Piping Pipe Classification Pipe Schedule

Ansi Pipe Schedules How To Use A Pipe Schedule Chart Nominal pipe size (nps) is the number that defines the size of the pipe. for example, when you say 6” pipe, the 6” is the nominal size of that pipe. however, for the pipe sizes, nps 14 and above outside diameter is the same as nps. to understand this concept, you have to learn the way pipes are manufactured. manufacturing of nps ⅛ (dn 6. "gripsafe plugs have been valuable assets on the lngc site. the quick and easy installation, use, and removal of the plugs have made testing plain end pipe simple. the lifting device makes rigging of the larger plugs into position fast, convenient, and safe. the design of the grippers leave little to no marks inside the pipe.

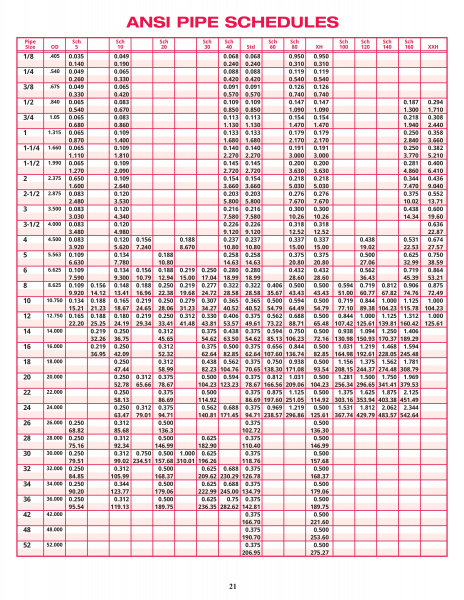

Thomas Services Pipe Classifications Obviously, for pipes containing pressurised fluids the wall thickness, and by implication the pipe’s strength, is important. wall thickness is expressed in “ schedules “, referred to as pipe schedules. the pipe schedule is abbreviated as sch. for a given size and schedule the thickness of the pipe is fixed and defined in the applicable. Pipe schedule numbers can be the same for different pipe sizes but that does not mean the pipe thickness is the same. it may be the same or vary with respect to pipe sizes. for example, a 6 inch schedule 40 pipe has 7.11 mm thickness, while an 8 inch schedule 40 pipe has 8.18 mm thickness means thickness is increasing even though both schedule 40. Velocity and flow capacity of oil schedule 160 pipe. steel pipe flow friction loss for sizes 10" to 12 " inch diameter. friction losses in steel pipes size 0.5 to 1.25 inch diameter. friction loss in steel pipe 1.5" to 3" inch diameter. steel pipe flow loss friction for sizes 4 " to 8 " inch diameter. You would: look up 2 inch pipes in the pipe schedule chart. review the wall thickness and inside diameter for various schedules (e.g., schedule 40, 80, or 160). based on the high pressure requirement, select schedule 80, which offers a thicker wall (0.218 inches) compared to schedule 40 (0.154 inches).

Sch 40 Pipe Dimensions Weight Wall Thickness Standard Specifications Velocity and flow capacity of oil schedule 160 pipe. steel pipe flow friction loss for sizes 10" to 12 " inch diameter. friction losses in steel pipes size 0.5 to 1.25 inch diameter. friction loss in steel pipe 1.5" to 3" inch diameter. steel pipe flow loss friction for sizes 4 " to 8 " inch diameter. You would: look up 2 inch pipes in the pipe schedule chart. review the wall thickness and inside diameter for various schedules (e.g., schedule 40, 80, or 160). based on the high pressure requirement, select schedule 80, which offers a thicker wall (0.218 inches) compared to schedule 40 (0.154 inches). Using the pipe schedule chart above, find the corresponding thickness in the horizontal row. identify the ansi pipe schedule value. for example, let’s say your steel pipe od is 3.5” and the thickness is 0.216”. by locating these values on the above chart, you will find that you have an ansi schedule 40 steel pipe. A pipe schedule chart is a detailed reference that provides the specifications of the wall thickness, outer diameter (od), and sometimes the inner diameter (id) for various sizes of pipes. the “schedule” part of the name refers to the wall thickness of the pipes. each schedule number corresponds to a specific wall thickness, which is.

Comments are closed.