Indirect Direct Evaporative Cooling System Evapoler

Indirect Direct Evaporative Cooling System Evapoler Youtube Two stage evaporative cooling systems help in cooling the conditioning space with 100% fresh air. these are designed for 25 35 acph for better cooling and adequate ventilation. it is an eco friendly cooling system as no harmful refrigerants are used. evapoler uses hi efficiency sensible heat exchangers . Then use the dry bulb wet bulb values from step 3 to calculate the dry bulb wet bulb temperatures achievable with direct evaporative cooling: 4. temp drop achievable: (dry bulb – wet bulb ) x (efficiency of the media) example: (29 degrees – 19.5 degrees) x .9 = 8.6 degreesc. 5. achievable temp = dry bulb – temp drop achievable.

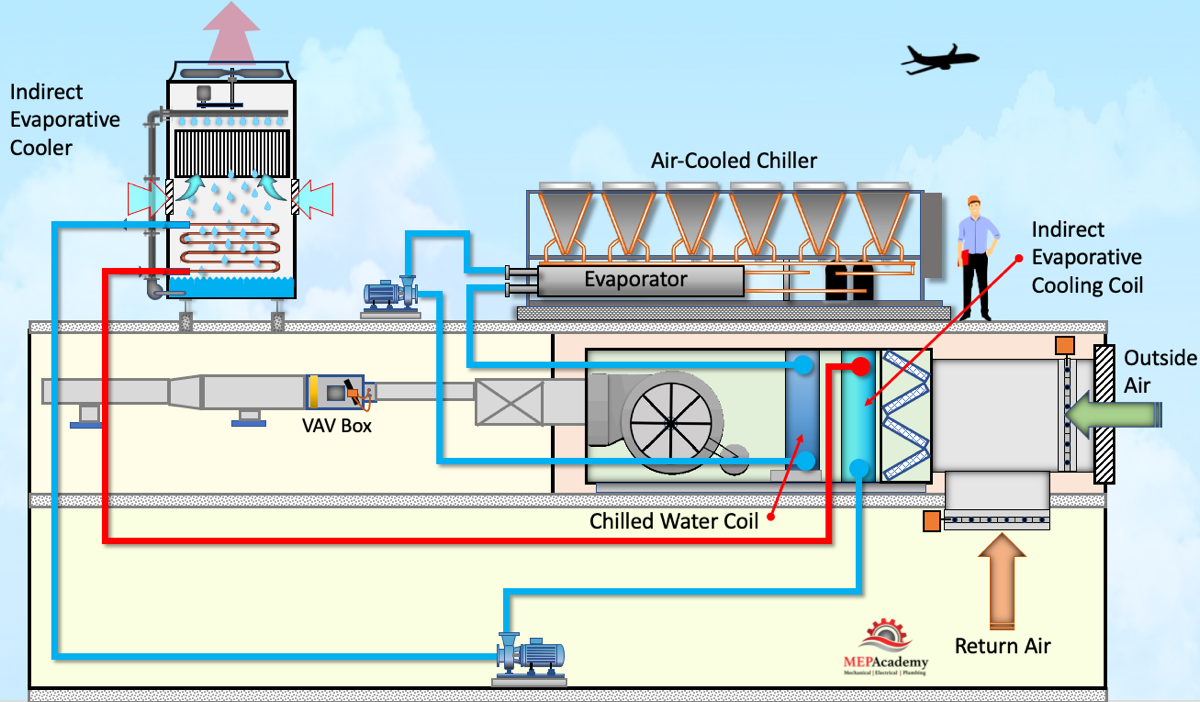

How Indirect Evaporative Coolers Work Mep Academy The efficiency of the direct evaporative cooling system is 90%, whereas the indirect cooling system has 60 70%. an indirect cooling system is perfect for areas where the outside temperature is hot and humid . the direct cooling system provides a stronger cooling effect in the areas where air is hot and dry. Two stage evaporative coolers are also known as indirect direct evaporative coolers.evapoler has used this two stage evaporative cooling system in replacemen. Benefits of oxycom's two stage evaporative cooling system. environmentally friendly alternative, with 90% lower energy consumption. cools up to 7 ℃ deeper than single step systems. brings up to 70% less moisture in the supplied air than direct systems. up to 30% less water consumption than single step systems. A two stage evaporative cooling system can deliver cool indoor air with a relative humidity in the 50% 65% range, while direct evaporative cooling systems typically condition the air at around 70% relative humidity. according to the american society of heating and engineers (ashrae), advanced two stage evaporative coolers can use 60% 75% less.

How Indirect Evaporative Cooling Works Youtube Benefits of oxycom's two stage evaporative cooling system. environmentally friendly alternative, with 90% lower energy consumption. cools up to 7 ℃ deeper than single step systems. brings up to 70% less moisture in the supplied air than direct systems. up to 30% less water consumption than single step systems. A two stage evaporative cooling system can deliver cool indoor air with a relative humidity in the 50% 65% range, while direct evaporative cooling systems typically condition the air at around 70% relative humidity. according to the american society of heating and engineers (ashrae), advanced two stage evaporative coolers can use 60% 75% less. The energy saving potential of indirect direct evaporative cooling system can be enhanced with the help of liquid desiccant system retrofitting. the addition of enthalpy exchanger before the ld unit improves the cop and cooling capacity. the dew point iecs results in 41% higher cooling capacity as compared to base case [63]. Indirect evaporative coolers feature a hyper efficient air to air heat exchanger. let’s see how it works: 1. hot air enters the cooler. hot outside air enters the cooler via the inlet. a powerful, energy efficient, electric fan moves the air towards the core. 2. hot air passes through the core. the core is an air to air heat exchanger.

Comments are closed.