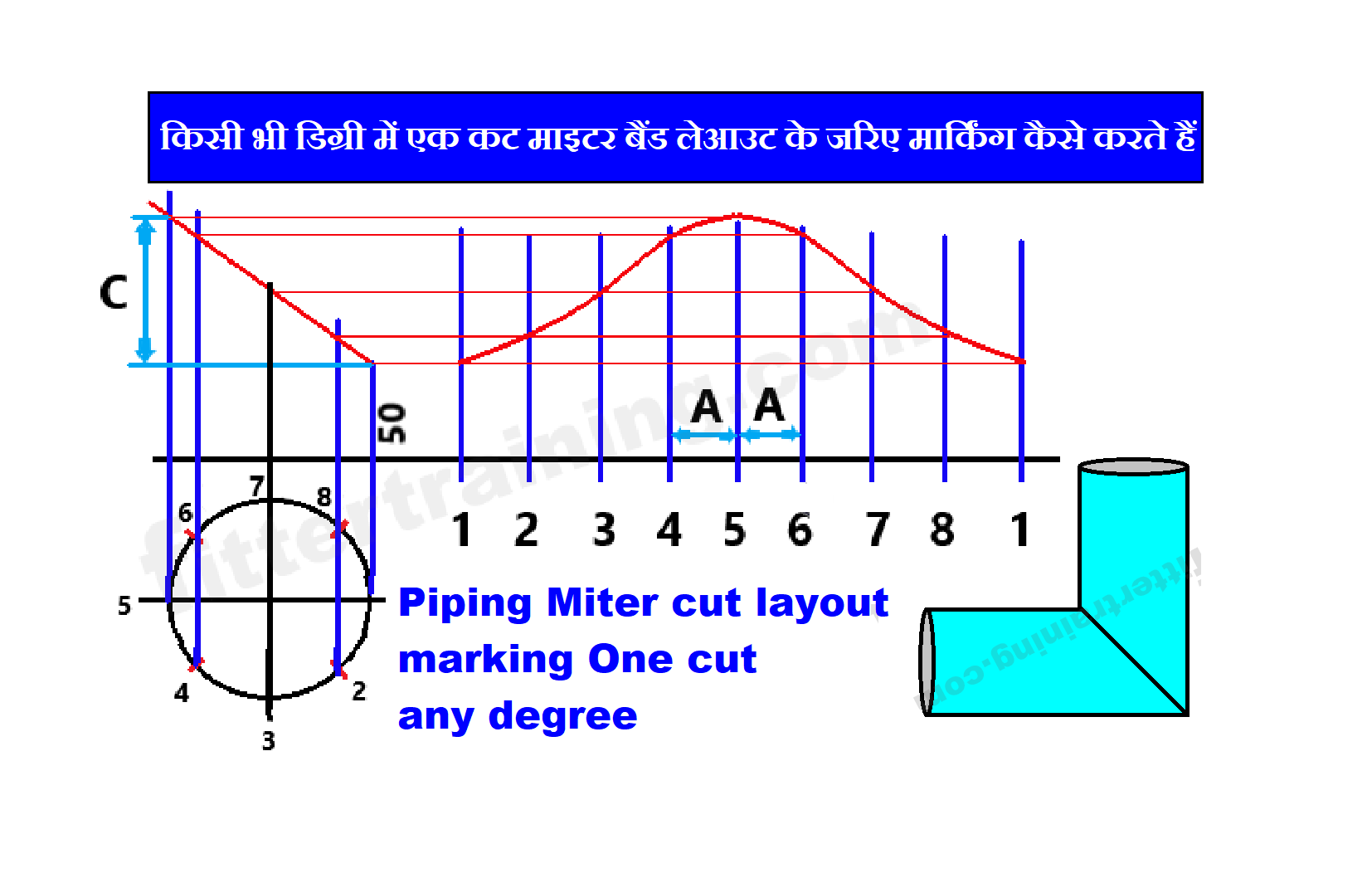

Piping Miter Cut Layout Marking One Cut Any Degree Pipe Miter Cut

Piping Miter Cut Layout Marking One Cut Any Degree Pipe Miter Cut How to layout a single cut miter bend. pipe bend. tutorial for beginners @technicalstudies.donate paypal.me technicalstudies502#piping #technique #we. A miter bend or miter elbow is prepared by mitering (angle cutting) and welding pipe ends of the cut pieces, usually at 45° and 90° to form a corner. there are two types of miter bend, one non perpendicular bend & another is 3 d bend. miter elbow bend is made from miter cut pieces of pipe. the miter pieces also called gores, there are two end.

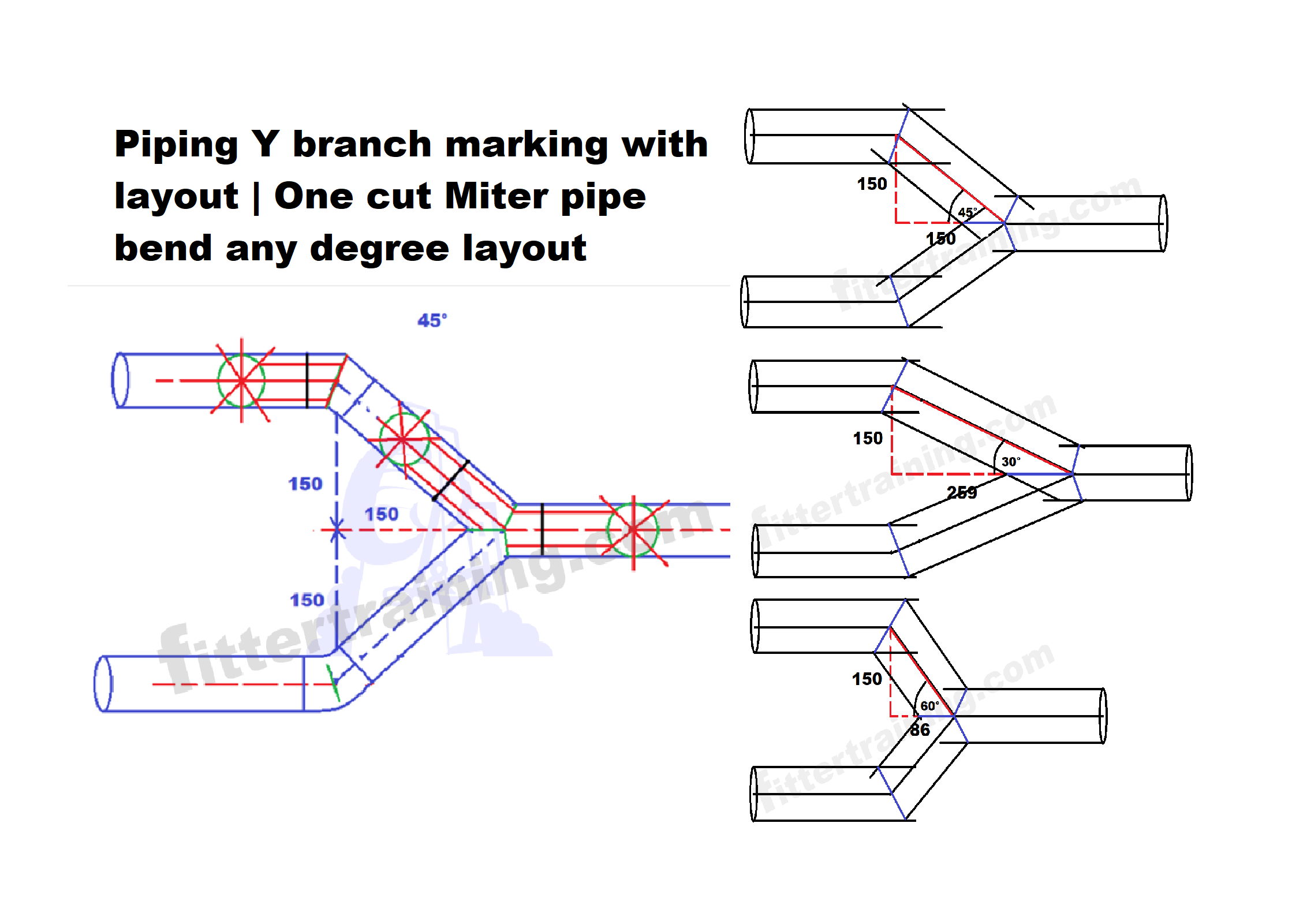

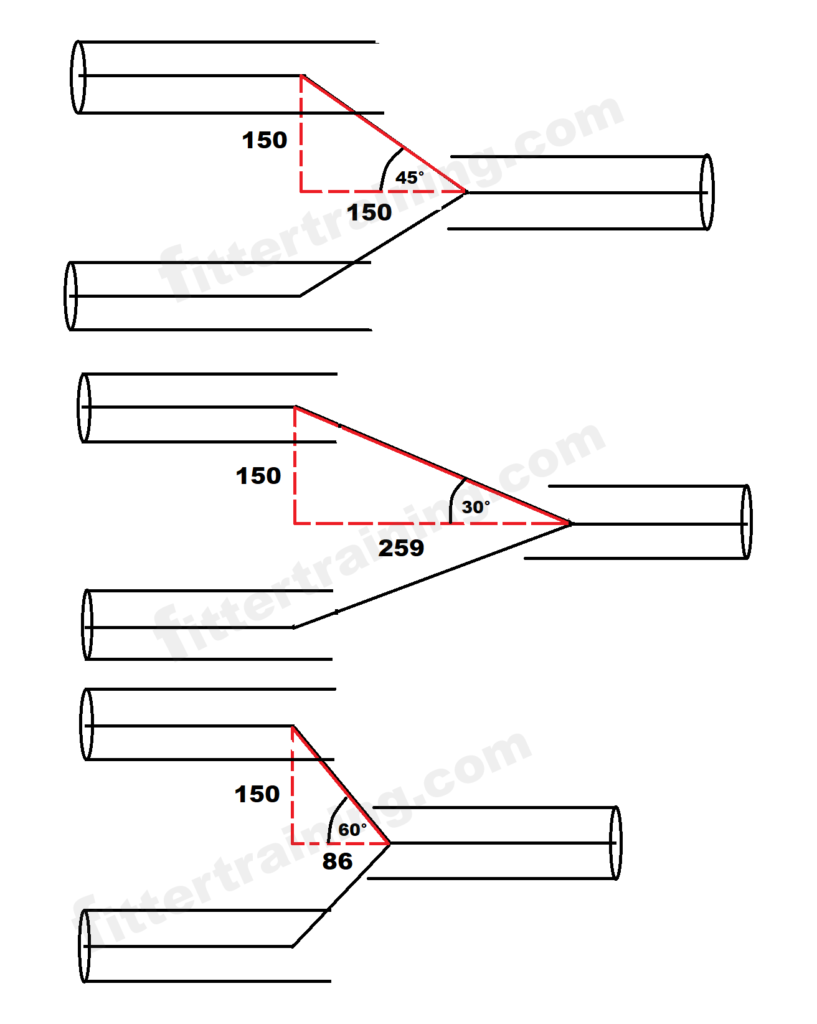

Piping Y Branch Marking With Layout One Cut Miter Pipe Bend Any How to calculate 51 mm. tan ( degree ÷ 2 ) × pipe od answer ÷ 2 = cut back. use only vertical degree miter cut off tow. tan ( 41÷2 ) × 273 ÷ 2 = 51 mm. tow miter cut seam degree. spread the love. pipe branch hole marking pdf chart | 8″× 8″ to 8″ × 34″. pipe fitter interview questions and answers. Pipe offset calculation. how to calcylate single cut miter pipe offset formula, calculations, and markingplease share the videos with your friends. piping, p. θ = angle of the miter cut r 2 = mean radius of the pipe = (d t) 2 d = outer diameter of the pipe. 2. angle of cut(θ) ≥ 22.5° if the above condition met, use the below equation (4c) of section 304.2.3. important note: single miter bend is rarely used, as it is not safe and reliable. in most of the cases, multiple miter bends are used. In this video you will learn how to make a pipe miter cut offset in any degree with calculation and formula.we will make this procedure if there’s no availab.

Piping Y Branch Marking With Layout One Cut Miter Pipe Bend Any θ = angle of the miter cut r 2 = mean radius of the pipe = (d t) 2 d = outer diameter of the pipe. 2. angle of cut(θ) ≥ 22.5° if the above condition met, use the below equation (4c) of section 304.2.3. important note: single miter bend is rarely used, as it is not safe and reliable. in most of the cases, multiple miter bends are used. In this video you will learn how to make a pipe miter cut offset in any degree with calculation and formula.we will make this procedure if there’s no availab. 3 big pipe c f round marking. 4 small pipe center line. 5 small pipe od marking. 6 degree pipe center line. 7 degree pipe od marking. 8 small pipe miter cut line. after all center line marking small pipe od inside round marking and drowning sem layout. and mark the one straight line and check all cut back dimension 12345. this is marking 8. Generally, miter bend can be fabricated in 3 parts, 4 parts, 5 parts, 6 parts etc. in miter bend ends parts are smaller than the middle parts, normally the middle part is a double of the ends parts or the last parts. in this calculator, you have to enter inputs as no. of parts in which you are going to fabricate your miter bend.

Comments are closed.