Oring Face Identification 101 How To Identify Orf Hydraulic Fittings

O Ring Face Identification 101 How To Identify Orf Hydraulic Fittings Tutorial on how to identify orf (o'ring face) adapter fittings, hose ends. comments, questions always welcome. additional information available @ clearwa. No, orb (o ring boss) and orfs (o ring face seal) are not the same. orb fittings use an o ring located in a groove on a male threaded part to create a seal inside a female threaded port. orfs fittings have an o ring positioned on the flat face of the male fitting, sealing against a flat surface on the female fitting, providing a more robust.

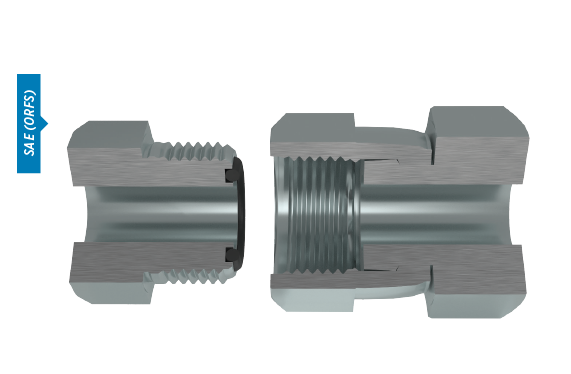

How To Identify O Ring Face Seal Hydraulic Fittings Youtube Sae j1453 (orfs) o ring face seal connections are considered the best for leak control. the male connector has a straight thread and an o ring in the face. the female has a straight thread and a machined flat face. the seal takes place by compressing the o ring onto the flat face of the female, similar to the split flange type fitting. O ring face seal (orfs) 60 degree npsm swivel. 60 degree cone (bspp) 60 degree cone (metric) to determine the type you're actually working with, there's a simple four step process involved. first of all, you need to figure out whether it's a permanent or reusable type, and the permanent fittings will be those which are crimped. Seal and is one of the best choices for a leak free connection.as the name implies, o ring face seal (orfs) fittings incorporate an o ring at the face of the fitting and are. designed to eliminate leaks in high pressure hydraulic systems. made to sae j1453 standard, orfs connections typically use buna n or viton, 90 duro. There are three main types of hydraulic hose fitting connections: o ring face seal fittings (orf): as the name suggests, an o ring is on the face of the fitting. when the side with the o ring connects with the flat face of the female, a seal is formed. orfs are ideal for high pressure applications and can operate up to 6,000 psi.

O Ring Face Seal Fittings And Parker Flat Face O Ring Hydraulic Fitting Seal and is one of the best choices for a leak free connection.as the name implies, o ring face seal (orfs) fittings incorporate an o ring at the face of the fitting and are. designed to eliminate leaks in high pressure hydraulic systems. made to sae j1453 standard, orfs connections typically use buna n or viton, 90 duro. There are three main types of hydraulic hose fitting connections: o ring face seal fittings (orf): as the name suggests, an o ring is on the face of the fitting. when the side with the o ring connects with the flat face of the female, a seal is formed. orfs are ideal for high pressure applications and can operate up to 6,000 psi. Look for signs of wear, corrosion, or damage. regular inspections help identify issues before they lead to system failure. cleanliness is key: keep the hydraulic system, especially around fittings and seals, clean of dirt and debris. contamination is a leading cause of hydraulic system failures. Sae j518 flange fittings — sae j518 is used throughout the world to connect larger diameter tubing and pipe within the fluid power industry. minus the bolt sizes, sae j518 flanges are interchangeable with iso 6141, din 20066 and jis b 8363. these flanges come in two pressure classes. the standard is iso6162, and it includes sae code 61 and.

Fittings 101 Orfs Brennan Industries Look for signs of wear, corrosion, or damage. regular inspections help identify issues before they lead to system failure. cleanliness is key: keep the hydraulic system, especially around fittings and seals, clean of dirt and debris. contamination is a leading cause of hydraulic system failures. Sae j518 flange fittings — sae j518 is used throughout the world to connect larger diameter tubing and pipe within the fluid power industry. minus the bolt sizes, sae j518 flanges are interchangeable with iso 6141, din 20066 and jis b 8363. these flanges come in two pressure classes. the standard is iso6162, and it includes sae code 61 and.

How To Identify Npt Thread And Other Hydraulic Fitting Types Stucchi Usa

Comments are closed.