How To Use A Compression Fitting Compression Plumbing Tutorial

How To Use A Compression Fitting Compression Plumbing Tutorial In this video i show how to use a brass compression fitting to join two copper pipes together. this is a quick tutorial to show how simple it really is to do. In this video i talk about uses and how to use compression fittings for plumbing applications. my name is tony, i have been a master plumber for over 30 year.

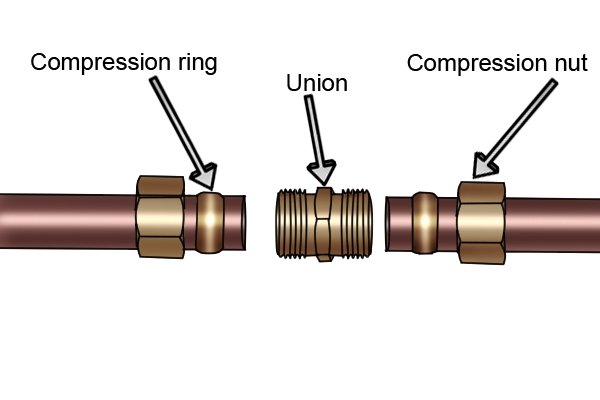

How To Use And Install A Compression Fitting Youtube Step 4: slide the components onto the pipe. begin by sliding the compression nut onto the pipe, followed by the ferrule (s). ensure that the nut is tightened and the tapered end of the ferrule (s) faces toward the fitting body. this arrangement ensures a secure and leak free connection. Intaplumb.co.uk a free lesson brought to you from intaplumb erith, a leading provider in plumbing, heating, gas and renewable energy qualifications. this. The use of softer tubing (such as polyurethane or vinyl) is not normally recommended with compression style fittings because the tubing wall is likely to collapse, or move away from the ferrule. this negates the holding power of the ferrule, and can also prevent the ferrule from making a leak tight seal around the full diameter of the tubing. Slide the compression ring up onto the tube and into the nut with the threaded side out. connect the tube or pipe that is to be fitted into the compression seat. slide the nut and the compression ring down toward the fitting body. screw the nut (and by proxy the ring) into the fitting body and tighten the connection with a wrench.

How To Fit A Compression Fitting Copper Pipe Tutorial Youtube The use of softer tubing (such as polyurethane or vinyl) is not normally recommended with compression style fittings because the tubing wall is likely to collapse, or move away from the ferrule. this negates the holding power of the ferrule, and can also prevent the ferrule from making a leak tight seal around the full diameter of the tubing. Slide the compression ring up onto the tube and into the nut with the threaded side out. connect the tube or pipe that is to be fitted into the compression seat. slide the nut and the compression ring down toward the fitting body. screw the nut (and by proxy the ring) into the fitting body and tighten the connection with a wrench. How to use a compression fitting. preparation: ensure the pipe or tubing ends are clean, smooth, and free from burrs or sharp edges. fitting assembly: slide the compression nut onto the pipe or tubing, followed by the compression ring (ferrule). insert the pipe into the fitting's body or socket until it reaches the desired depth. The compression nut is tightened clockwise to cause the compression sleeve to be squeezed between the fitting and the nut. as more pressure is applied to the nut, the ends of both sides of the sleeve dig slightly into the pipe on both sides of the sleeve, causing the sleeve to be compressed on to the tubing.

How To Install A Compression Valve Compression Fitting Tutorial How to use a compression fitting. preparation: ensure the pipe or tubing ends are clean, smooth, and free from burrs or sharp edges. fitting assembly: slide the compression nut onto the pipe or tubing, followed by the compression ring (ferrule). insert the pipe into the fitting's body or socket until it reaches the desired depth. The compression nut is tightened clockwise to cause the compression sleeve to be squeezed between the fitting and the nut. as more pressure is applied to the nut, the ends of both sides of the sleeve dig slightly into the pipe on both sides of the sleeve, causing the sleeve to be compressed on to the tubing.

How To Use A Compression Waste Fitting Waste Compression Plumbing

How To Create A Compression Fitting Using A Compression Fitting Spanner

Comments are closed.