In Line Ball Check Valve Overview Checkvalve Valve Valves

Check Valve What Is It How Does It Work Types Of The operation mechanism is simple, but the ball design makes it more expensive than the swing check valve. because it uses a flapper in place of a ball, it is cheaper. the cost difference could be significant when working on large projects with several valves. the water hammer is easily minimized by increasing the ball size. Ball check valve working principle. check valves are unidirectional valves that ensure media flows in only a single direction. there are several check valve styles that perform unidirectional media flow like a ball, piston, or disk style. a ball check valve can prevent the backflow of various media like gas, air, steam, vapor, or water lines.

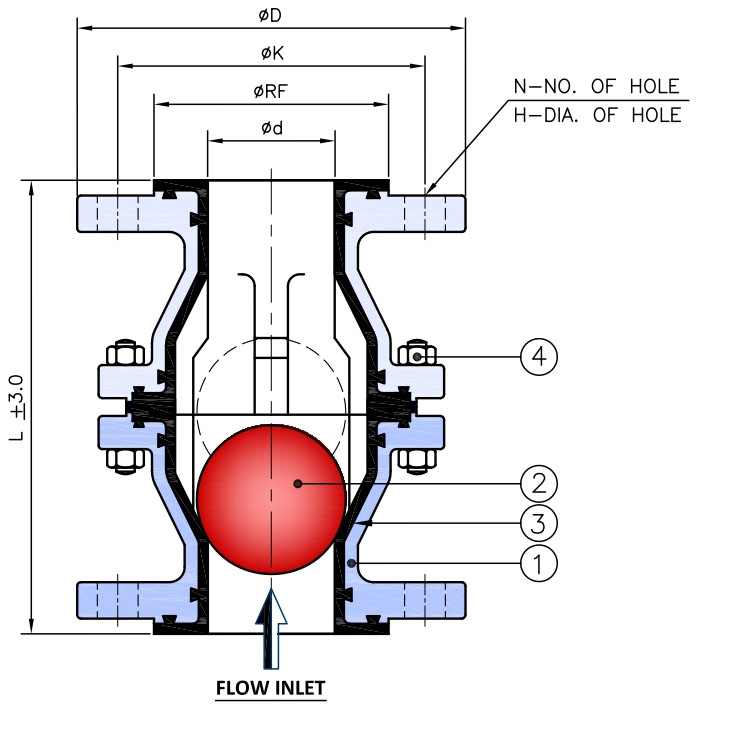

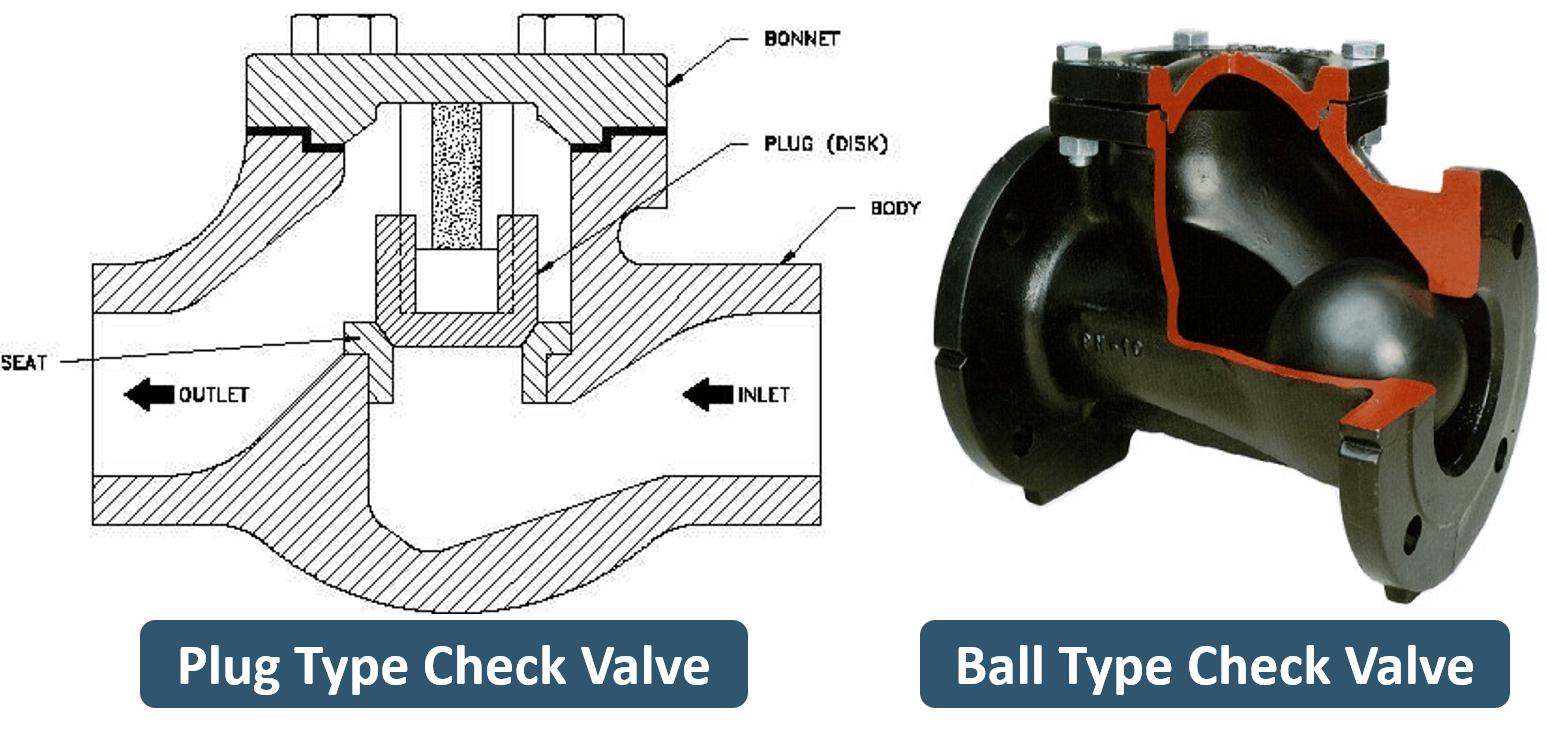

Ptfe Lined Ball Type Check Valve Ptfe Lined Ball Type Check Valve The body guide ensures alignment of the seat and disc when the valve closes. piston check valves are available from 1 4 inch to 24 inches and larger. smaller valves, 1 4 inch to 2 inches, are normally pro vided with a spring to assist in closing and to ensure the disc slides back to the seat when installed in vertical. #valves#oilfieldvalvewelcome back to everything valves. the channel dedicated to bringing you everything valves. thank you for everyone subscribed to the cha. Check valves are the disk type and the ball type. ball check valves ball check valves have a y body configuration. the closing portion of the valve is a ball, either spring loaded or gravity operated. during product flow, the ball is pushed up into the y branch of the valve out of the product stream; allowing full flow through the valve. The closed check valve prevents upstream flow back through the inlet port. positive flow towards the outlet or exit port causes the disc to lie against this seat. the media then flows around the disc, through the channels and out through the exit port of the check valve. 2. design considerations of check valves.

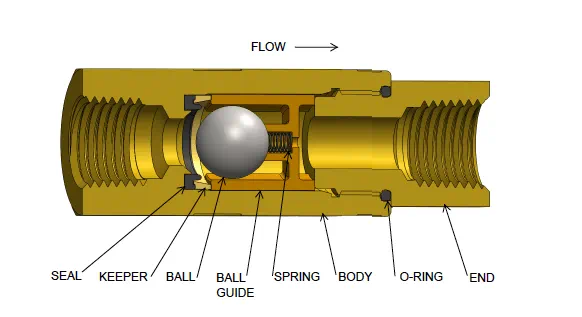

What Is A Check Valve Learn About Check Valves Types And Parts Check valves are the disk type and the ball type. ball check valves ball check valves have a y body configuration. the closing portion of the valve is a ball, either spring loaded or gravity operated. during product flow, the ball is pushed up into the y branch of the valve out of the product stream; allowing full flow through the valve. The closed check valve prevents upstream flow back through the inlet port. positive flow towards the outlet or exit port causes the disc to lie against this seat. the media then flows around the disc, through the channels and out through the exit port of the check valve. 2. design considerations of check valves. A ball check valve consists of a small, spherical shaped ball that sits inside a cylindrical chamber with an opening on each side. as liquid passes through it, the ball moves up and down within the chamber, enabling unrestricted fluid flow in one direction. a swing valve, meanwhile, operates similarly but instead of a ball it has a disc shaped. For inspection and maintenance, the valve would need to be fully removed from the line. fig.1 and fig.2 are examples of a spring loaded in line check valve that can be screwed in line to the pipe. this same concept can be applied to spring loaded y check valves.

In Line Ball Check Valve Overview Checkvalve Valve Valves Youtube A ball check valve consists of a small, spherical shaped ball that sits inside a cylindrical chamber with an opening on each side. as liquid passes through it, the ball moves up and down within the chamber, enabling unrestricted fluid flow in one direction. a swing valve, meanwhile, operates similarly but instead of a ball it has a disc shaped. For inspection and maintenance, the valve would need to be fully removed from the line. fig.1 and fig.2 are examples of a spring loaded in line check valve that can be screwed in line to the pipe. this same concept can be applied to spring loaded y check valves.

Check Valve Function Diagram Pdf Linquip

Check Valves Essential Guide Aquatech

Comments are closed.