Powerplant Generator Cooling System

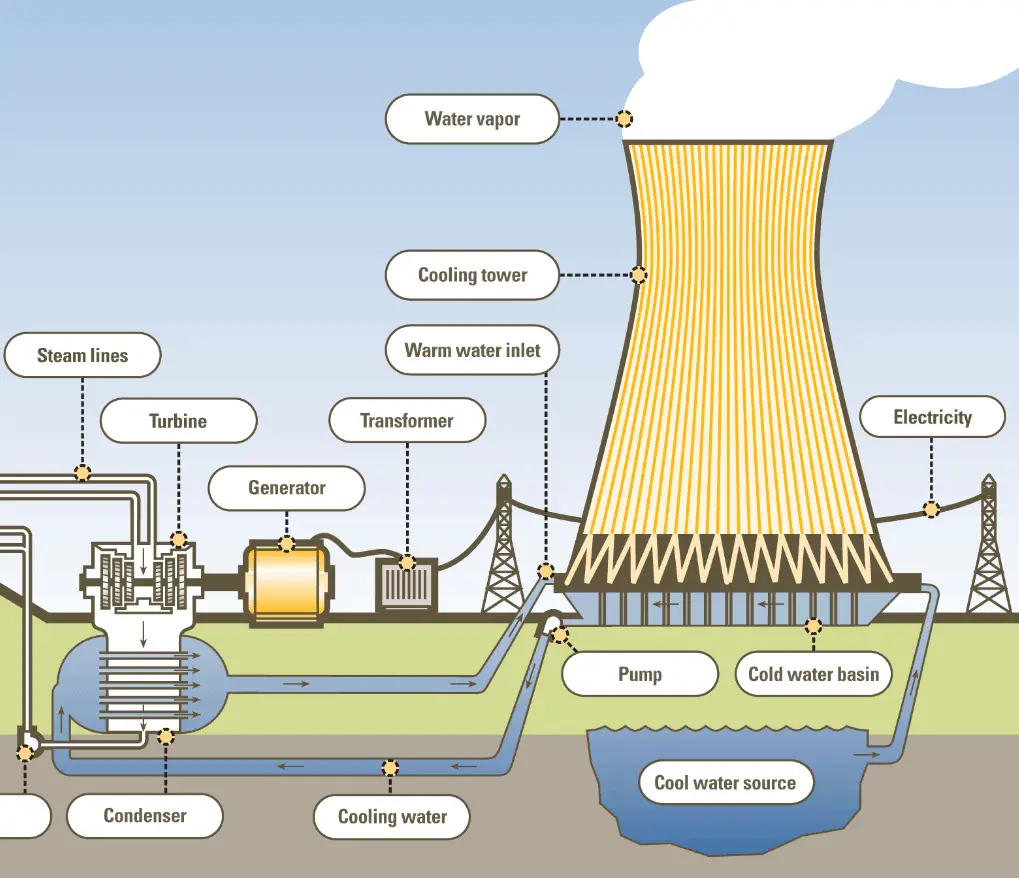

What Are The Different Generator Cooling System In Power Plants The generator in the power plant are designed for continuous operation. thus, the cooling system plays an important role in order to keep it's reliability. generators used in power generation applications can be placed in three major design classifications based on the cooling medium used: air; hydrogen; water. An ethylene glycol based coolant is circulated through the cooling system components. three common cooling system configurations are: single pump single loop (spsl) – spsl systems are common in smaller to mid size generator applications. operation for this system as follows: • engine starts, direct drive pump is driven and fan clutch is.

What Are The Different Generator Cooling System In Power Plants Epri’s preliminary first order estimates show that cooling innovations resulting in a 15°c reduction of the steam condensing temperature, from 50°c to 35°c, would result in 5% more power production. at an electricity price of $0.05 kwh, this is equivalent to $11m more annual revenue for a 500 mw power plant. These cutting edge heat exchangers are designed to optimize the cooling process, ensuring optimal performance and longevity of generators. they work by efficiently transferring heat from the engine coolant, intercooler, and oil cooler, improving overall cooling efficiency. in the world of power generation, efficient cooling with heat exchangers. Initial purchase price: liquid cooled generators can cost approximately 50% to 100% more than air cooled generators. for example, if an air cooled generator costs $3,000, a comparable liquid cooled generator might cost $4,500 to $6,000. installation costs: installation for liquid cooled generators tends to be about 30% to 50% higher due to the. Steam generators. the reactor coolant flows from the reactor to the steam generator. inside of the steam generator, the hot reactor coolant flows inside of the many tubes. the secondary coolant, or feedwater, flows around the outside of the tubes, where it picks up heat from the primary coolant.

Animated Overview Of Industrial Generator Cooling System Youtube Initial purchase price: liquid cooled generators can cost approximately 50% to 100% more than air cooled generators. for example, if an air cooled generator costs $3,000, a comparable liquid cooled generator might cost $4,500 to $6,000. installation costs: installation for liquid cooled generators tends to be about 30% to 50% higher due to the. Steam generators. the reactor coolant flows from the reactor to the steam generator. inside of the steam generator, the hot reactor coolant flows inside of the many tubes. the secondary coolant, or feedwater, flows around the outside of the tubes, where it picks up heat from the primary coolant. %pdf 1.6 %âãÏÓ 333 0 obj > endobj 361 0 obj > encrypt 334 0 r filter flatedecode id[6d0abf1dbda149d5a69a914573c3b02a>] index[333 48] info 332 0 r length 119 prev. This variable should be adjusted to maintain the required flow rate while keeping surge pressure below 1.5 times the piping material’s maximum working pressure. linear fluid flow velocity within the piping system should generally be limited to 5 ft s for power generation plants, especially for pipes six inches or larger.

Cooling System Circulating Water System Nuclear Power %pdf 1.6 %âãÏÓ 333 0 obj > endobj 361 0 obj > encrypt 334 0 r filter flatedecode id[6d0abf1dbda149d5a69a914573c3b02a>] index[333 48] info 332 0 r length 119 prev. This variable should be adjusted to maintain the required flow rate while keeping surge pressure below 1.5 times the piping material’s maximum working pressure. linear fluid flow velocity within the piping system should generally be limited to 5 ft s for power generation plants, especially for pipes six inches or larger.

What Are The Different Generator Cooling System In Power Plants

Comments are closed.