 3 2.2 moment resisting connections 4 2.2.1 bolted connections (moment resisting connections) 4 2.2.2 welded connections (moment resisting connections) 4 2.3 design steps for simple connections – bolted connections 4. • 6520 ‐aws d1.1 structural welding code tests 6600 • 6610‐steel construction bma engineering, inc. – 6000 1 • 6620 6630 ‐nureg‐0800 rg 1.94 6300. design ‐ 6320. structural steel connections, joints and details • general provisions (section nj1) • types of structural welds and their applications.

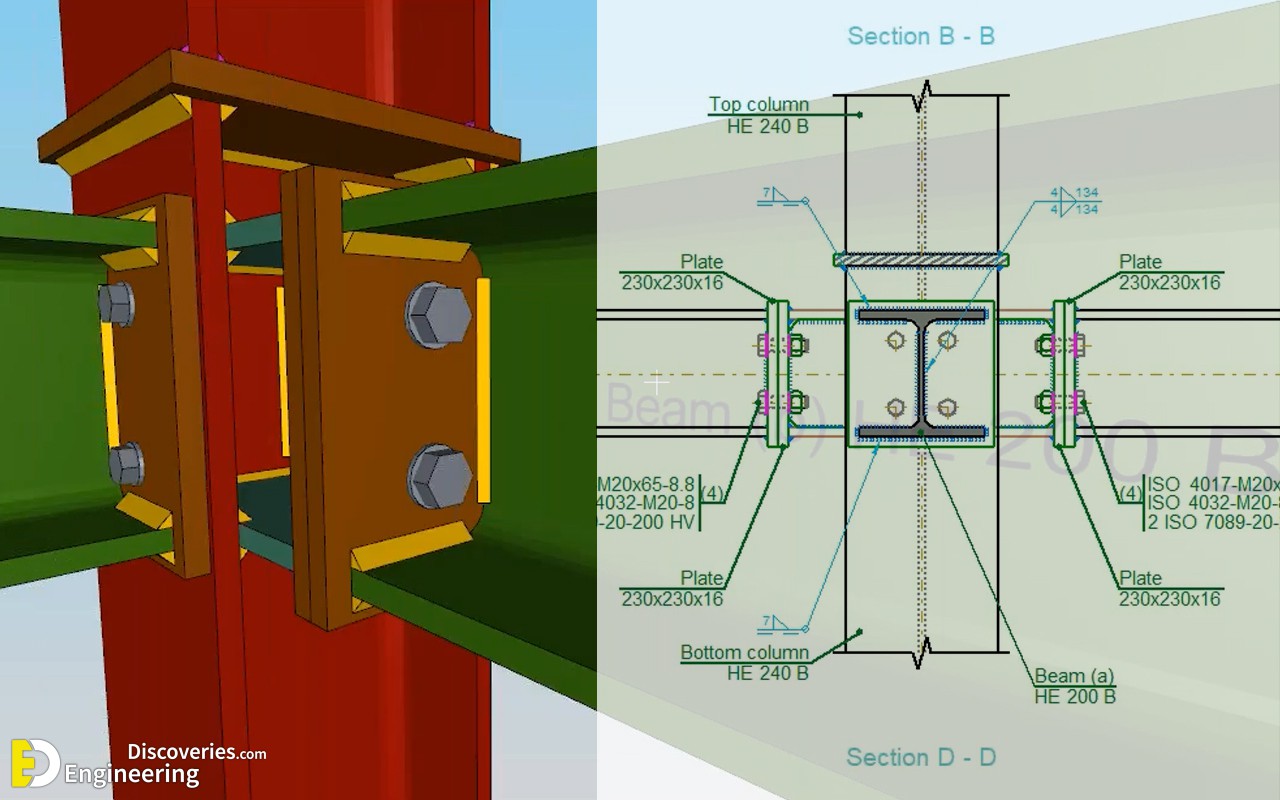

Steel Connection Design Part 2 Bolts And Welds Youtube And safe practices related to the design and installation of bolted structural connections. the research council’s specifications have been endorsed by the industrial fasteners institute and endorsed and published by the american institute of steel construction, and they form the basis of the technical requirements of other national standards. If the weld is too big, it can overheat the area and cause local damage. the maximum size of the weld needs to be 3 4 of the thinner plate. for example, if you connect two 10 mm plates, the weld should be at most 7 8 mm. this rule assumes that the weld is from both sides of the plate and it is a full length weld. Idea statica connection can design all types of welded or bolted connections, base plates, footing and anchoring. it provides precise checks, results of strength, stiffness and buckling analysis of a steel joint. bolts, welds and concrete blocks are checked according to the ec aisc cisc code. templates for most used connections are. 2.1.2 welded connections (shear and or tension connections) 3 2.1.3 recommendation for fin plate connections 3 2.2 moment resisting connections 4 2.2.1 bolted connections (moment resisting connections) 4 2.2.2 welded connections (moment resisting connections) 4 2.3 design steps for simple connections – bolted connections 4.

Steel Connections Design Guidelines Steelexplained Idea statica connection can design all types of welded or bolted connections, base plates, footing and anchoring. it provides precise checks, results of strength, stiffness and buckling analysis of a steel joint. bolts, welds and concrete blocks are checked according to the ec aisc cisc code. templates for most used connections are. 2.1.2 welded connections (shear and or tension connections) 3 2.1.3 recommendation for fin plate connections 3 2.2 moment resisting connections 4 2.2.1 bolted connections (moment resisting connections) 4 2.2.2 welded connections (moment resisting connections) 4 2.3 design steps for simple connections – bolted connections 4. Beam to beam connections. beam to beam connections are used to join beams, creating continuous spans that support roof structures, floor systems, or other elements of a building. these connections can be made through bolting or welding, depending on the structural requirements and design preferences. the choice between bolting and welding. In modern times, the most common types of connecting mediums are welds and bolts. welds offer simplicity, whilst bolts off economical installation in the field. rivets have historically been used, but have been mostly replaced by bolts for a number of reasons. these include: bolted connections: the most economical option but also the least.

Comments are closed.