Pipe Equal Tee Branch Marking And Cutting Formula Equal Tee Branch Formula

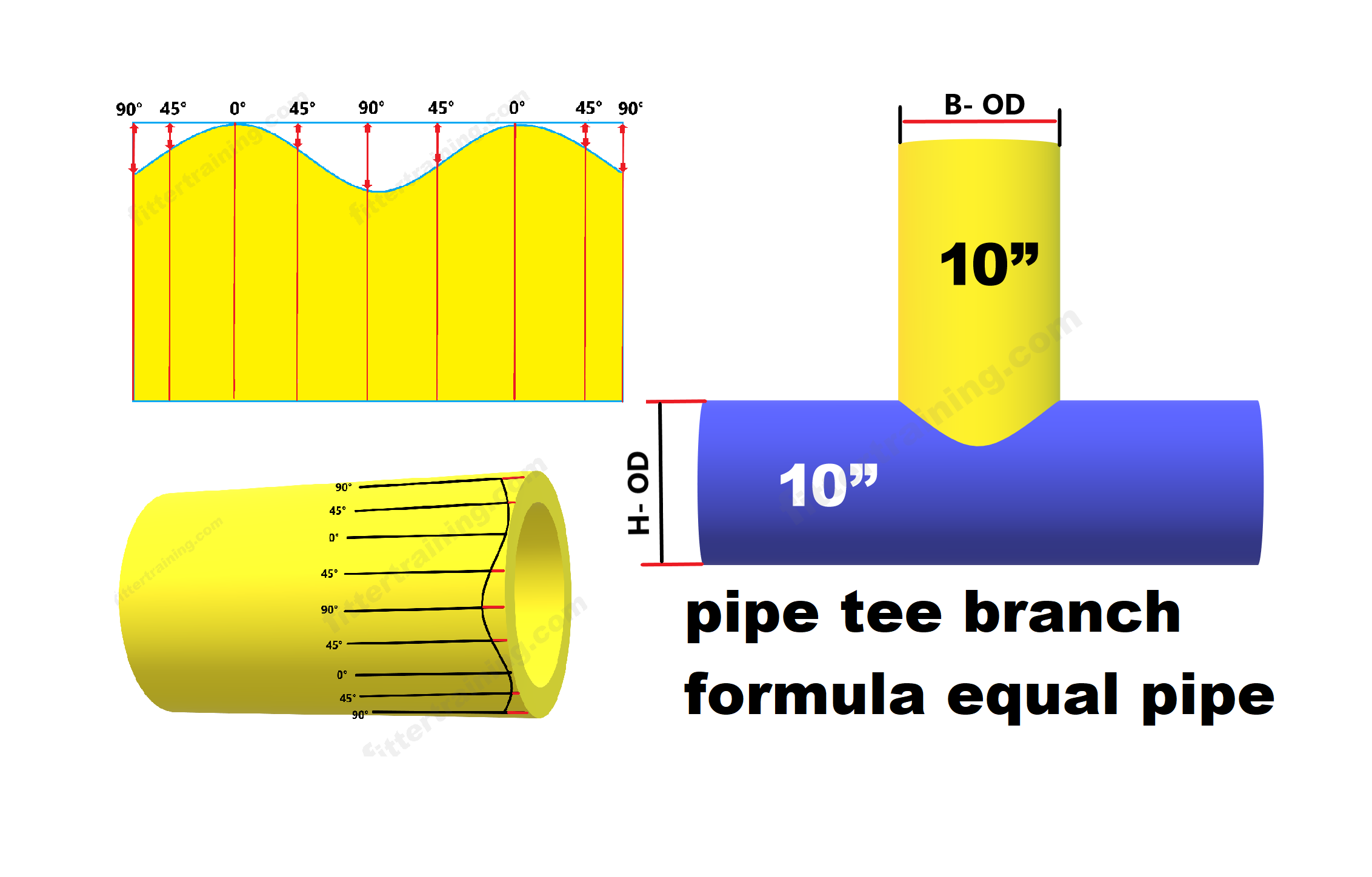

Layout And Development Of Pipe Branch 90 Degree Pipe Equal Tee Branch In this video tell about circumference of pipe and divide circumference of 4 inch of pipe in 16 lines for applying equal tee branch formula equal tee branch. Equal tee branch formula | equal saddle formula | equal tee branch marking cutting fitting equal tee branch formula equal tee cutting saddle formula equal te.

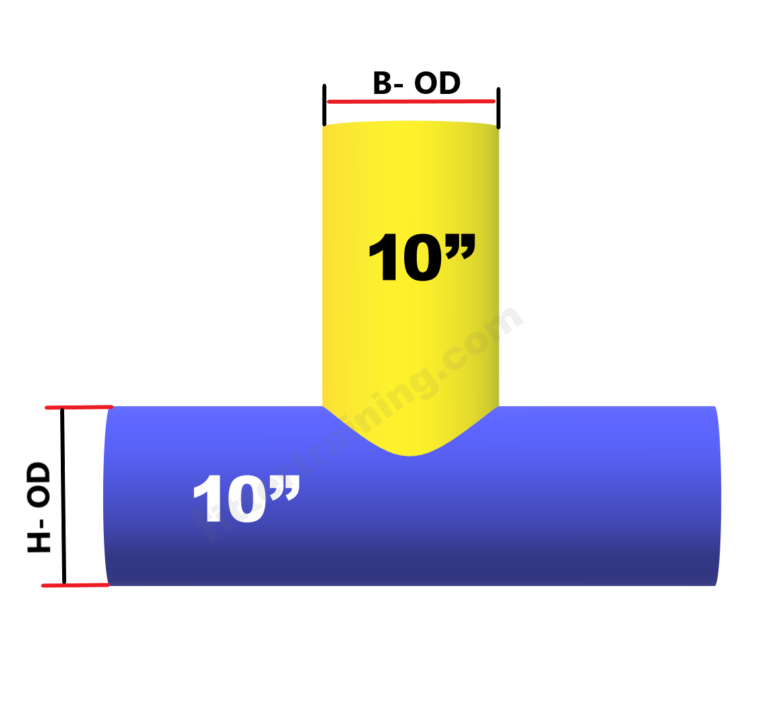

Pipe Tee Branch Formula Equal Pipe Tee Type Pipe Support Fitter This calculator is also used to layout branch pipe to pipe, 90 degree tee, equal tee, unequal tee, 90 degree pipe connections, radial pipe nozzles, axial pipe nozzles, pipe branch cutting, pipe tee branch, pipe y formation, and it is based on the pipe branch cutting formula. In these video we will learn about the formulas to fabricate the u equal tee branch with detailed explanation. also watch part 2 for remaining www . Example 45° degree lateral tee branch marking. pipe od × 1.2071 = l cut marking. pipe od × 0.2071 = s cut marking. sin ( 45 ) = 0.707106. 0.707106 × l = marking l side 45° degree center line cut back. 0.707106 × s = marking s side 45° degree center line cut back. equal pipe lateral pipe branch marking 16 center line. The main run pipe has often termed a header and the other as a branch. the branch size may be smaller or equal to the run pipe size but it cannot be larger. tees having branch size equal to run size are called equal tees & others as unequal tees or reducing tees. tees are normally designed based on asme b16.9 or asme b16.11.

Pipe Tee Branch Formula Equal Pipe Tee Type Pipe Support Fitter Example 45° degree lateral tee branch marking. pipe od × 1.2071 = l cut marking. pipe od × 0.2071 = s cut marking. sin ( 45 ) = 0.707106. 0.707106 × l = marking l side 45° degree center line cut back. 0.707106 × s = marking s side 45° degree center line cut back. equal pipe lateral pipe branch marking 16 center line. The main run pipe has often termed a header and the other as a branch. the branch size may be smaller or equal to the run pipe size but it cannot be larger. tees having branch size equal to run size are called equal tees & others as unequal tees or reducing tees. tees are normally designed based on asme b16.9 or asme b16.11. Finish the branch equal to outside diameter of run pipe and make a welding bevel of around 30°. place the branch with a gap by about 3 to 4 mm about the hole location on the run pipe, and tack weld the branch on a sufficient number of places. then the new branch can be completely welded. if de weld is ready, depending on the requirements non. Butt weld fitting tee tees straight and reducing. the primary purpose of a tee is to make a 90° branch from the main run of pipe. standard there are 2 possibilities, on behalf of the equal tee and reducing tee. the equal tee (or straight tee) is used as the branch has the same diameter as the run pipe.

Equal Pipe Branch Formula 90 Degree Make In Pipe Tee Branch With Formula Finish the branch equal to outside diameter of run pipe and make a welding bevel of around 30°. place the branch with a gap by about 3 to 4 mm about the hole location on the run pipe, and tack weld the branch on a sufficient number of places. then the new branch can be completely welded. if de weld is ready, depending on the requirements non. Butt weld fitting tee tees straight and reducing. the primary purpose of a tee is to make a 90° branch from the main run of pipe. standard there are 2 possibilities, on behalf of the equal tee and reducing tee. the equal tee (or straight tee) is used as the branch has the same diameter as the run pipe.

Comments are closed.