Rack Inspection Checklists Explained

Free Rack Inspection Checklist Download Here Generate reports from completed checklists. free to use for up to 10 users. start using template. a racking inspection checklist aims to identify exactly which components of warehouse racks are damaged using the traffic light system. instantly assign corrective actions to address health and safety risks with the use of this checklist. One of our most useful services is a basic introduction to racking inspections. our infographic should serve as a starting point for businesses who want their staff to learn more about racking inspections and how racking inspection checklists work. it’s a great graphic to print out and put around your workplace. and it’s yours for free!.

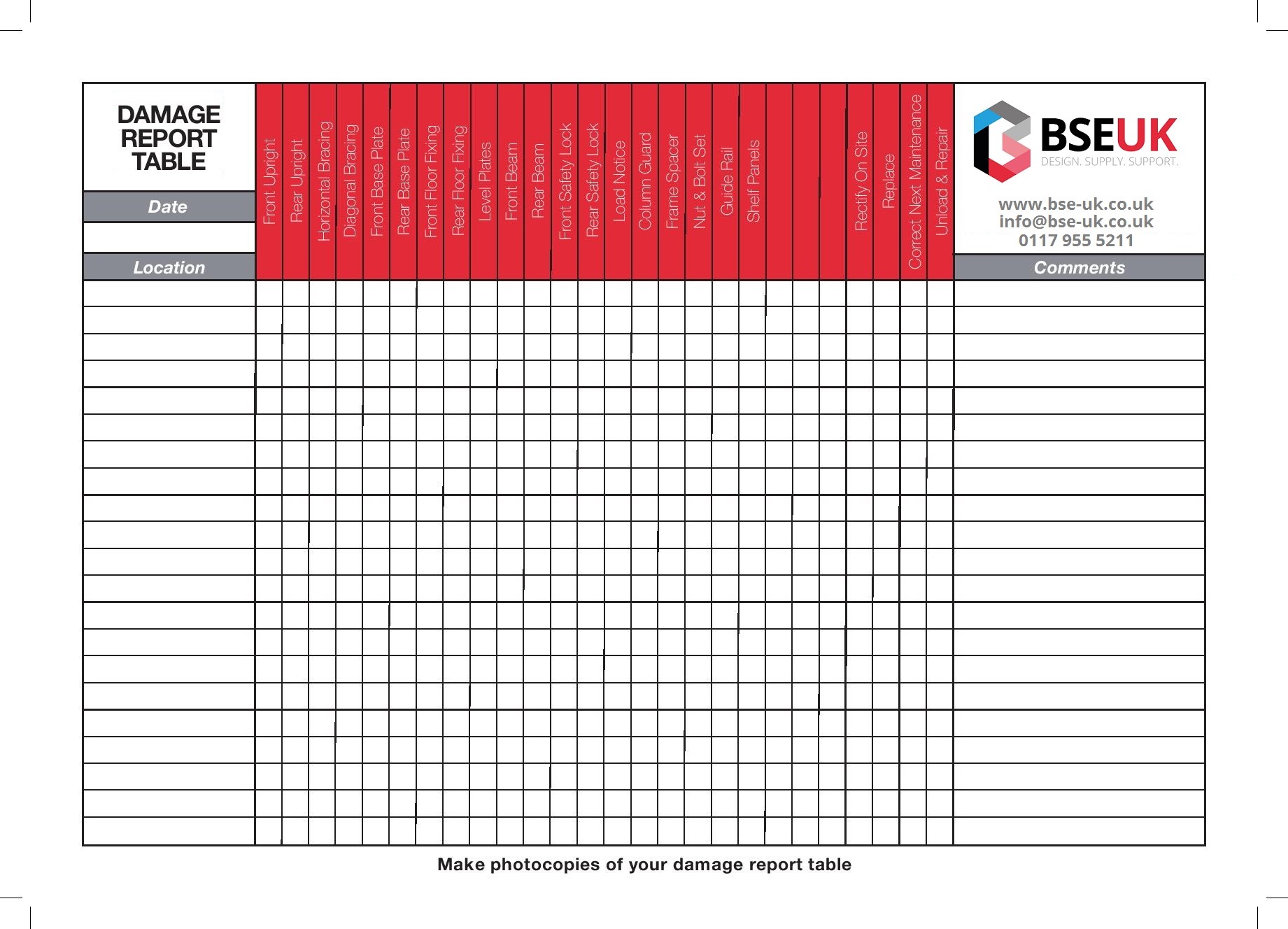

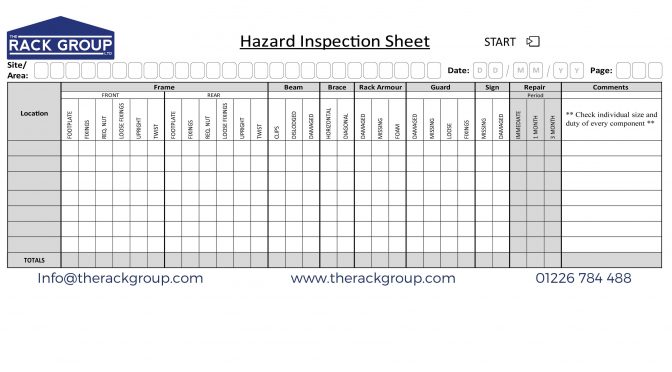

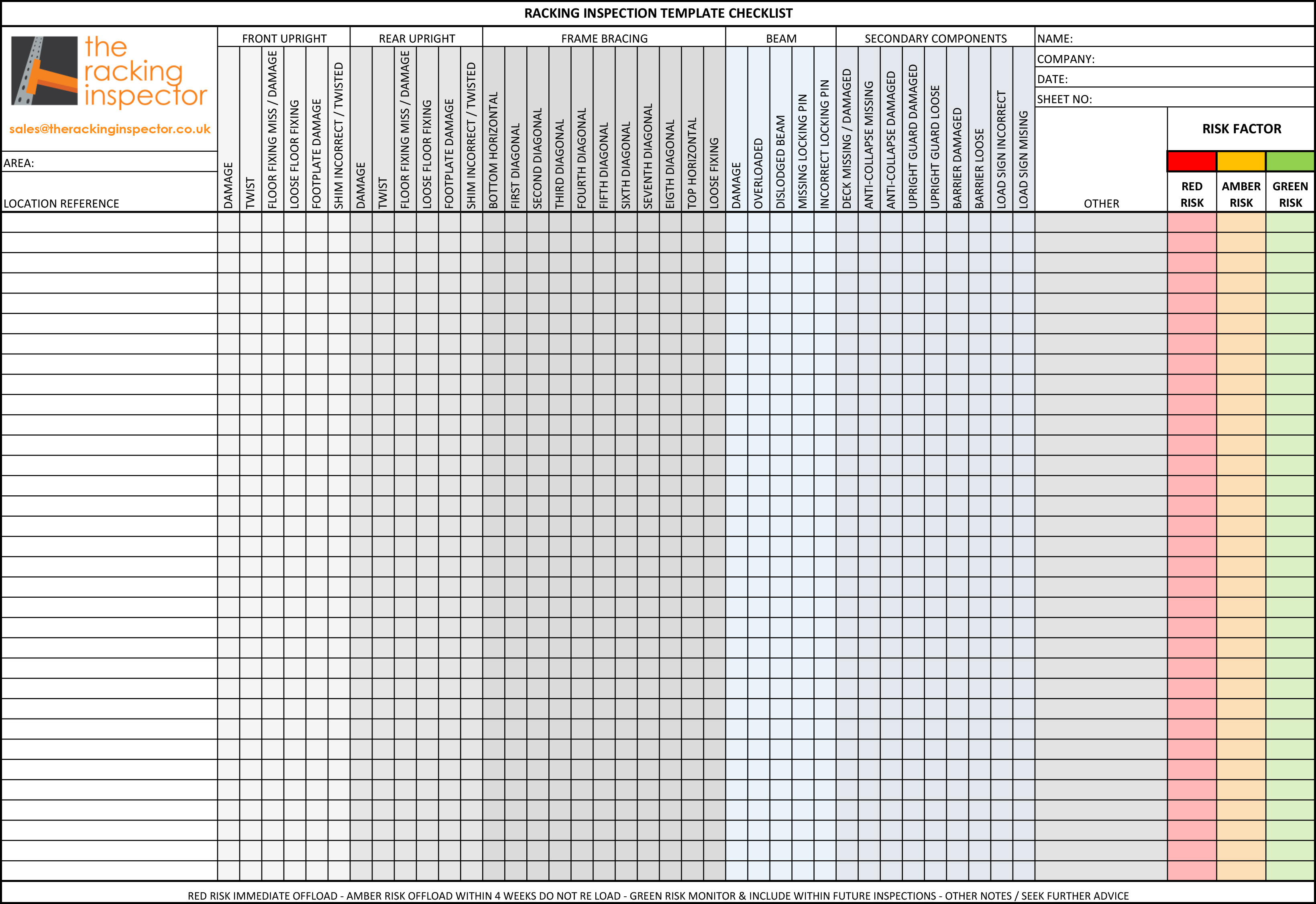

Racking Inspection Checklist Rack Inspection Rack inspections: an overview. rmiwriter. august 20, 2019. among the many best practices to ensure the safety of industrial steel storage rack systems and the workers around it, inspections are among the most critical. indeed, there are several kinds of rack inspections, including: inspections required by building codes: the international code. Here’s your step by step guide to pallet rack inspections. clear the aisles: remove any obstructions to ensure clear access to the pallet racking systems. start from the top: begin the inspection at the highest point of the pallet racks and work your way down. meticulous examination: thoroughly inspect each component of the racking system. The importance of racking inspections cannot be overstated. inadequate racking management can lead to structural failures, safety hazards, and disruptions in your warehouse operations. these checklists are designed to help you conduct thorough inspections, identify potential issues, and implement corrective measures promptly. by leveraging. A proper racking inspection checklist will review all components of the storage system: uprights: check for damage, dents or rust and ensure they are securely bolted to the floor and not twisted. beams: look for bends, cracks or broken welds and confirm beam connectors and beam to upright connections are secure.

Free Rack Inspection Checklist Download Sema Approved The importance of racking inspections cannot be overstated. inadequate racking management can lead to structural failures, safety hazards, and disruptions in your warehouse operations. these checklists are designed to help you conduct thorough inspections, identify potential issues, and implement corrective measures promptly. by leveraging. A proper racking inspection checklist will review all components of the storage system: uprights: check for damage, dents or rust and ensure they are securely bolted to the floor and not twisted. beams: look for bends, cracks or broken welds and confirm beam connectors and beam to upright connections are secure. A racking inspection checklist form is a tool used by internal staff as well as by certified auditors to assess the potential safety risks in warehouse storage racks. the pallet racking checklist template helps cover all the elements of the racks, such as beams, frames, and braces, and determine the level of risks using traffic light systems. Experienced permit expediters can play an essential role in helping you pass racking inspections on the first go. when you partner with the right expediter who has in depth local knowledge and experience, you receive help in obtaining all necessary permits for a racking installation or update and the expertise required to keep apprised of any changes in local codes and regulations prior to.

Storage Rack Inspection Checklist Format Excel Pdf Sample A racking inspection checklist form is a tool used by internal staff as well as by certified auditors to assess the potential safety risks in warehouse storage racks. the pallet racking checklist template helps cover all the elements of the racks, such as beams, frames, and braces, and determine the level of risks using traffic light systems. Experienced permit expediters can play an essential role in helping you pass racking inspections on the first go. when you partner with the right expediter who has in depth local knowledge and experience, you receive help in obtaining all necessary permits for a racking installation or update and the expertise required to keep apprised of any changes in local codes and regulations prior to.

Comments are closed.