Shoemaking 150 Manufacturing Steps To Make The Perfect Shoe

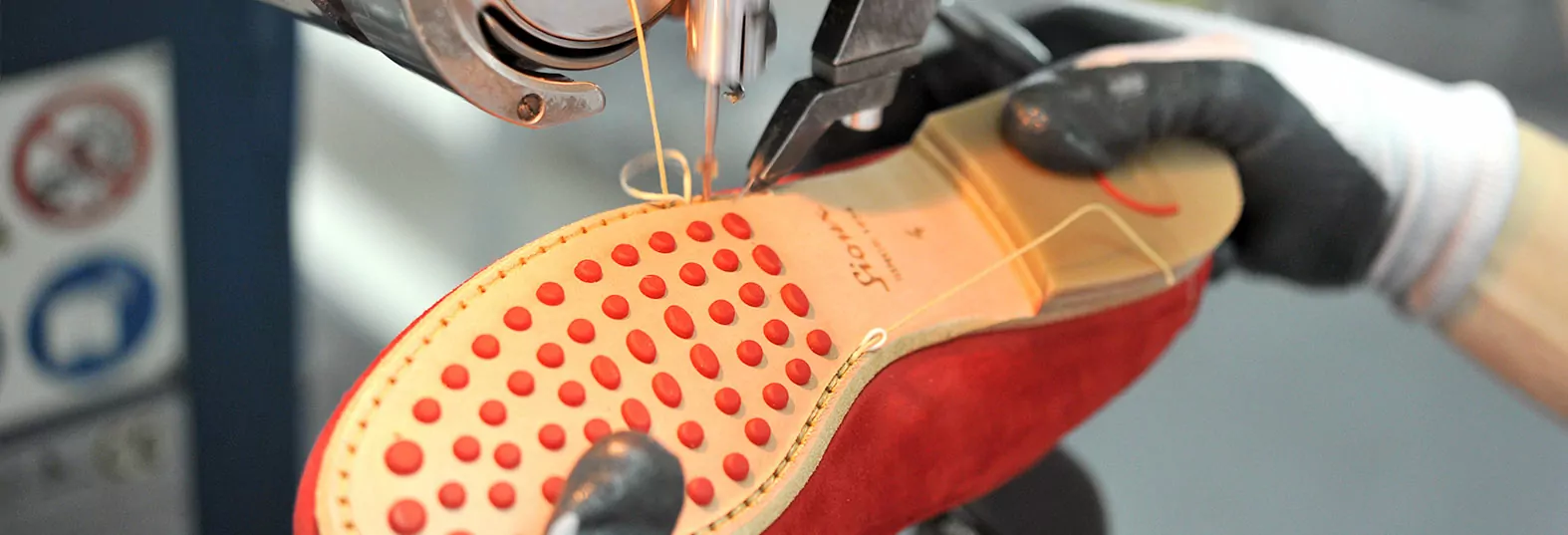

Shoemaking 150 Manufacturing Steps To Make The Perfect Shoe Every shoe is made of two main components, the upper (the shaft) and the base (the sole). a high quality shoe must go through a large number of manufacturing steps until the end product is created. the grashopper alone, for example, consists of 30 individual components and around 150 manufacturing steps. other models vary, depending on the. The sports shoe manufacturing process used to make a kids sneaker, air jordan™, or women’s high heel fashion shoe are very similar. shoe factories around the world follow the basic steps to make a shoe. the basic shoemaking steps are: #1. cutting upper parts. #2. stitching shoe uppers. #3. lasting and assembly.

Shoemaking Process How Shoes Are Made Italian Shoe Factory Lasting techniques: explain the use of lasts to shape the shoe’s final form. 3. finishing touches. trimming and detailing: discuss the final steps involving trimming excess material and adding finishing touches. quality checks: highlight the importance of rigorous quality control in ensuring a flawless product. 4. Step 2: shoe last making. before the shoe manufacturing process starts, the last comes first. a shoe last is the physical base on how your shoes are made. a last is a mould that emulates a foot to give the shoe its shape. these are carved from wood or plastic and every left and right shoe needs one to determine its shape and size. How to cut leather for shoes. shoemaking involves crucial steps, including cutting shoe leather. two methods exist: "copy and then cut" (cc) using scissors after marking with a silver pen, and "cut right away" (cra) using a knife directly on patterns. cra offers precision and professionalism in shoemaking. In shoe making you can use different materials for soles. the easiest way is, to use ready made rubber soles but if you want to learn how to make shoes with natural materials, you always need to use the vegetable tanned leather. for women shoes we use the vegetable tanned leather with a thickness of 2 3.5 mm, for men shoes 4 5 mm.

Shoemaking Process How Shoes Are Made Italian Shoe Factory How to cut leather for shoes. shoemaking involves crucial steps, including cutting shoe leather. two methods exist: "copy and then cut" (cc) using scissors after marking with a silver pen, and "cut right away" (cra) using a knife directly on patterns. cra offers precision and professionalism in shoemaking. In shoe making you can use different materials for soles. the easiest way is, to use ready made rubber soles but if you want to learn how to make shoes with natural materials, you always need to use the vegetable tanned leather. for women shoes we use the vegetable tanned leather with a thickness of 2 3.5 mm, for men shoes 4 5 mm. Learn how to make shoes with our free online course. you study the basics of shoe design and techniques for mass production. get a firm grasp of shoemaking terminology, shoe patterns, and construction. our shoe making tutorials take just a few hours to read. supplement your learning with our shoemaking books, materials, and virtual classes for. 1. design the shoe. 2. develop the shoe. (make the design into a functional shoe.) 3. order the shoe materials. 4. prepare the shoe materials by cutting, printing, and laminating. 5. sew the materials together. 6. last the uppers. 7. assemble the outsoles. 8. pack the shoes. eight easy shoemaking steps! steps one and two can take over a year.

Shoemaking Process How Shoes Are Made Italian Shoe Factory Learn how to make shoes with our free online course. you study the basics of shoe design and techniques for mass production. get a firm grasp of shoemaking terminology, shoe patterns, and construction. our shoe making tutorials take just a few hours to read. supplement your learning with our shoemaking books, materials, and virtual classes for. 1. design the shoe. 2. develop the shoe. (make the design into a functional shoe.) 3. order the shoe materials. 4. prepare the shoe materials by cutting, printing, and laminating. 5. sew the materials together. 6. last the uppers. 7. assemble the outsoles. 8. pack the shoes. eight easy shoemaking steps! steps one and two can take over a year.

Comments are closed.