Ppt Technical Details Of Pvc Pressure Fittings Powerpoint

Ppt Technical Details Of Pvc Pressure Fittings Powerpoint This document has been developed by the uni bell pvc pipe association for design and installation of gasketed pvc fittings where gasketed pvc pressure pipe is used in potable water, force main, pressure irrigation, and reclaimed water applications.the guide provides information on gasketed pvc fittings that are available for various dimension ratios and outside diameters of pvc pipe through 60. Technical details of pvc pressure fittings an image link below is provided (as is) to download presentation download policy: content on the website is provided to you as is for your information and personal use and may not be sold licensed shared on other websites without getting consent from its author.

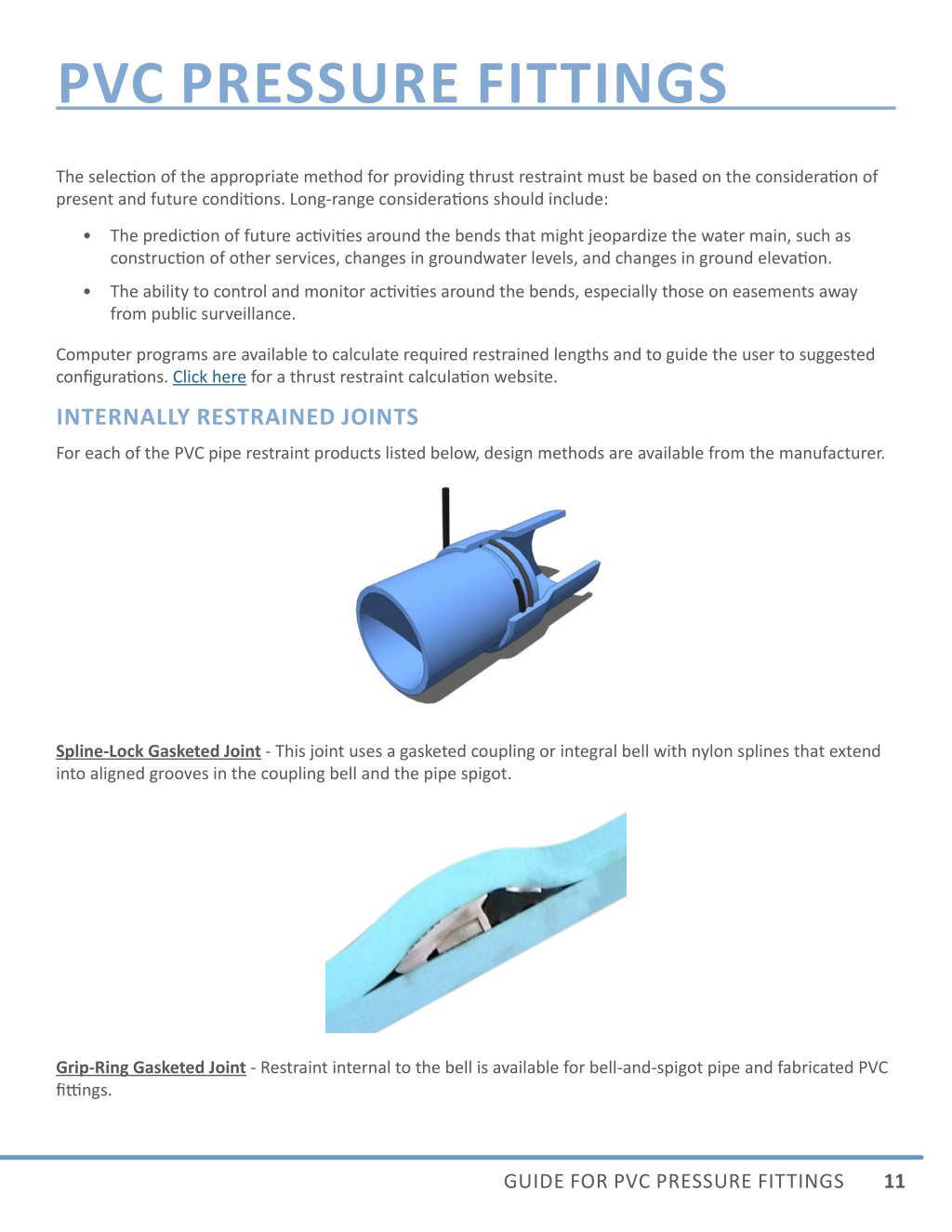

Ppt Guide For Pvc Pressure Fittings Powerpoint Presentation Free Guide for pvc pressure fittings. fabricated pvc fittings are available for any size pvc pipe from 4 inch through 60 inch. fabricated fittings are available in multiple pressure classes and have the same or greater pressure class as the pvc pipe to which they are joined. please use awwa c900 for fabricated fittings recommended specifications. This document has been developed by the uni bell pvc pipe association for design and installation of gasketed pvc fittings where gasketed pvc pressure pipe is used in potable water, force main, pressure irrigation, and reclaimed water applications.the guide provides information on gasketed pvc fittings that are available for various dimension. This document has been developed by the uni bell pvc pipe association for design and installation of pvc fittings where solid wall pvc pipe is used in non pressure applications. the guide provides information on the wide range of fittings that are available for various dimension ratios and outside diameters of pvc pipe through 60 inch. It is recommended not to build any pvc installation in the outside because of the material’s low resistance to sunlight. the protection of the pvc piping can be ensured by using special uv resistant paints or by just burying the whole insallation. standards : glued pvc fittings: en 1452 3 standard. pvc pipes en 1452 2 standard.

Ppt Technical Details Of Pvc Pressure Fittings Powerpoint This document has been developed by the uni bell pvc pipe association for design and installation of pvc fittings where solid wall pvc pipe is used in non pressure applications. the guide provides information on the wide range of fittings that are available for various dimension ratios and outside diameters of pvc pipe through 60 inch. It is recommended not to build any pvc installation in the outside because of the material’s low resistance to sunlight. the protection of the pvc piping can be ensured by using special uv resistant paints or by just burying the whole insallation. standards : glued pvc fittings: en 1452 3 standard. pvc pipes en 1452 2 standard. 4 | pvc pressure fittings – technical specifications catalogue upvc pressure fitting as nzs1477 side outlet elbow code size dn end* d1 d2 l1 l3 weight kg 802 20 15 3 4”x1 2” 20x15 sxt 32.10 25.80 48.95 26.80 0.028 802 25 15 1”x1 2” 25x15 sxt 39.60 25.80 58.80 30.20 0.045 material: 1. body upvc *sxt = socket glued x small female. E and jam taps and valves.step 2 – check alignmentcheck and ensure. the pipe and spigot or fittings are properly aligned. adjustments or alterations must be made prior to applying the solvent cement. romised at the welding stage.step 3 – mark clearlymark the spigot by using a pencil or marker only, at a di.

Ppt High Pressure Pipe Fittings Instrumentation Tube Fittings 4 | pvc pressure fittings – technical specifications catalogue upvc pressure fitting as nzs1477 side outlet elbow code size dn end* d1 d2 l1 l3 weight kg 802 20 15 3 4”x1 2” 20x15 sxt 32.10 25.80 48.95 26.80 0.028 802 25 15 1”x1 2” 25x15 sxt 39.60 25.80 58.80 30.20 0.045 material: 1. body upvc *sxt = socket glued x small female. E and jam taps and valves.step 2 – check alignmentcheck and ensure. the pipe and spigot or fittings are properly aligned. adjustments or alterations must be made prior to applying the solvent cement. romised at the welding stage.step 3 – mark clearlymark the spigot by using a pencil or marker only, at a di.

Comments are closed.