Pipe True Length Calculation Between A Tee And An Elbow Easy Formula

Pipe True Length Calculation Between A Tee And An Elbow Easy Formula Pipe true length calculation tutorial for beginners. between an equal tee and a long radius elbow. @technicalstudies. donate paypal.me technicalstudi. Please share the videos with your friends. piping, pressure vessels, storage tanks, structural fabrication and erection tutorialspipe true length calculation.

Pipe True Length Calculation Between A Tee And An Elbow Easy Formula Step 1: finding out the face allowance. so, to find out the fa, we know the expression, fa = fc – te. = 49.3 mm – 17.8 mm. = 31.5 mm. as we are considering a cc measurement, there will be two fittings, and thus two face allowances will be calculated by simply multiplying the fa we have just found with two. Rolling offset calculator. when running pipes or conduits, it is common to have to change the run of the line of pipes by using two equal angled elbow fittings (see diagram). the length of the run (r) and travel (t) created with the elbows and the length of pipe between them, can be calculated if one knows the vertical and horizontal offsets. Step 1: back to school. alright so let go back to school for a second and remember what a hypotenuse is. in geometry, a hypotenuse is the longest side of a right angled triangle, the side opposite of the right angle. the length of the hypotenuse of a right triangle can be found using the pythagorean theorem. the pythagorean theorem can be used. Example: 90 degree elbow equivalent length. for example, a 100 mm flanged regular 90 degree elbow with a minor loss coefficient of 0.3 and connected to a steel pipe with a friction factor of 0.03 will have an equivalent length equal to 1 meter, as shown in the calculations below.

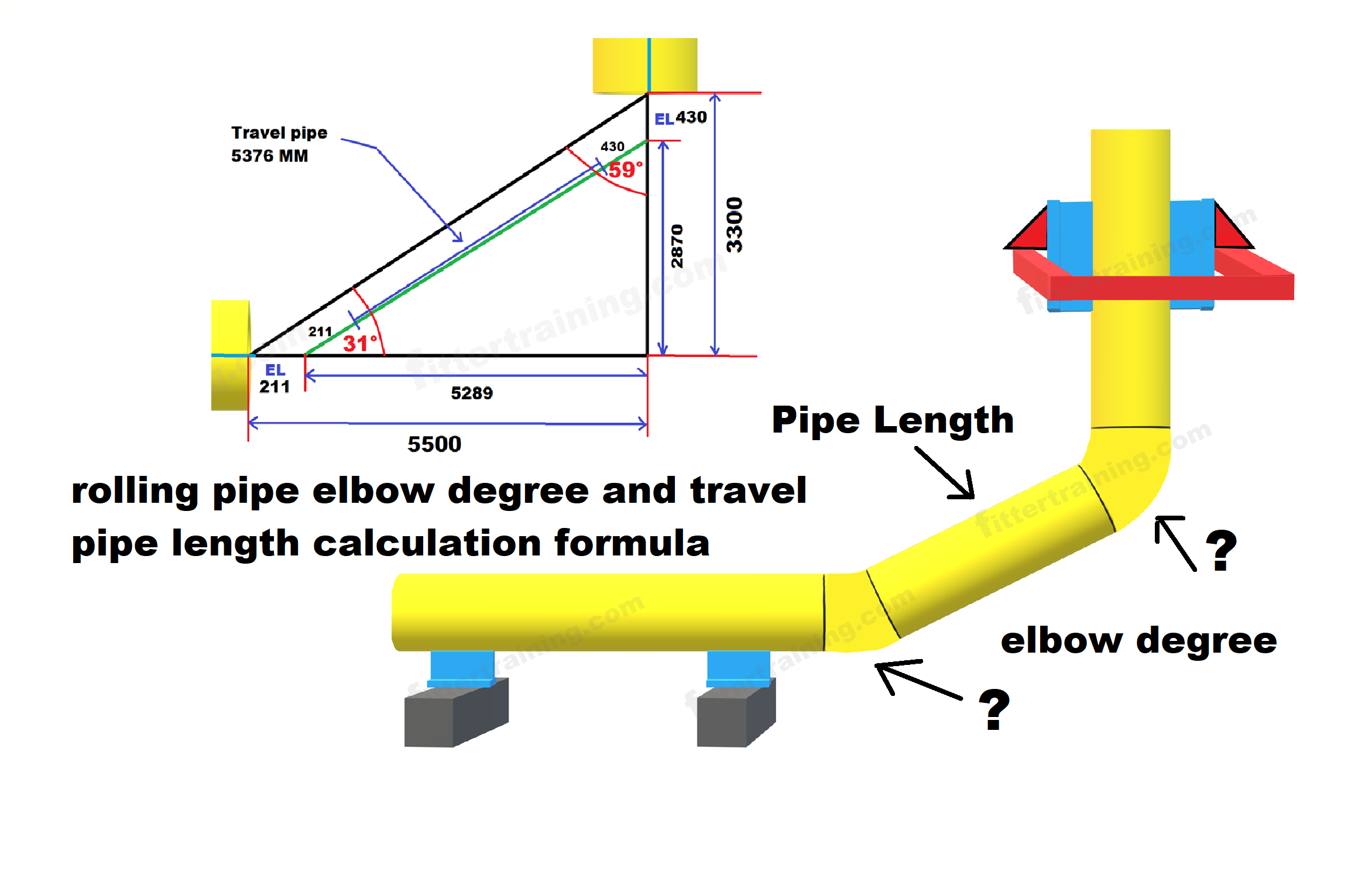

Rolling Pipe Elbow Degree And Travel Pipe Length Calculation Formula Step 1: back to school. alright so let go back to school for a second and remember what a hypotenuse is. in geometry, a hypotenuse is the longest side of a right angled triangle, the side opposite of the right angle. the length of the hypotenuse of a right triangle can be found using the pythagorean theorem. the pythagorean theorem can be used. Example: 90 degree elbow equivalent length. for example, a 100 mm flanged regular 90 degree elbow with a minor loss coefficient of 0.3 and connected to a steel pipe with a friction factor of 0.03 will have an equivalent length equal to 1 meter, as shown in the calculations below. Required pipe length for miter bend or miter elbow. as per the numbers of the miter or miter cut, draw a sketch as below fig 4: pipe length calculation formula for miter bend . we have all the required values now, put in the formula and we can get the total length where, m = crotch length =90 mm d = outside diameter of the pipe = 323.8 mm. The equivalent length method (l d ratio) allows the user to describe the pressure drop through a fitting as a length of pipe. in theory the pressure drop through the fitting is equivalent to the pressure lost through a certain length of piping at that corresponding flow rate. the most accurate way to use this method is when tabulated data is.

Pipe True Length Calculation Youtube Required pipe length for miter bend or miter elbow. as per the numbers of the miter or miter cut, draw a sketch as below fig 4: pipe length calculation formula for miter bend . we have all the required values now, put in the formula and we can get the total length where, m = crotch length =90 mm d = outside diameter of the pipe = 323.8 mm. The equivalent length method (l d ratio) allows the user to describe the pressure drop through a fitting as a length of pipe. in theory the pressure drop through the fitting is equivalent to the pressure lost through a certain length of piping at that corresponding flow rate. the most accurate way to use this method is when tabulated data is.

Threaded Pipe True Length Calculation Youtube

Pipe Elbow Center Calculation Formula For Fitters And Fabricators Youtube

Comments are closed.