Pipe Elbow Miter Cut Formula Any Degree One Cut

Pipe Elbow Miter Cut Formula Any Degree One Cut A miter bend or miter elbow is prepared by mitering (angle cutting) and welding pipe ends of the cut pieces, usually at 45° and 90° to form a corner. there are two types of miter bend, one non perpendicular bend & another is 3 d bend. miter elbow bend is made from miter cut pieces of pipe. the miter pieces also called gores, there are two end. Solution: put the given value in equation (4a) where, θ = (bend angle numbers of miter or cut) 2 = (90° 2) 2 = 22.5 °. therefore, pm = 103.60 psi. we can see pm < pdesign. so, increase the numbers of the miter to 3 and recalculate (only the value of θ (15 °) will be changed, rest will be the same.

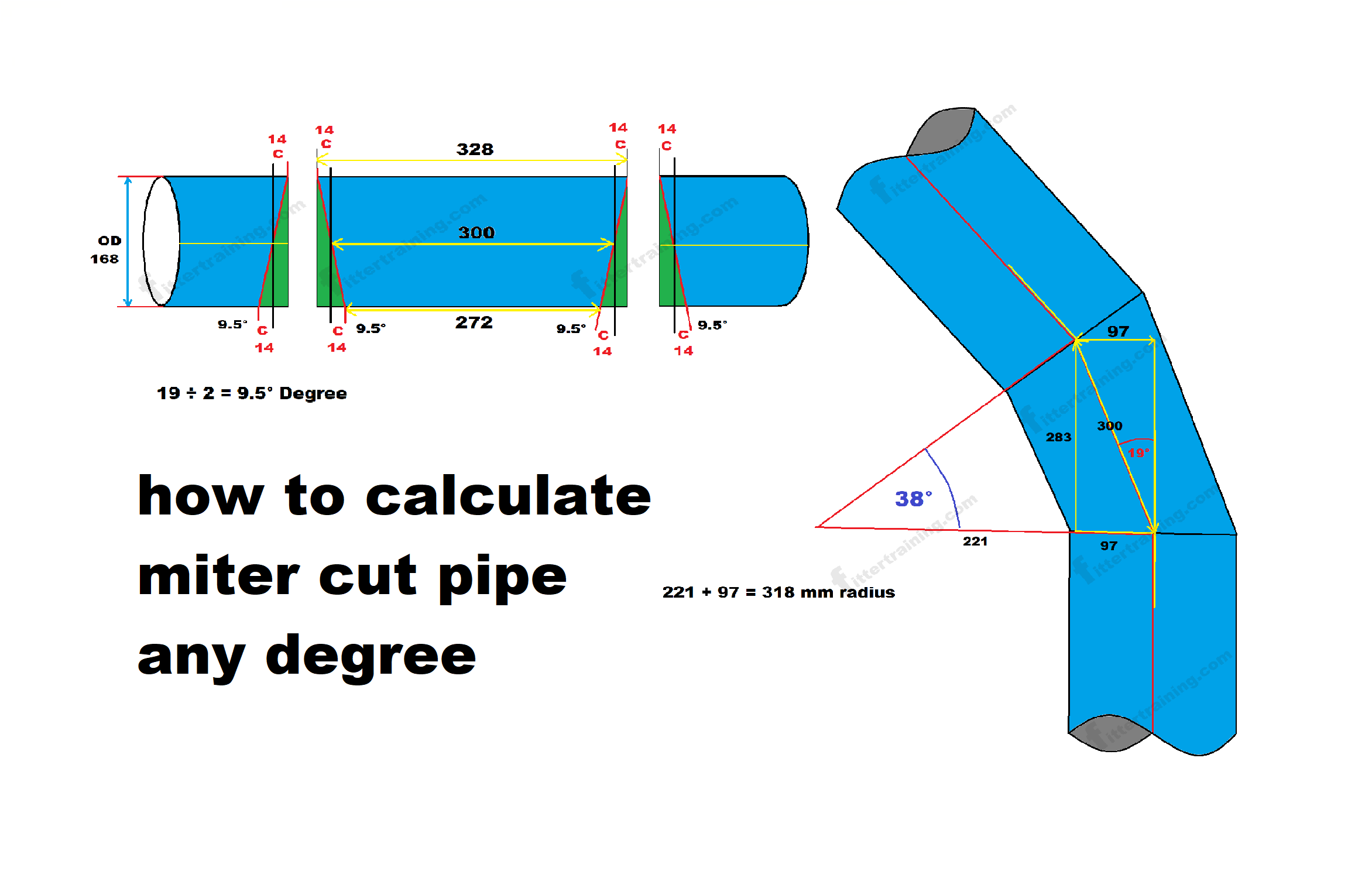

90 Degree Miter Pipe Bend Formula With Pipe Miter Cut Elbow Formula D : required elbow degrees. n : numer of cuts. e : elbow center radius required. pod : pipe outside diameter. sample miter calculation. consider we want to create 90 degree elbow of 10″ size with elbow center radius same as standard elbow i.e. 381 mm. so we have input values as : d = 90 mm : required elbow degree; n = 4 : number of cuts; e. Inputs required for miter bend calculation. line size: 10″ nps. line moc: carbon steel (a106 gr. b) schedule number: sch 120 (for selecting the pipe for cutting the miter pieces or for calculating the pipe weight) bend angle: 90°. number of miters or cuts: 4. radius of miter bend: 3d = 3*10*25.4 = 762 mm. In this video tell about calculation and fabrication of pipe any degree miter cut in full detail with new formula with very easy way this channel tell about. Miter cut angle (α): the angle at which each pipe section is cut can be calculated as follows: α = θ (2 * n) where: α = miter cut angle (degrees) θ = total bend angle (degrees) n = number of miters. bend radius: asme b31.1 and b31.3 require that the bend radius (r) should be at least three times the nominal pipe diameter (d) for miter.

Pipe Elbow Miter Cut Formula Any Degree One Cut In this video tell about calculation and fabrication of pipe any degree miter cut in full detail with new formula with very easy way this channel tell about. Miter cut angle (α): the angle at which each pipe section is cut can be calculated as follows: α = θ (2 * n) where: α = miter cut angle (degrees) θ = total bend angle (degrees) n = number of miters. bend radius: asme b31.1 and b31.3 require that the bend radius (r) should be at least three times the nominal pipe diameter (d) for miter. Generally, miter bend can be fabricated in 3 parts, 4 parts, 5 parts, 6 parts etc. in miter bend ends parts are smaller than the middle parts, normally the middle part is a double of the ends parts or the last parts. in this calculator, you have to enter inputs as no. of parts in which you are going to fabricate your miter bend. A miter bend, also known as a miter or angle elbow, is a pipe fitting that allows for a change in direction while maintaining a continuous flow through the pipe. it consists of two pieces cut at an angle, which, when joined together, create a smooth, curved bend. the proper use of miter bend ensures the efficient movement of fluids or gases.

Pipe Miter Cut Elbow With Pdf Chart 60 90 Degree Generally, miter bend can be fabricated in 3 parts, 4 parts, 5 parts, 6 parts etc. in miter bend ends parts are smaller than the middle parts, normally the middle part is a double of the ends parts or the last parts. in this calculator, you have to enter inputs as no. of parts in which you are going to fabricate your miter bend. A miter bend, also known as a miter or angle elbow, is a pipe fitting that allows for a change in direction while maintaining a continuous flow through the pipe. it consists of two pieces cut at an angle, which, when joined together, create a smooth, curved bend. the proper use of miter bend ensures the efficient movement of fluids or gases.

How To Calculate Miter Cut Pipe Any Degree Fitter Training

Mitter Cut Formula प इप क एल ब बन न क फ र म ल Pipe Elbow Miter

Comments are closed.