Redefining The Automation Strategy In Sheet Metalworking Practical

Redefining The Automation Strategy In Sheet Metalworking Practical Redefining the automation strategy in sheet metalworking february 28, 2019 3:33 pm chicago, il – recently acquired by mitsubishi electric corporation, astes4, a company based in switzerland, specializes in the development of automated sorting solutions for sheet metal laser processing machines. Recently acquired by mitsubishi electric corporation, astes4, a company based in switzerland, specializes in the development of automated sorting solutions for sheet metal laser processing machines. astes4 has developed lasorting – the first fully integrated system for the cutting, sorting, and storage of sheet metal to streamline.

Redefining The Automation Strategy In Sheet Metalworking Mc Machinery Automation and robotics. figure 4. (from left) joe mongeau, president, and ryan mongeau, director of technology, inspect “the claw,” an intricate ceiling bracket formed on the robotic brake. amada america. earlier this year, ryan mongeau inspected an unassuming metal box—16 ga. formed and welded 1008 cold rolled steel, 4 in. tall and deep. Category menu. redefining sheet metal automation strategy. the astes4 lasorting system from mc machinery is a fully integrated system for cutting, sorting and storage of sheet metal to streamline processes, speed up production and reduce labor costs. for automated cutting, sorting and storage of sheet metal, the fully integrated astes4. The goal is automation in the thick sheet metal sector one of the two lissmac lines will already be used in automated production. steel sheets up to 40mm thick will be processed here. the second system will be used to process sheets up to 100mm thick. automation is planned here as well. In 2024, the metalworking and machine shop landscape will witness a profound shift, with artificial intelligence (ai) and machine learning (ml) emerging as critical trends. ai driven product design tools are becoming integral to the industry, as they facilitate the creation of intricate and precise components. meanwhile, ml algorithms are adept.

High Automation Rate For High Efficiency Sheet Metal Working Metal The goal is automation in the thick sheet metal sector one of the two lissmac lines will already be used in automated production. steel sheets up to 40mm thick will be processed here. the second system will be used to process sheets up to 100mm thick. automation is planned here as well. In 2024, the metalworking and machine shop landscape will witness a profound shift, with artificial intelligence (ai) and machine learning (ml) emerging as critical trends. ai driven product design tools are becoming integral to the industry, as they facilitate the creation of intricate and precise components. meanwhile, ml algorithms are adept. Automation and robotics allow sheet metal forming manufacturers to scale up or down depending on your current demand. with the right automation and robotics in the mix, you can quickly scale your production programs without increasing labor, helping you go from prototype to production quickly. speed. production speed can be improved with. Automated metal processing is also an excellent option for reducing strain. if workers’ roles require loading or unloading large pieces of sheet metal as it goes through various stages, partial or complete automation can save people from manually handling those components. 4. become a data driven company.

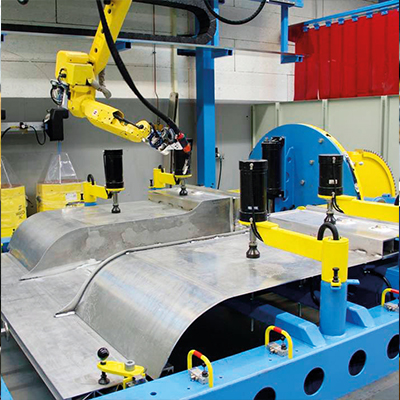

Automate Sheet Metal Production Fanuc Automation and robotics allow sheet metal forming manufacturers to scale up or down depending on your current demand. with the right automation and robotics in the mix, you can quickly scale your production programs without increasing labor, helping you go from prototype to production quickly. speed. production speed can be improved with. Automated metal processing is also an excellent option for reducing strain. if workers’ roles require loading or unloading large pieces of sheet metal as it goes through various stages, partial or complete automation can save people from manually handling those components. 4. become a data driven company.

Automating The Sheet Metal Process

Robot Automation Increases Flexibility In Sheet Metal Fabrication Lines

Comments are closed.