Klinger Kns Gaskets For High Pressure And Large Dimensions Assembly Between Flanges

Klinger Kns Klinger Gmbh Assembly of kns gaskets direct on the flange. bolts on the lower side are present in the flange’s bolt circle. the gasket is automatically centred. The assembly of the gasket. whenb all elements of the pipeline are mounted, the klinger ®kns gasket is assembled aside, raised through the "ears" provided for this purpose and then slipped between the flanges. material variety due to the flexible methods of production, the outer ring could be made of a high variety of materials –.

High Pressure Flange Gasket And High Pressure Steam Flange Gaskets Klinger ®kns compression stop for the pipeline and apparatus con struction in the gas and water area. a gasket with a compression stop is necessary at large diameters to cover the enormous forces at the flange, resulting from the pipe elongations tensions and the high number of bolts. on request, we are glad to provide gasket characteristics. It can also be sup plied with an internally sealed ptfe envelope. the filler strip for the outer gasket can be either ptfe or graphite, depending on the operating conditions. the standard material for the metal carrier of the inner gasket and for the metal strip of the spiral gasket is 1.4541 or 1.4571 steel. other materials available on request. Klinger ® kns gaskets, for high pressure and large dimensions! assembly between flanges. assembly between flanges. bitte akzeptieren sie marketing cookies um dieses video anzusehen. Klinger®kgs made of nbr acc. to din en 1514 1, shape ibc dn 100, pn 10 16. klinger®kgs s. rubber gasket, lenticular shape at the sealing body, with integral ly molded spear tip at the inside diameter of the gasket, rounded edges. the spear tip provides higher safety at lowest contact pressures.

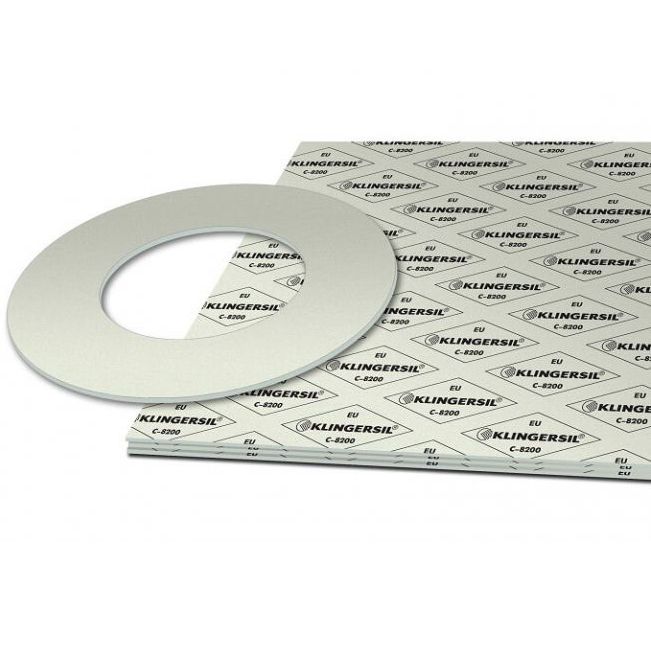

Glass Gasket Sheet Klingersil C 8200 Klinger Acid Resistant Klinger ® kns gaskets, for high pressure and large dimensions! assembly between flanges. assembly between flanges. bitte akzeptieren sie marketing cookies um dieses video anzusehen. Klinger®kgs made of nbr acc. to din en 1514 1, shape ibc dn 100, pn 10 16. klinger®kgs s. rubber gasket, lenticular shape at the sealing body, with integral ly molded spear tip at the inside diameter of the gasket, rounded edges. the spear tip provides higher safety at lowest contact pressures. The successful operation of a gasket depends upon a multiplicity of factors including the style and quality of the gasket material, but also the medium being sealed, the flange design, the amount of pressure applied to the gasket by the bolts and how the gasket is assembled onto the flanges and tightened. very basic causes often. Klinger kgs gaskets can be used in combination with all types of flange materials, ranging from plastic to steel, and are provided in a wide range of shapes and dimensions amongst others, the product offering includes the en 1514 1 as well as several sizes of the ansi standard. klinger kgs gaskets comprise the rubber types nbr, epdm, fkm.

Gasket Dimensions For Flanges The successful operation of a gasket depends upon a multiplicity of factors including the style and quality of the gasket material, but also the medium being sealed, the flange design, the amount of pressure applied to the gasket by the bolts and how the gasket is assembled onto the flanges and tightened. very basic causes often. Klinger kgs gaskets can be used in combination with all types of flange materials, ranging from plastic to steel, and are provided in a wide range of shapes and dimensions amongst others, the product offering includes the en 1514 1 as well as several sizes of the ansi standard. klinger kgs gaskets comprise the rubber types nbr, epdm, fkm.

Comments are closed.