Pressure Gauge Exploded View Electrical Blog

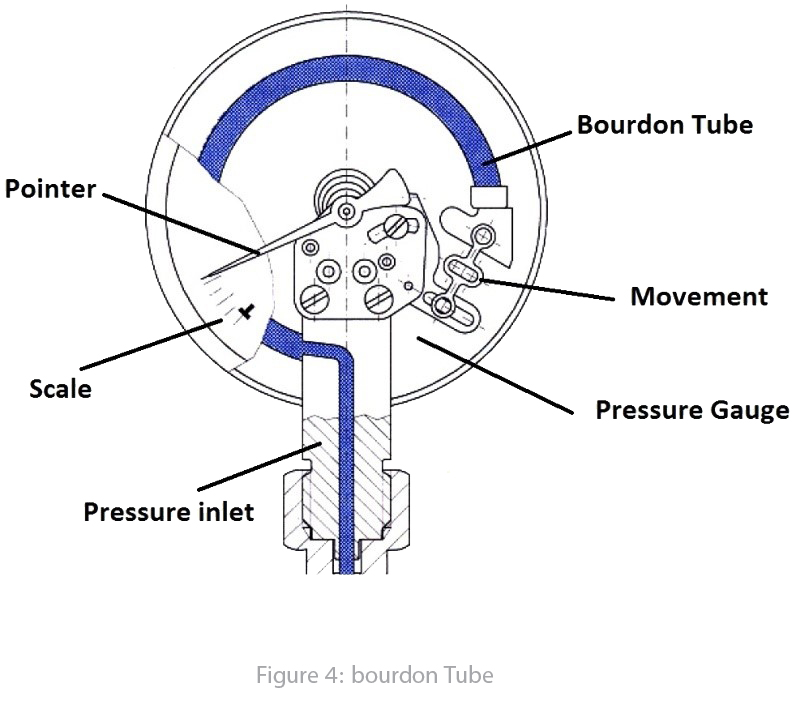

Pressure Gauge Exploded View Electrical Blog Electrical engineering world is the worldwide community with members engaged in the electrical power industry. mission energy & power for all! mission our mission is to be the leading provider of scientific information on education, power and electricity in general. we write, we share and spread knowledge. Bourdon tube pressure gauges are the most frequently used mechanical pressure measuring instruments. their pressure element is often referred to as a bourdon tube: the french engineer eugène bourdon made use of this functional principle in the middle of the 19th century. it is based on an elastic spring, a c shaped, bent tube with an oval.

Instrumentation Basics Pressure Gauge Basics A bourdon tube pressure gauge is attached to the pipeline at the inlet pipe (d). the socket block (g) holds the inlet pipe in place, which also holds the device to the process line. fluid flows into the stationary end of the bourdon tube (c). the fluid pressure distributes throughout the c shaped bourdon tube (e). Assembly and operating instructions for pressure gauges 09 22 ・p. 3 of 14 3. device description 3.1 types of pressure gauges bourdon tube pressure gauge diaphragm pressure gauge 3.2 exploded view drawing of pressure gauge with solid front case, blow out back (acc. din en 837 1, s3). A pressure gauge is an instrument for measuring fluid intensity in a pressure powered machine. this fluid intensity is specified by the force that the fluid would exert on a specific unit area. typical pressure gauge intensity measurement units are pounds per square inch ( psi ), or newtons per square meter called the pascal . Ashcroft ® pressure gauges are supplied in a wide variety of sizes, accuracies and ranges from 0 – 10 in. h 2 o through 0 100,000 psi. choices include differential pressure gauges, test gauges, sanitary gauges, high purity gauges, subsea gauges, digital pressure gauges, oem pressure gauges and more. known for high quality and reliability.

Pressure Gauge Parts Hs Code At John Candler Blog A pressure gauge is an instrument for measuring fluid intensity in a pressure powered machine. this fluid intensity is specified by the force that the fluid would exert on a specific unit area. typical pressure gauge intensity measurement units are pounds per square inch ( psi ), or newtons per square meter called the pascal . Ashcroft ® pressure gauges are supplied in a wide variety of sizes, accuracies and ranges from 0 – 10 in. h 2 o through 0 100,000 psi. choices include differential pressure gauges, test gauges, sanitary gauges, high purity gauges, subsea gauges, digital pressure gauges, oem pressure gauges and more. known for high quality and reliability. The system may look complicated, but it’s really quite simple. let‘s take the model 213.40 bourdon tube pressure gauge as an example. a. instrument series or type. 1 = standard (100 series): general purpose, low cost. 2 = industrial (200 series): high quality. 3 = test gauge: high precision. 4 = sealgauge™: diaphragm gauge. A pressure gauge is a measuring instrument used to measure the pressure or pressure level in fluids (liquid or gas). pressure gauges are important for setting up and directing or regulating the fluid power equipment, as well as troubleshooting them. fluid power systems would be erratic and unreliable without pressure gauges.

Pressure Gauge Exploded View Mechanicstips Free Word Template The system may look complicated, but it’s really quite simple. let‘s take the model 213.40 bourdon tube pressure gauge as an example. a. instrument series or type. 1 = standard (100 series): general purpose, low cost. 2 = industrial (200 series): high quality. 3 = test gauge: high precision. 4 = sealgauge™: diaphragm gauge. A pressure gauge is a measuring instrument used to measure the pressure or pressure level in fluids (liquid or gas). pressure gauges are important for setting up and directing or regulating the fluid power equipment, as well as troubleshooting them. fluid power systems would be erratic and unreliable without pressure gauges.

Comments are closed.