How To Identify O Ring Boss Hydraulic Fittings

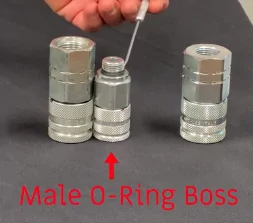

How To Identify O Ring Boss Hydraulic Fittings Youtube An example of how to identify the fitting and order a new adaptor on our website would be: if you have a male sae o ring boss adaptor, measure the outside diameter across the threads, for example if the fitting measures 12.7mm or 1 2” then we would call this a 1 2” sae o ring boss. its imperial measurement is the fitting size. Welcome back to heads up for hosers by gregg distributors, where we will teach you everything there is to know about fittings. in this episode, we dive deep.

How To Identify Npt Thread And Other Hydraulic Fitting Types Rubber How to identify o ring boss hydraulic fittings. The sae orb male o ring boss thread and the straight jic 37° flare are both the same threads, although the orb seals with an o ring for a better leak free connection. bspp thread – british standard parallel – a straight thread often expressed as a “g” thread that requires a secondary bonded washer or dowty seal to make a leak free. Orb threads are a popular type of fitting used in hydraulic systems. they have a male thread with an o ring seated in a groove on the female port. this design creates a reliable seal that prevents leakage even under high pressure. now, let’s explore the significance of o rings within these fittings. the importance of o rings in hydraulic systems. This thread is frequently used in hydraulic systems. the male connector has a straight metric thread and a 60° (included angle) recessed cone. the female has a straight thread and a tapered nose globeseal seat. the seal takes place between the cone of the male and nose of the tapered nose globeseal fl areless swivel.

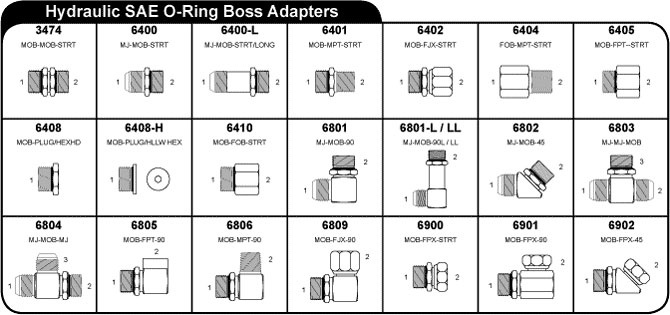

O Ring Boss Fitting Size Chart Orb threads are a popular type of fitting used in hydraulic systems. they have a male thread with an o ring seated in a groove on the female port. this design creates a reliable seal that prevents leakage even under high pressure. now, let’s explore the significance of o rings within these fittings. the importance of o rings in hydraulic systems. This thread is frequently used in hydraulic systems. the male connector has a straight metric thread and a 60° (included angle) recessed cone. the female has a straight thread and a tapered nose globeseal seat. the seal takes place between the cone of the male and nose of the tapered nose globeseal fl areless swivel. The seal is made where the o ring is compressed between the flanged head and the flat surface of the port. the connection is held by threaded bolts. iso 6149 port and stud ends with iso 261 threads and o ring seal though it is similar to the sae j514 straight thread o ring boss (orb), this type of connection incorporates metric threads. the. Recommended sae o ring non adjustable stud assembly instructions. step 1: inspect all components for damage or contami nation. step 2: lubricate o ring and threads on tting with your hydraulic sytems uid. step 3: turn tting into port until nger tight, then torque to the value shown in the following table.

Hydraulic Fittings Size Chart Qc Hydraulics The seal is made where the o ring is compressed between the flanged head and the flat surface of the port. the connection is held by threaded bolts. iso 6149 port and stud ends with iso 261 threads and o ring seal though it is similar to the sae j514 straight thread o ring boss (orb), this type of connection incorporates metric threads. the. Recommended sae o ring non adjustable stud assembly instructions. step 1: inspect all components for damage or contami nation. step 2: lubricate o ring and threads on tting with your hydraulic sytems uid. step 3: turn tting into port until nger tight, then torque to the value shown in the following table.

Hydraulic Fitting Identification Qc Hydraulics

Comments are closed.