Pdf Case Study 08q127 Risk Based Inspection Rbi Root Cause

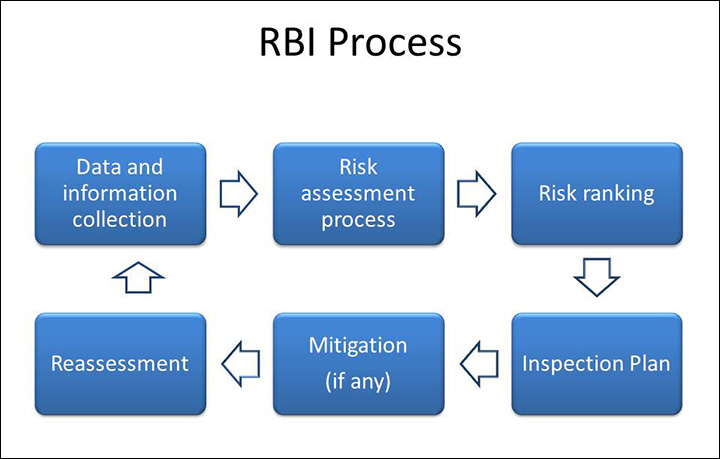

Pdf Case Study 08q127 Risk Based Inspection Rbi Root Cause The risk based inspection (rbi) method was chosen because the oil and gas processing industry have a high level of risk so that safety for business management and environmental conditions is the. A risk based inspection. approach permits the shift of inspection and maintenance resources to provide a higher level. of coverage on high risk items and an appropr iate effort on lower risk.

Risk Based Inspection Rbi The Hendrix Group This data is used to create refractory wear trends, risk assessments, and predict remaining refractory life. two case studies were presented to demonstrate the quality of the inspection data. the decision for optimum inspection methodologies and frequencies is based on risk assessments of each part of an asset. Pdf | risk based inspection (rbi) has been implemented mainly in oil and gas industry to manage the risk of aging facilities. this is a semi quantitative study on primary data collected. This literature review aims to offer a comprehensive review concerning the benefit of machine learning in managing the risk while incorporating time series forecasting studies and an overview of risk based inspection (rbi) methods (e.g. quantitative, semi quantitative, and qualitative). inspection and maintenance methods development have a pivotal role in preventing the uncertainty induced. Following the completion of the rbi and planning program implementation, the results from the data will be used to extend the turnaround interval to beyond the facility’s existing six year requirement. the company can now optimize its “unit” turnarounds per a risk based model instead of a pre determined interval.

Risk Based Inspection Rbi Pdf Risk Risk Management This literature review aims to offer a comprehensive review concerning the benefit of machine learning in managing the risk while incorporating time series forecasting studies and an overview of risk based inspection (rbi) methods (e.g. quantitative, semi quantitative, and qualitative). inspection and maintenance methods development have a pivotal role in preventing the uncertainty induced. Following the completion of the rbi and planning program implementation, the results from the data will be used to extend the turnaround interval to beyond the facility’s existing six year requirement. the company can now optimize its “unit” turnarounds per a risk based model instead of a pre determined interval. So, this study will use the risk based inspection (rbi) method to determine the level of risk from a pressure vessel. the risk based inspection (rbi) method was chosen because the oil and gas processing industry have a high level of risk so that safety for business management and environmental conditions is the main consideration. another. Practices of risk based inspection. risk based inspection (rbi) offers practical ways for the implementation of an inspection process that provides to maintenance actors a method of assessing the probability and effect of failure, evaluating risk level and generating the kinds of relevant actions that can lead to development of required risk.

Comments are closed.