Jacket Water Cooling System Of Main Engine Marine Diesel Engine

Jacket Water Cooling System Of Main Engine Marine Diesel Engine Cooling can be done by dedicated coolers which cools the hot jacket water from the main engine. cooling medium is fresh water or sea water, in new ships central cooling systems are used, where fresh water as a cooling medium. circulating pump: there are two jacket water circulating pumps used onboard with a discharge pressure of 3 4 bars. the. Filling up of cooling water. directly after cleaning process of the cooling system, flush the system thoroughly with water until ph value to be about 7, and then drain the water. fill up the system with distilled water until the water level of the expansion tank to have margin for treatment. prepare the solution of inhibitor according to the.

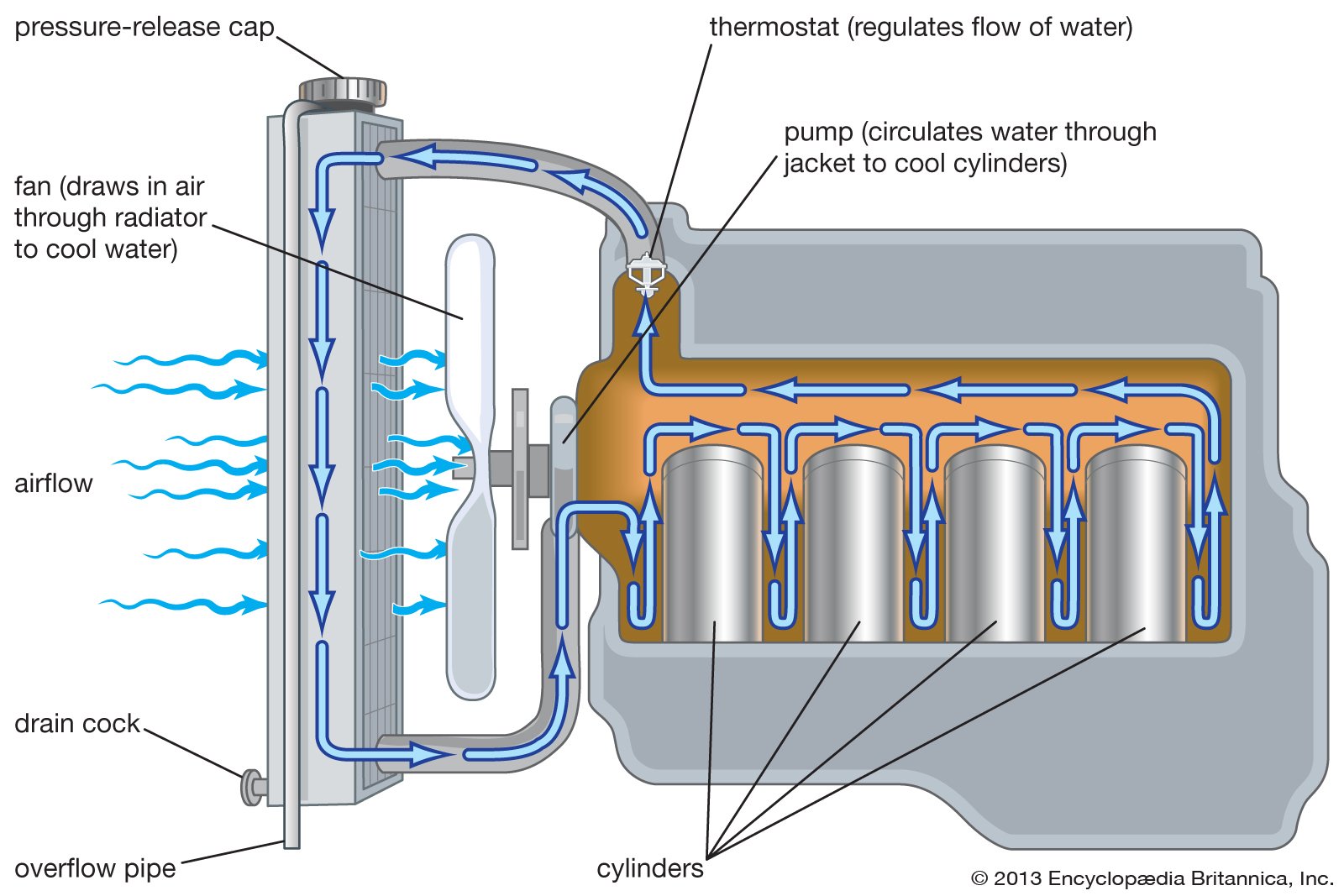

2 Stroke Diesel Engine Jacket Cooling Water System Marine Learning Freshwater cooling pipes are generally made of mild steel. a water cooling system for a slow speed diesel engine is shown in figure . it is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo blowers; the other for piston cooling. the cylinder jacket cooling water after leaving the engine passes to. A marine diesel engine cooling system is an essential component in ensuring the smooth operation and performance of a vessel’s engine. it plays a crucial role in maintaining the temperature of the engine and preventing overheating, which can lead to severe damage and potential breakdown. the primary function of a marine diesel engine cooling. Your diesel main engines and generators need efficient cooling for long service life. rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. traditional copper nickel engine coolers will fail over time and can pump raw sea water into the engines and. The high temperature (ht) cooling water system, also known as the jacket cooling water (jcw) system, is used for cooling the cylinder liners, cylinder covers and exhaust gas valves of the main engine and heating of the fuel oil drain pipes, see fig. 12.01.01. the jacket water pump draws water from the jacket water cooler outlet,.

Main Engine Jacket Water Your diesel main engines and generators need efficient cooling for long service life. rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. traditional copper nickel engine coolers will fail over time and can pump raw sea water into the engines and. The high temperature (ht) cooling water system, also known as the jacket cooling water (jcw) system, is used for cooling the cylinder liners, cylinder covers and exhaust gas valves of the main engine and heating of the fuel oil drain pipes, see fig. 12.01.01. the jacket water pump draws water from the jacket water cooler outlet,. A closed system has antifreeze or rust inhibitors on the water jacket side of the engine, while the salt water is used in place of a radiator. the antifreeze wears out and the energy release, which occurs millions of times during the running cycle in an engine, acts to remove tiny particulates of iron and aluminum from the engines’ water. A water cooling system for a slow speed diesel engine is shown in figure above. it is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo blowers; the other for piston cooling. the cylinder jacket cooling water after leaving the engine passes to a sea water.

Main Engine Jacket Water Cooling System At Rodney Pendergast Blog A closed system has antifreeze or rust inhibitors on the water jacket side of the engine, while the salt water is used in place of a radiator. the antifreeze wears out and the energy release, which occurs millions of times during the running cycle in an engine, acts to remove tiny particulates of iron and aluminum from the engines’ water. A water cooling system for a slow speed diesel engine is shown in figure above. it is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo blowers; the other for piston cooling. the cylinder jacket cooling water after leaving the engine passes to a sea water.

Comments are closed.