Redefining The Automation Strategy In Sheet Metalworking Mc Machinery

Redefining The Automation Strategy In Sheet Metalworking Mc Machinery Redefining the automation strategy in sheet metalworking published on: march 5th, 2019 recently acquired by mitsubishi electric corporation, astes4, a company based in switzerland, specializes in the development of automated sorting solutions for sheet metal laser processing machines. Category menu. redefining sheet metal automation strategy. the astes4 lasorting system from mc machinery is a fully integrated system for cutting, sorting and storage of sheet metal to streamline processes, speed up production and reduce labor costs. for automated cutting, sorting and storage of sheet metal, the fully integrated astes4.

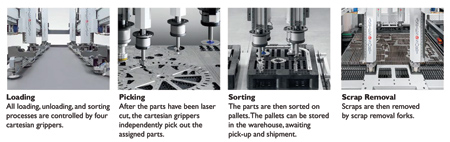

Redefining The Automation Strategy In Sheet Metalworking Practical Astes4 sort. with a fully integrated system for laser cutting, sorting, and storing sheet metal, the astes4 is your all in one solution for laser automation. capable of controlling the entire production process—from loading, cutting, sorting, and unloading through to the storage of the finished parts—the astes4 sort is the process. By mc machinery senior laser applications manager michael koch doing more with less is the name of the game in laser cutting—and will be for the foreseeable future. with an ongoing labor shortage, fluctuating metal prices, increasing demand and smaller profit margins, technology is advancing rapidly to help fabricators succeed amidst these. Sheet metal automation allows for quick changeovers between part numbers — something that is particularly helpful depending on your mix of products. machines with automatic tool changeovers cut set up times to almost 0, a process that can takes hours depending on part complexity. additionally, engineering changes are quicker because you only. October 23, 2024. news release. automation and software. mc machinery systems has entered into an exclusive partnership with acieta to offer the fastbend robotic bending cell. the cell, which combines acieta’s robot with mc machinery’s diamond bb series electric press brake, is designed to help fabricators eliminate bottlenecks in.

Fully Integrated System For Sheet Metal Operations Sheet metal automation allows for quick changeovers between part numbers — something that is particularly helpful depending on your mix of products. machines with automatic tool changeovers cut set up times to almost 0, a process that can takes hours depending on part complexity. additionally, engineering changes are quicker because you only. October 23, 2024. news release. automation and software. mc machinery systems has entered into an exclusive partnership with acieta to offer the fastbend robotic bending cell. the cell, which combines acieta’s robot with mc machinery’s diamond bb series electric press brake, is designed to help fabricators eliminate bottlenecks in. While imported automation equipment may not be user friendly, the cheapest option may also not be the most user friendly. sheet metal enterprises should select automation equipment based on their own product characteristics, which adds value. author. learn how to choose the right equipment for automated sheet metal fabrication. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. this precision driven process transforms flat metal sheets into intricate components. over the decades, sheet metal manufacturing has evolved from manual.

Comments are closed.