Internal Thread Verification Of Axle Flanges

Internal Thread Verification Of Axle Flanges Youtube A new vista sth integrated to verify the internal threaded holes in axle flanges. for more information on these systems please visit: newvistacor. The purpose of the go is to insure assembly with the mating external part. it does not measure the major or minor diameter of the internal thread. simply put, the go thread plug gage insures assembly with an in tolerance external thread. the no go thread plug gage only inspects the maximum functional pitch diameter of the internal part thread.

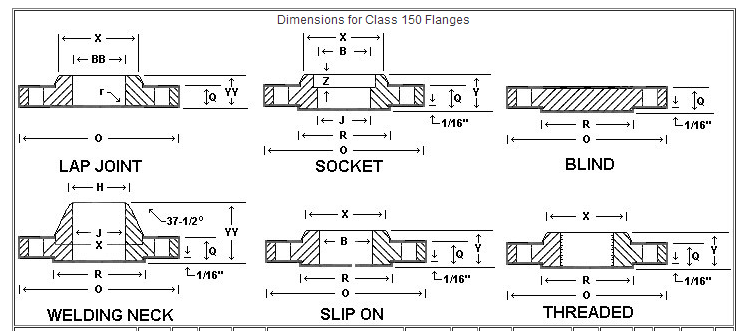

Internal Thread Verification With A New Vista Scc System New Vista Construction features. the threaded flange manufactured in accordance with asme b16.5 is similar to the slip on flange, but the bore shall have a taper pipe thread conforming to asme b1.20.1. the thread shall be concentric with the axis of the flange opening, and variations in alignment (perpendicular to the flange face) shall not exceed 5 mm. Here are general tolerance values for key dimensions of threaded flanges according to asme b16.5, suitable for various sizes and pressure classes: diameter of bolt circle (p): tolerance: ±1.6 mm (±1 16 inch) for flanges through nps 24, ensuring uniform distribution of bolt loads. diameter of bolt holes (q): tolerance: generally oversized. Threaded flanges – an overview. threaded flanges, called “screwed flanges,” are affixed to a pipe using a screw thread. the pipe’s end has a male thread, and the flange’s bore has a female thread. subsequently, the male threaded pipe is secured in the female threaded flange. the asme b1.20.1 compliant threaded flange is especially. A threaded flange connects a device securely to a pipe without the requirement of welding. it entirely relies on threads to create an unbreakable and leakage free connection between the flange and the pipe. they are also called screw flanges, a type of pipe flange with internal threads. there are mainly two threads: male and female thread.

Internal Thread Inspection With Anti Cross Threading Feature Youtube Threaded flanges – an overview. threaded flanges, called “screwed flanges,” are affixed to a pipe using a screw thread. the pipe’s end has a male thread, and the flange’s bore has a female thread. subsequently, the male threaded pipe is secured in the female threaded flange. the asme b1.20.1 compliant threaded flange is especially. A threaded flange connects a device securely to a pipe without the requirement of welding. it entirely relies on threads to create an unbreakable and leakage free connection between the flange and the pipe. they are also called screw flanges, a type of pipe flange with internal threads. there are mainly two threads: male and female thread. Threaded flanges are fittings used in piping systems with internal threads designed to connect to pipes or fittings with corresponding external threads. they offer a reliable and leak resistant joint without requiring welding, making them particularly useful in low pressure applications or where frequent disassembly is necessary. Size: ansi flanges come in a range of sizes from 1 2 inch to 24 inches. the size of the flange is determined by the nominal diameter of the pipe to which it is attached. pressure rating: ansi flanges are rated for different pressure levels, ranging from 150 to 2500.

An Integrated 4 Spindle Thread Verification System Inspecting Internal Threaded flanges are fittings used in piping systems with internal threads designed to connect to pipes or fittings with corresponding external threads. they offer a reliable and leak resistant joint without requiring welding, making them particularly useful in low pressure applications or where frequent disassembly is necessary. Size: ansi flanges come in a range of sizes from 1 2 inch to 24 inches. the size of the flange is determined by the nominal diameter of the pipe to which it is attached. pressure rating: ansi flanges are rated for different pressure levels, ranging from 150 to 2500.

Internal Thread Flange Tianjin Xinyuan Stainless Steel Co Ltd

Internal Thread Flange Tianjin Xinyuan Stainless Steel Co Ltd

Comments are closed.