Installation Guide For Ppr Pipes And Fittings Nb Qxhy

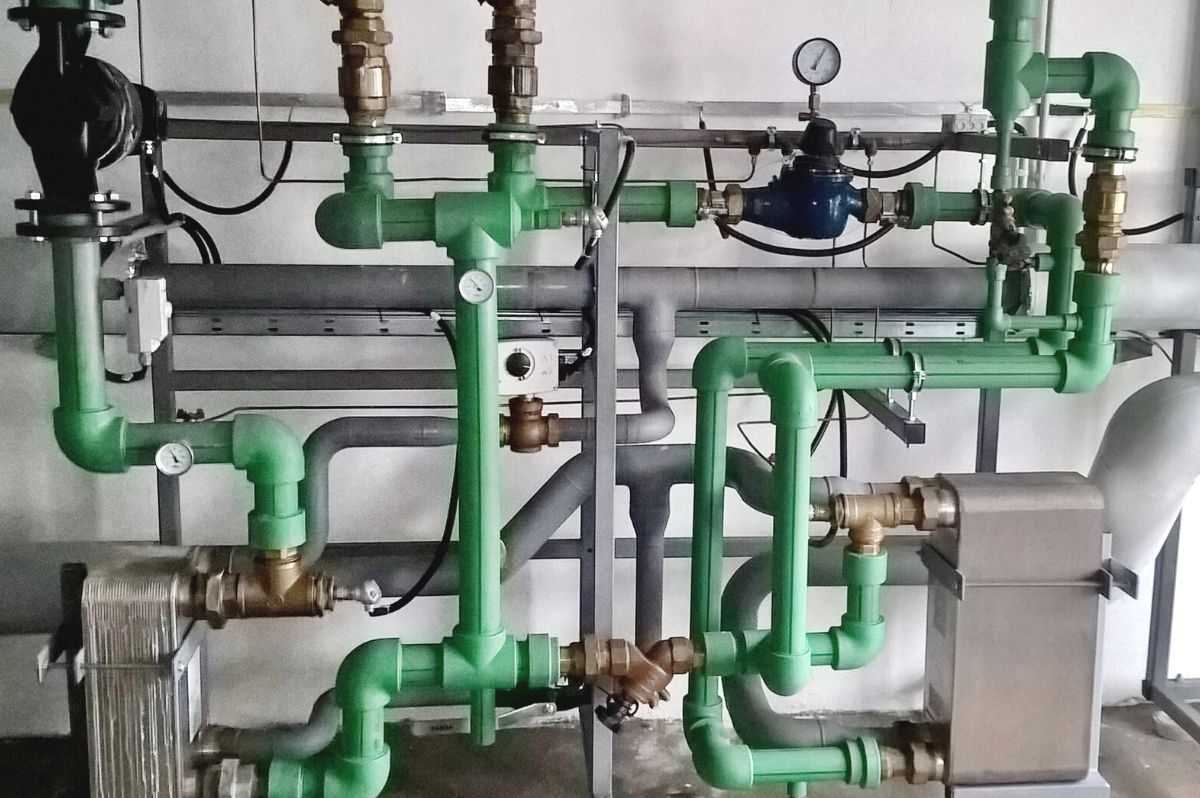

Installation Guide For Ppr Pipes And Fittings Nb Qxhy Before the pipe is welded, the surface of the pipe and the joint should be carefully cleaned, and the oil, impurities, and burrs on the surface of the pipe should be removed. it should be noted that the length of the pipe inserted into the pipe fitting should be appropriate, and a uniform flange should be formed at the pipe joint after connection. Connect the welding machine to a power source and set the appropriate temperature. insert the pipe ends into the welding machine and wait for the welding process to complete. join the pipes and fittings together and hold them in place until they cool and solidify. use a pressure test to check for leaks before continuing with the installation.

Installation Guide For Ppr Pipes And Fittings Nb Qxhy Schedule 40 fittings are one of our flagship products. we have many years of production experience, so the quality of pipe fittings is very stable. for size, we can provide the corresponding size according to your needs. please contact me and tell me your needs and we will meet you. (email: sales@nbqxhy ). Compared with metal pipes, plastic composite pipes are lighter, thinner, easier to transport, cut, and install, and can effectively shorten the construction time. 3. resource saving. plastic composite pipes use a combination of polymer materials and traditional materials. they can not only meet the functions of water supply and drainage pipes. Fusion is the process of joining ppr pipes and fittings to create a strong, leak proof connection: heat the pipe and fitting: use a fusion machine to heat the ends of the pipe and fitting. the temperature should typically be around 260°c (500°f), but always follow the manufacturer’s guidelines for specific temperatures and heating times. Heat welding machine. step 4: using your machine, heat up the ends of each pipe that will be joined until you can bend it by hand. step 5: before the material hardens, stuff the ends of both pipes into it at an angle. verify that the pipes and fitting are completely bonded with no space. step 6: keep the pipes steady as long as it takes for.

How To Install Ppr Pipes And Fittings Lifepluspipes Fusion is the process of joining ppr pipes and fittings to create a strong, leak proof connection: heat the pipe and fitting: use a fusion machine to heat the ends of the pipe and fitting. the temperature should typically be around 260°c (500°f), but always follow the manufacturer’s guidelines for specific temperatures and heating times. Heat welding machine. step 4: using your machine, heat up the ends of each pipe that will be joined until you can bend it by hand. step 5: before the material hardens, stuff the ends of both pipes into it at an angle. verify that the pipes and fitting are completely bonded with no space. step 6: keep the pipes steady as long as it takes for. This comprehensive guide explores the various types of ppr pipe fittings, their versatile applications across different industries, and their pivotal role in creating sustainable, efficient plumbing systems. ifan factory 30 years manufacture experience support color size customization support free sample.welcome to consult for catalog and free. Types of ppr pipe fittings. 2.1. ppr couplings. ppr couplings are essential components used to connect two pipes or pipe sections. they come in various sizes and are available in both socket and threaded versions. these fittings are used in domestic and industrial plumbing systems for joining pipes securely. 2.2.

How To Install Ppr Pipes And Fittings Lifepluspipes This comprehensive guide explores the various types of ppr pipe fittings, their versatile applications across different industries, and their pivotal role in creating sustainable, efficient plumbing systems. ifan factory 30 years manufacture experience support color size customization support free sample.welcome to consult for catalog and free. Types of ppr pipe fittings. 2.1. ppr couplings. ppr couplings are essential components used to connect two pipes or pipe sections. they come in various sizes and are available in both socket and threaded versions. these fittings are used in domestic and industrial plumbing systems for joining pipes securely. 2.2.

Installation Techniques For Ppr Pipes A Step By Step Guide China

Installation Techniques For Ppr Pipes A Step By Step Guide China

Comments are closed.