How To Install Ppr Pipes And Fittings Installation Jointing Method For Ppr Pipe Pipe Fitting

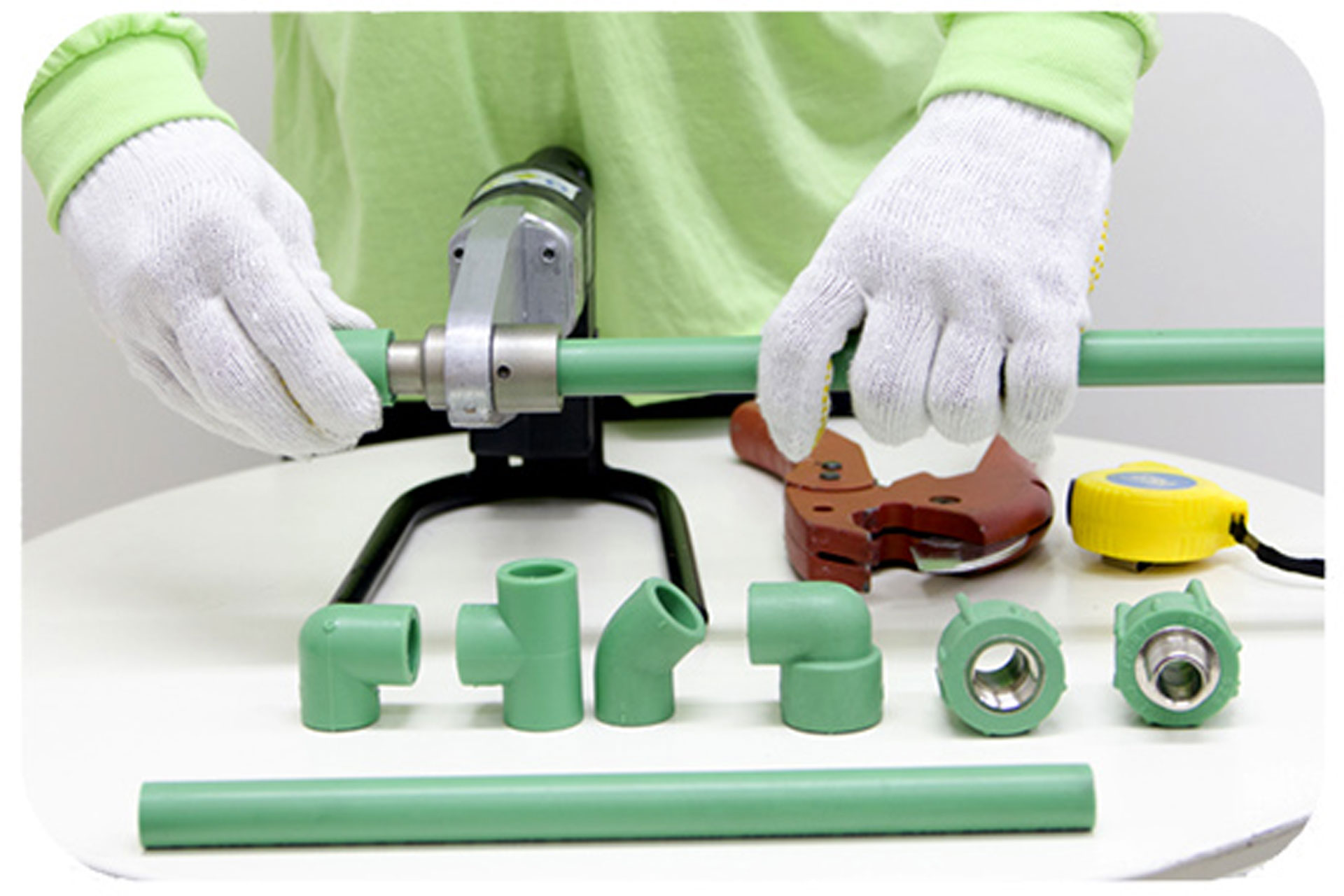

Installation Guide For Ppr Pipes And Fittings Nb Qxhy 4. clean the ppr pieces with a cloth and the recommended cleaner. your fusion tool kit will likely recommend, and may even come with, a specific cleaner to use with ppr pipe. use this cleaner as directed on the outside of the pipe and the inside of the fitting to be joined. let the pieces dry for a few moments. This is an installation video guide for "how to joint pp r pipe & fittings ".

Ppr Pipe Joint And Installation Ppr Installation Ppr Pipe Welding 📢 #handmadecreativechannel📢📢 subscribe my channel channel ucae0is3guw3ttqup4xgqz7q?sub confirmation=1 📢hello friends, in this. In this video we learn how to make welding joint in ppr pipe installation make sure to subscribe to our channel to get the newest stuff first. t. Mark the welding depth on the ppr pipe wall with a marker; 5. at the same time, insert the pipes and fittings of ppr into the welding device and heat them according to the specified time; 6. after heating, push the pipe and pipe vertically and hold it for more than 5 seconds. don't use too much force in case it bends. Fusion is the process of joining ppr pipes and fittings to create a strong, leak proof connection: heat the pipe and fitting: use a fusion machine to heat the ends of the pipe and fitting. the temperature should typically be around 260°c (500°f), but always follow the manufacturer’s guidelines for specific temperatures and heating times.

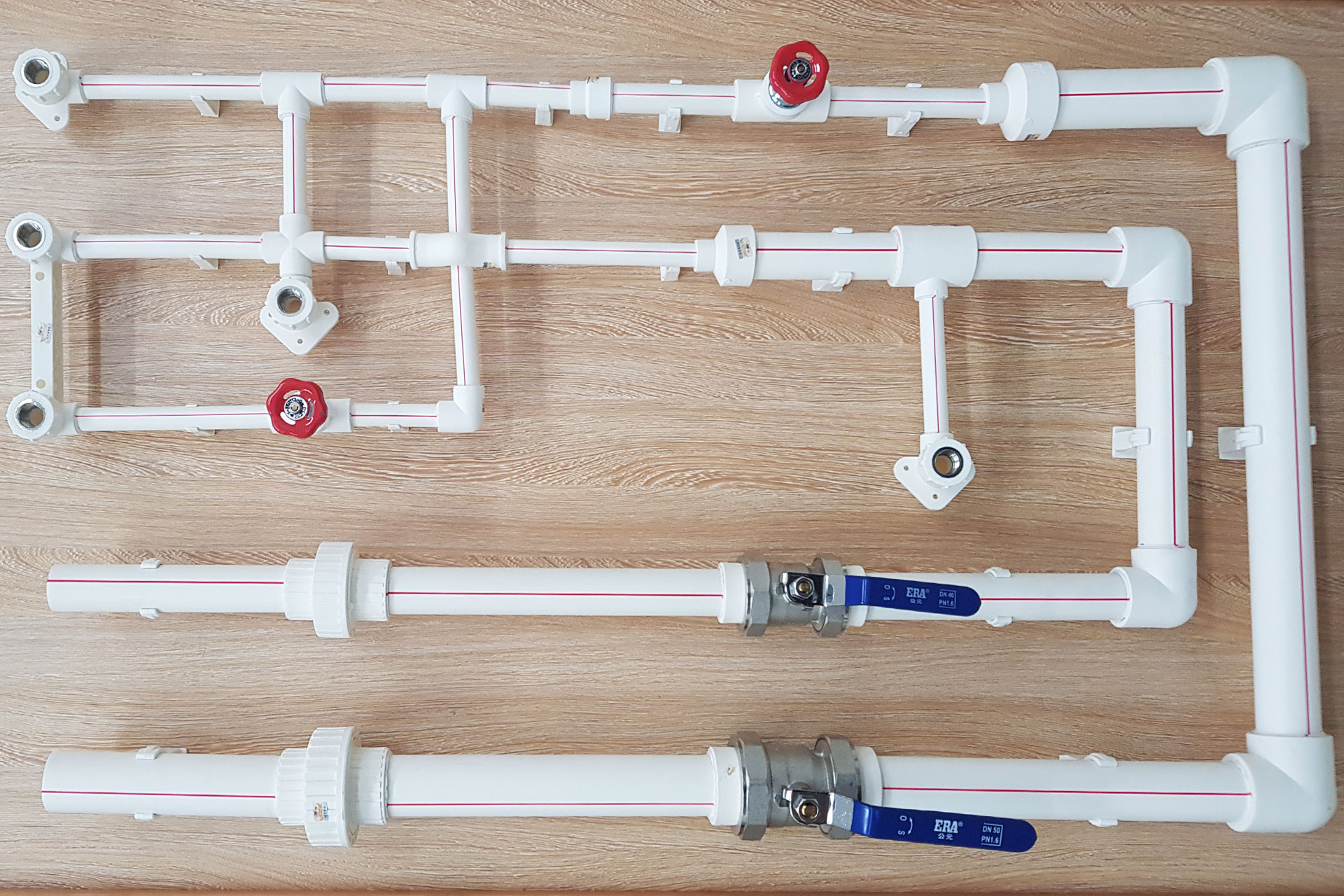

How To Install Ppr Pipes And Fittings Lifepluspipes Mark the welding depth on the ppr pipe wall with a marker; 5. at the same time, insert the pipes and fittings of ppr into the welding device and heat them according to the specified time; 6. after heating, push the pipe and pipe vertically and hold it for more than 5 seconds. don't use too much force in case it bends. Fusion is the process of joining ppr pipes and fittings to create a strong, leak proof connection: heat the pipe and fitting: use a fusion machine to heat the ends of the pipe and fitting. the temperature should typically be around 260°c (500°f), but always follow the manufacturer’s guidelines for specific temperatures and heating times. Heat welding machine. step 4: using your machine, heat up the ends of each pipe that will be joined until you can bend it by hand. step 5: before the material hardens, stuff the ends of both pipes into it at an angle. verify that the pipes and fitting are completely bonded with no space. step 6: keep the pipes steady as long as it takes for. Flange jointthe flange connection is the most important mechanical joint. it is used to joint pipes. or components such as valves or fittings in a range between 6mm to 2000mm.the connection is normally assembled with two flange ada. ters which are joined to the pipes, two backing rings and a flange gasket. the bolts a.

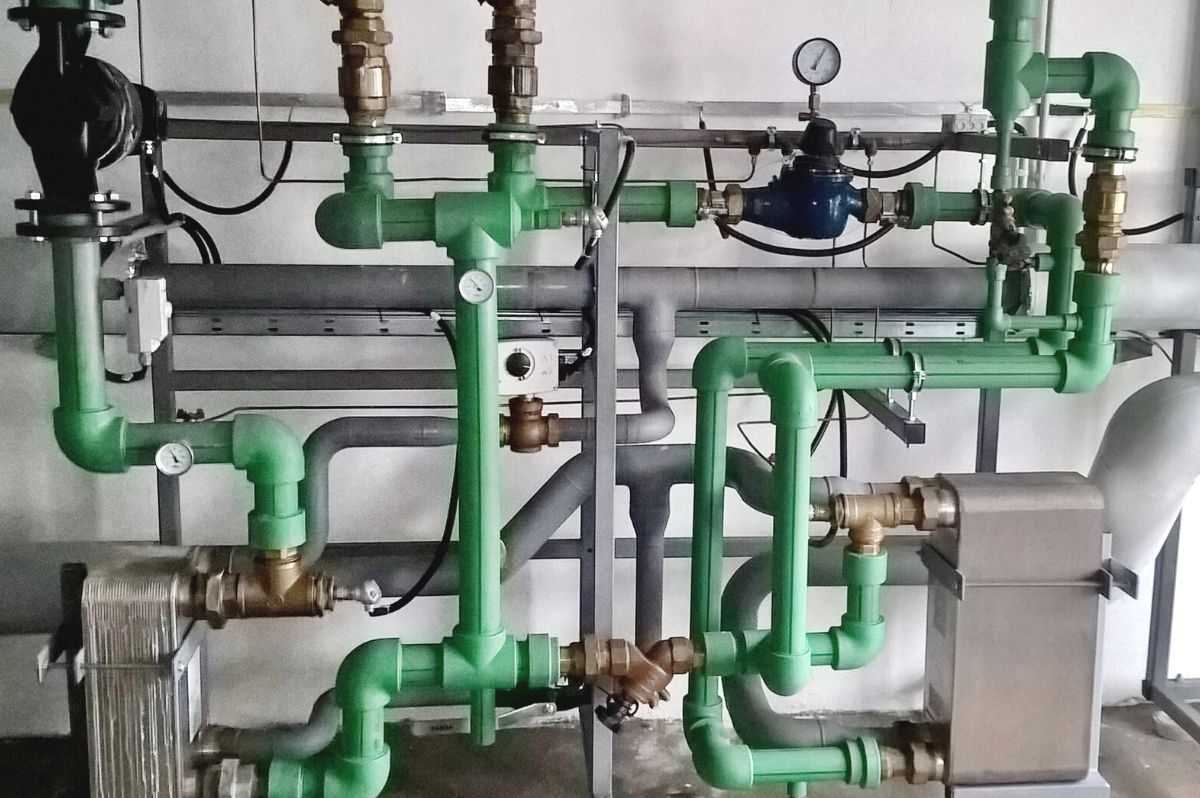

Ppr Pipe Philippines Supplier Manila Cebu Davao More Heat welding machine. step 4: using your machine, heat up the ends of each pipe that will be joined until you can bend it by hand. step 5: before the material hardens, stuff the ends of both pipes into it at an angle. verify that the pipes and fitting are completely bonded with no space. step 6: keep the pipes steady as long as it takes for. Flange jointthe flange connection is the most important mechanical joint. it is used to joint pipes. or components such as valves or fittings in a range between 6mm to 2000mm.the connection is normally assembled with two flange ada. ters which are joined to the pipes, two backing rings and a flange gasket. the bolts a.

How To Install The Ppr Pipe And Fittings

Era Ppr Piping System Parklane Commercial Corporation

Comments are closed.