Oil Refinery Improving Efficiency And Process Management Horiba

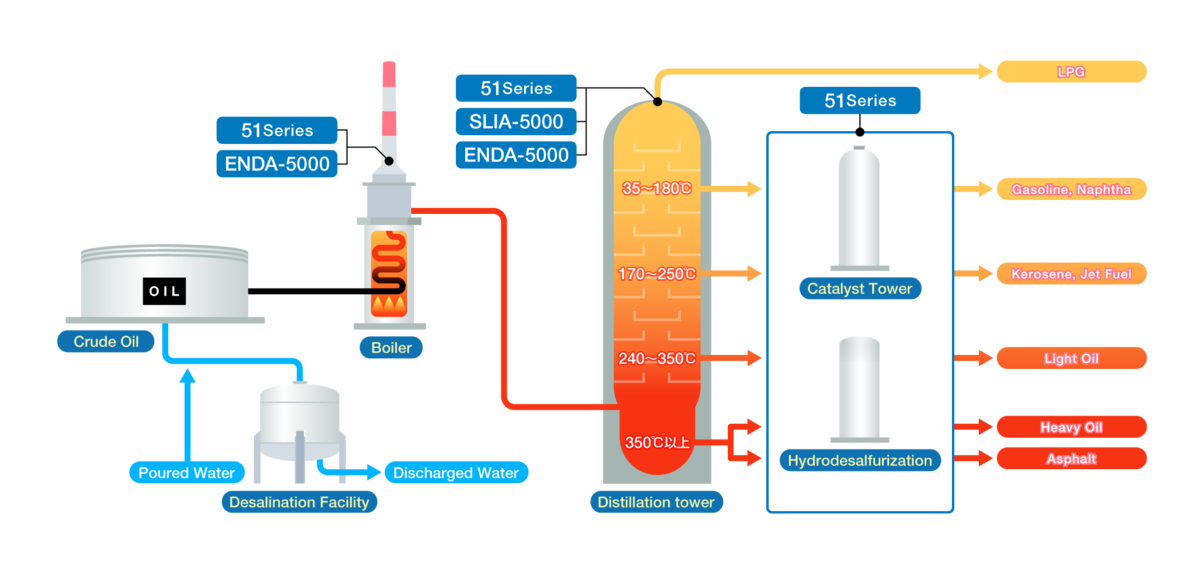

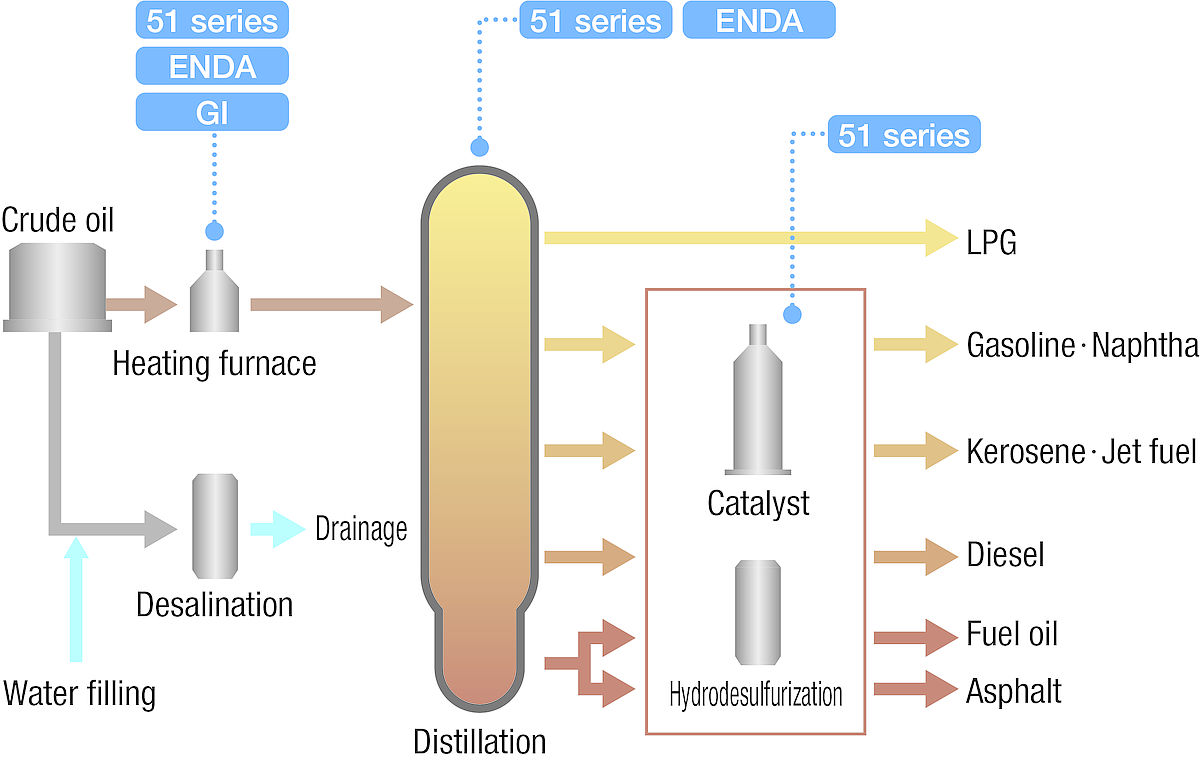

Oil Refinery Improving Efficiency And Process Management Horiba Use this form to contact our specialists. horiba contributes to improve the efficiency of monitoring various oil refinery processes with a wide lineup of analyzers. our explosion protection certified analyzers can be used even in locations with a risk of an explosive atmosphere due to the mixing of an inflammable gas, steam, dust, etc. Horiba provides a wide lineup of analyzers used to improve the efficiency of and to monitor various processes. we contribute to solving issues in the oil refining process by providing explosion protection certified analyzers to allow for use even in locations where there is a risk of an explosive atmosphere due to the mixing of an inflammable gas, steam, dust, etc.

Oil Refinery Improving Efficiency And Process Management 57 Off Wires energy environ 2016. energy efficiency in production always consists of three (3) key steps. 1 the first is to address the 'low hanging fruit', i.e. replacing light bulbs with energy saving ones, putting in frequency and speed controllers for drives and so on. development of own generation sources. How to improve production process for upstream oil and gas. enhancing production processes in the upstream oil and gas sector involves refining design and engineering workflows by shifting from reactive to proactive task management. implementing digital tools like digital twins, lean principles, and advanced work packaging can significantly. Refinery operating efficiency: improvement of oil refineries. posted on jan 17, 2023 at 10:01 pm. improving oil refineries to meet market and regulatory requirements faces many challenges in today's oil industry, with low profit margins, rising demand, high competition, and more stringent environmental requirements than ever before. Furthermore, the energy efficiency of the heavier cuts (vacuum residue) will depend on the refinery’s configuration (residue upgrading capacity) and type of crude being processed (heavy or light). argonne conducted an analysis of available residue upgrading units in u.s. refineries using the 2009 eia annual refinery capacity report (eia, 2009a).

Oil Refinery Improving Efficiency And Process Management 57 Off Refinery operating efficiency: improvement of oil refineries. posted on jan 17, 2023 at 10:01 pm. improving oil refineries to meet market and regulatory requirements faces many challenges in today's oil industry, with low profit margins, rising demand, high competition, and more stringent environmental requirements than ever before. Furthermore, the energy efficiency of the heavier cuts (vacuum residue) will depend on the refinery’s configuration (residue upgrading capacity) and type of crude being processed (heavy or light). argonne conducted an analysis of available residue upgrading units in u.s. refineries using the 2009 eia annual refinery capacity report (eia, 2009a). Main energy consumers at a refinery are fuel (heaters) – 74% 78% of total refinery consumption; steam generation (hps, mps and lps) – 18% 20% of total refinery consumption; and electricity (motors, tools, lighting) – 4% 6% of total refinery consumption. for example, increased plant capacity implies a proportional increase in raw material. The efficiency in the 30 oecd countries is worsening. crude oil production has a negative effect on the efficiency of the refining industry. if crude oil production increases by 1%, the efficiency of the refining industry will decrease by 0.1551%. this can be understood as the “resource curse” mentioned above.

Oil Refinery Improving Efficiency And Process Management 57 Off Main energy consumers at a refinery are fuel (heaters) – 74% 78% of total refinery consumption; steam generation (hps, mps and lps) – 18% 20% of total refinery consumption; and electricity (motors, tools, lighting) – 4% 6% of total refinery consumption. for example, increased plant capacity implies a proportional increase in raw material. The efficiency in the 30 oecd countries is worsening. crude oil production has a negative effect on the efficiency of the refining industry. if crude oil production increases by 1%, the efficiency of the refining industry will decrease by 0.1551%. this can be understood as the “resource curse” mentioned above.

Oil Refinery Improving Efficiency And Process Management 57 Off

Oil And Gas Monitoring Horiba

Comments are closed.