Main Engine Jacket Water Cooling System At Rodney Pendergast Blog

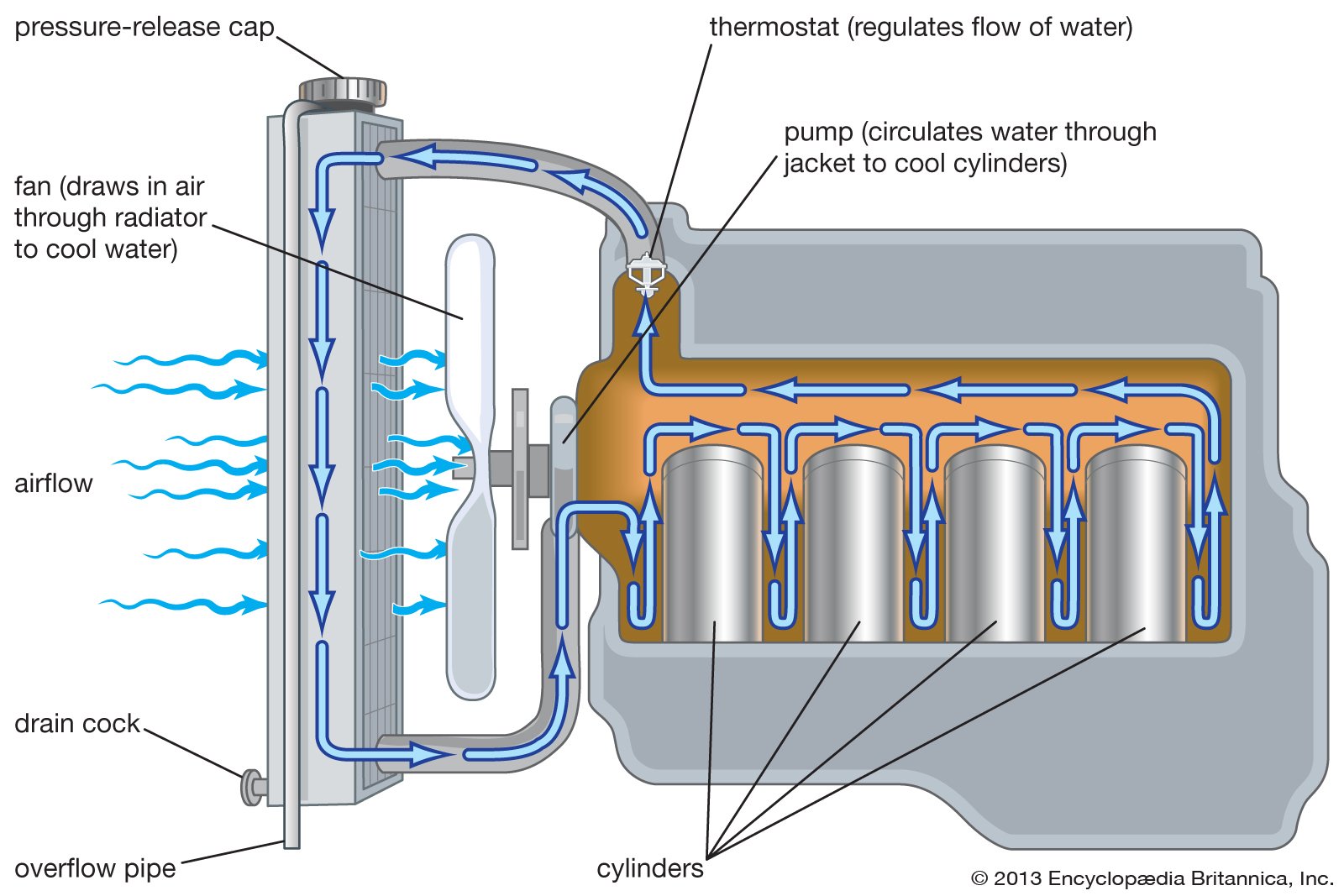

Main Engine Jacket Water Cooling System At Rodney Pendergast Blog De aerator was an essential part of engines incorporating water cooled pistons were air was deliberately introduced in to the system to aid the "cocktail shaker" cooling action. air or gas entering the system can lead to unstable and even total loss of cooling water pressure as the gas expands in the suction eye of the circulating pumps. Cooling can be done by dedicated coolers which cools the hot jacket water from the main engine. cooling medium is fresh water or sea water, in new ships central cooling systems are used, where fresh water as a cooling medium. circulating pump: there are two jacket water circulating pumps used onboard with a discharge pressure of 3 4 bars. the.

Main Engine Jacket Water Amarine antonio. there are 2 types of corrosion in marine diesel engine : cold corrosion hot corrosion cold corrosion : jacket water temp too low "eedi" compilation > cold cylinder cold > vapour form sox >acid > corrosion cold corrosion can be caused by low exhaust temperatures during very low load operations. care should be taken…. Fresh water evaporator. the fresh water generator (evaporator) installed in the engine room utilizes the heat available from the main engine jacket cooling water system to produce fresh water for use on board the vessel. in doing so the evaporator acts as a cooler for the main engine jacket cooling water system thus reducing the load on the. Jacket water cooling of main engine on ships has to be carried out in order to lower the temperature ponents of the this jw cooling system are cooler, two. Filling up of cooling water. directly after cleaning process of the cooling system, flush the system thoroughly with water until ph value to be about 7, and then drain the water. fill up the system with distilled water until the water level of the expansion tank to have margin for treatment. prepare the solution of inhibitor according to the.

Main Engine Jacket Water Jacket water cooling of main engine on ships has to be carried out in order to lower the temperature ponents of the this jw cooling system are cooler, two. Filling up of cooling water. directly after cleaning process of the cooling system, flush the system thoroughly with water until ph value to be about 7, and then drain the water. fill up the system with distilled water until the water level of the expansion tank to have margin for treatment. prepare the solution of inhibitor according to the. The cooling water supplied by the jacket cooling water pump is divided into two separate streams, the separation being made after the jacket water preheater. one stream, comprising of about 15% of the total cooling water flow, bypasses the cooler and is led directly to the engine; this is designated as the basic cooling stream. The high temperature (ht) cooling water system, also known as the jacket cooling water (jcw) system, is used for cooling the cylinder liners, cylinder covers and exhaust gas valves of the main engine and heating of the fuel oil drain pipes, see fig. 12.01.01. the jacket water pump draws water from the jacket water cooler outlet,.

Jacket Water Cooling System Of Main Engine Youtube The cooling water supplied by the jacket cooling water pump is divided into two separate streams, the separation being made after the jacket water preheater. one stream, comprising of about 15% of the total cooling water flow, bypasses the cooler and is led directly to the engine; this is designated as the basic cooling stream. The high temperature (ht) cooling water system, also known as the jacket cooling water (jcw) system, is used for cooling the cylinder liners, cylinder covers and exhaust gas valves of the main engine and heating of the fuel oil drain pipes, see fig. 12.01.01. the jacket water pump draws water from the jacket water cooler outlet,.

Main Engine Jacket Water

Comments are closed.