Screw Air Compressor Working Principle Youtube

Tutorial How To Learn The Working Principle Of Screw Type Air The working principle of a screw compressorscrew air compressor working principlefirst of all, let us take a look at the rotary screw compressor element. the. #engineeringhub #screwcompressorworkingscrew compressor is the precision technology machine to get compressed air. due to its troublefree operation, this typ.

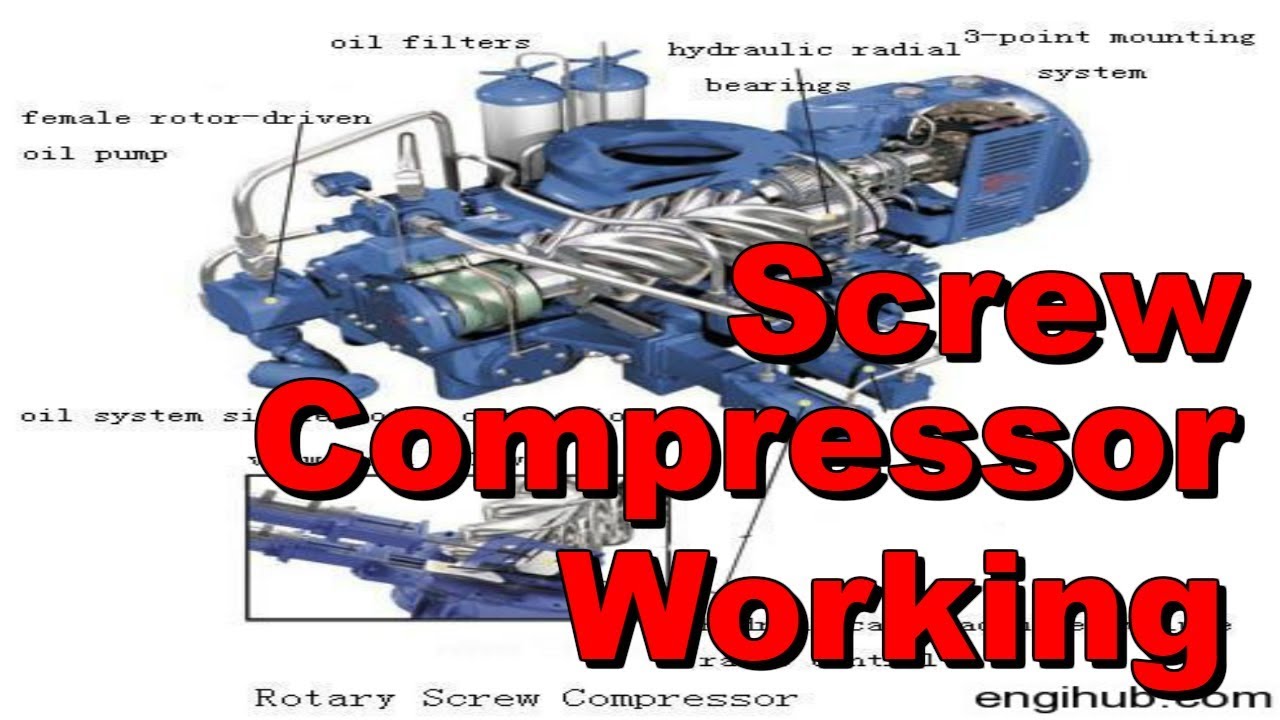

Screw Air Compressor Working Principle Youtube In this video, i'm going to show you how to build a screw air compressor. this is a great project for anyone who wants to learn about how air compressors wor. Screw compressor working principle. a screw compressor works according to the positive displacement mechanism. it uses two spiral rotors (male and female rotors) for the compression of air or gas. these rotors mesh in such a way that the concave cavity of the female rotor meshes with the convex blade of the male rotor. A rotary screw compressor draws air in. the air first travels through a filter, then through an open inlet valve into the compressor element. this inlet valve is effectively a one way valve. when the compressor is turned off, the valve closes, stopping air and oil from heading into the filter. the air is compressed in the compressor element as. A screw compressor works with a male and female rotor that rotate in the opposite direction. this movement draws in air that is compressed as the space between the rotors and their housing decreases. the compressed air is then displaced to the outlet. each screw element has a fixed, built in pressure ratio dependent on the length and pitch of.

Screw Compressor Working Principle Youtube A rotary screw compressor draws air in. the air first travels through a filter, then through an open inlet valve into the compressor element. this inlet valve is effectively a one way valve. when the compressor is turned off, the valve closes, stopping air and oil from heading into the filter. the air is compressed in the compressor element as. A screw compressor works with a male and female rotor that rotate in the opposite direction. this movement draws in air that is compressed as the space between the rotors and their housing decreases. the compressed air is then displaced to the outlet. each screw element has a fixed, built in pressure ratio dependent on the length and pitch of. The screw compressor’s two rotors rotate in opposite directions, they operate on the principle of “screw and lock,” where the male and female rotors interlock to trap and compress air as they rotate. as the rotors rotate, the volume between them decreases, causing the air to be compressed. the compressed air is then discharged through a. A rotary screw air compressor is a type of positive displacement compressor where the compression of air is achieved through the varying volume of intermeshing helical rotors inside the compressor housing. the main and auxiliary rotors rotate within a precision matched housing, creating cyclic changes in the volume between the rotor grooves.

Comments are closed.