Roughing An Epic Punch Reference Material

Roughing An Epic Punch Reference Material Youtube At last a new series! we dive into full traditional animation.it's often said that animating is 50% planning and 50% drawing.it may not be what you expected,. Next we make use of the reference material we made, using it to create roughs of key poses so we can see the very beginnings of the movement taking shape.thi.

Punching Drawing Reference 40 Best Collections Drawing Punch Pose The shift and trace is well hidden feature that makes for a really nice workflow, saving a lot of potential headaches. Sheet metal punching is a fundamental process in precision fabrication, enabling the creation of holes, shapes, and intricate patterns in sheet metal with accuracy and efficiency. from automotive and aerospace to electronics and construction, numerous industries rely on sheet metal punching to produce components and structures with exceptional. Material thickness is the amount the punch must penetrate the workpiece or sheet in making a hole. generally the thicker the material the more difficult it is to punch. material : aluminum brass mild steel stainless shear strength — psi in2(kn mm2): 25000(0.1724) 35000(0.2413) 50000(0.3447) 75000(0.517) material shear strength — material. Most likely for the #321297 181 gr. fn gc for the .32 spl., though tp # 295 for the .32 40 #319295 is the one usually listed for it. these top punches acually have quite a bit of interchangeability, especially in view of lyman's rather "poetic" (to use al's term) approach to nose profiles from cherry to cherry.

Epic Punch Practice Youtube Material thickness is the amount the punch must penetrate the workpiece or sheet in making a hole. generally the thicker the material the more difficult it is to punch. material : aluminum brass mild steel stainless shear strength — psi in2(kn mm2): 25000(0.1724) 35000(0.2413) 50000(0.3447) 75000(0.517) material shear strength — material. Most likely for the #321297 181 gr. fn gc for the .32 spl., though tp # 295 for the .32 40 #319295 is the one usually listed for it. these top punches acually have quite a bit of interchangeability, especially in view of lyman's rather "poetic" (to use al's term) approach to nose profiles from cherry to cherry. Punch and die clearances are usually called out as a percentage of the material thickness being stamped as well as the material type and hardness. these clearances are traditionally called out per side as illustrated in figure 1. the formula for blank and punch clearances is given by. c = (dd dp) 2 (see table 1 for clearances) where:. Work origin should be a consistent point. a reference point that doesn’t change or get carved. if that’s the center work origin, then great. if it’s off to the side or an extra piece of material that works too. there are 3 or 4 settings where heights and work origin are set affected both in setup and toolpaths.

Manga Fight Punch Sketch Anime Poses Reference Manga Drawing Punch and die clearances are usually called out as a percentage of the material thickness being stamped as well as the material type and hardness. these clearances are traditionally called out per side as illustrated in figure 1. the formula for blank and punch clearances is given by. c = (dd dp) 2 (see table 1 for clearances) where:. Work origin should be a consistent point. a reference point that doesn’t change or get carved. if that’s the center work origin, then great. if it’s off to the side or an extra piece of material that works too. there are 3 or 4 settings where heights and work origin are set affected both in setup and toolpaths.

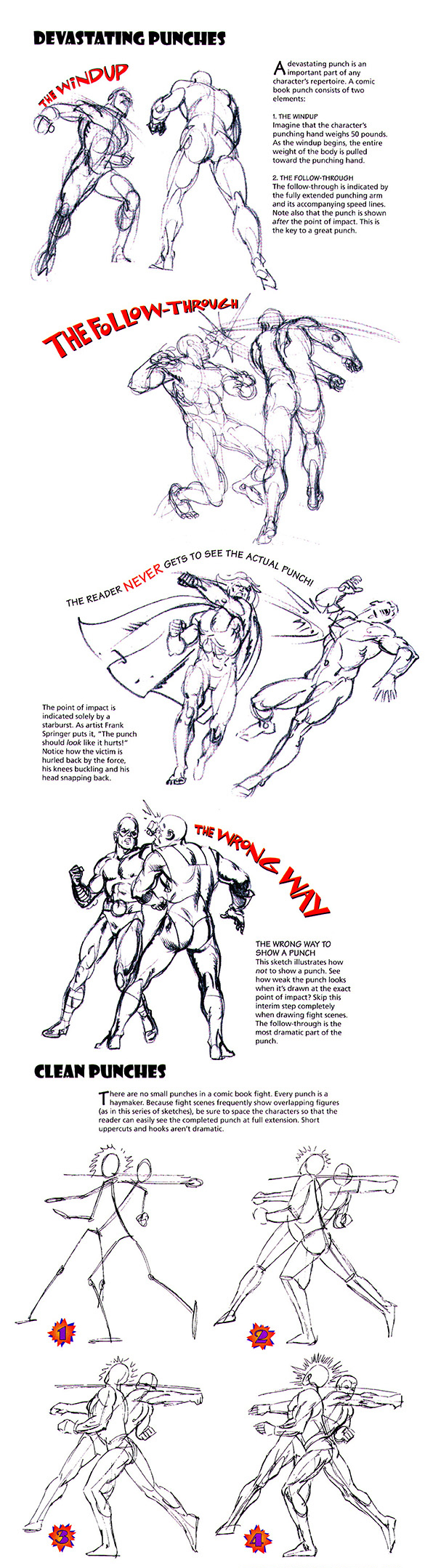

14 Punching Reference Ideas Fighting Poses Art Poses Art Reference

Comments are closed.