Shop Tour Part 2 Lathe Machine

Hightower Custom Cues Shop Tour 2 Hightower Custom Cues 13:02 machine shop tips #25 acme threading part 2 tubalcainmrpete22222,701 views 1 year agothis is part 2 of a 2 part series on cutting an external acme thread on the clausing lathe. 11:44 machine shop tips #23 internal threading on the lathe tubalcainmrpete22261,591 views 1 year agoto access a complete listing of all my shop videos click on. As mentioned earlier, a 13 x 35.25 cnc lathe from cnc masters with all the bells and whistles you’ll need to get started is priced at $10,695. small cnc mini lathes are $2,000 to $9,000, while most two axis models range from $15,000 to $50,000. large production lathes can go as high as $300,000 or more.

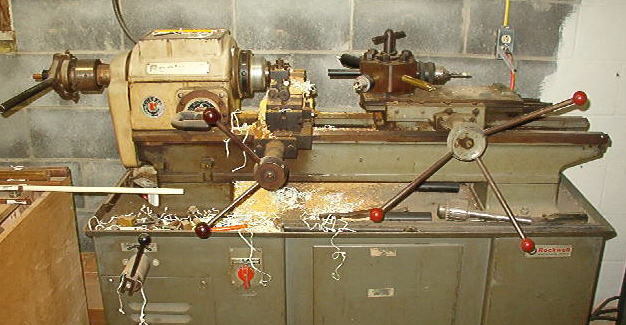

Welcome To My Machine Shop Pt 2 Abom79 Shop Tour Youtube Clausing lathe. this machine is fitted with a porter cable router and a slotting bit which does the cutting. for every rotation, the tool gives 6 cuts and is spinning at 28,000 rpm. all of that jargon equals a smooth finish on everything cut here. the machine is perfect for turning wood from square to round, tapering butts, forearms or whatever. Modern metal lathe a watchmaker using a lathe to prepare a component cut from copper for a watch. a lathe ( l eɪ ð ) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about. The facing tool is a bit more complicated to work with than other lathe tools, and you will spend a bit more time perfecting this. 14. drive plate. a drive plate is attached to the spindle nose on a lathe. the drive plate is usually circular and will help ensure that the workpiece stays properly in place. The machine structure may also be designed to minimize thermal growth. this is part one of a four part series about buying turning machines. part 2: buying a lathe: turrets and live tooling. part 3: buying a lathe: spindles and tailstocks. part 4: buying a lathe: slant beds and multitasking configurations.

Shop Tour Part 2 Machines And Tools Youtube The facing tool is a bit more complicated to work with than other lathe tools, and you will spend a bit more time perfecting this. 14. drive plate. a drive plate is attached to the spindle nose on a lathe. the drive plate is usually circular and will help ensure that the workpiece stays properly in place. The machine structure may also be designed to minimize thermal growth. this is part one of a four part series about buying turning machines. part 2: buying a lathe: turrets and live tooling. part 3: buying a lathe: spindles and tailstocks. part 4: buying a lathe: slant beds and multitasking configurations. A lathe machine is the “ mother of machining. ” it spins your workpiece and slices it to your desired shape with a stationary cutting tool. it’s an important part of the machining process. a lathe comprises a headstock, tailstock, bed, carriage, feed rod, lead screw, handwheel, and chip pan. all other parts are located inside these main. The engine lathe: this is the common kind which is found in small machine shop and in schools. it is the kind we will spend our time studying. it is not used for mass production of many parts, but for small jobs where a lesser number of parts is needed. b. the turret lathe: this lathe is used for mass producing parts.

Comments are closed.