How Strong Is Pet Bottle Filament

How Strong Is Pet Bottle Filament Cnc Kitchen Pull trusion simplifies this process quite a bit because you just pull a piece of pet tape through a cheap 3d printer nozzle and get filament out of it. an average pet bottle has around 20g of usable material, so it’s not a ton of filament that you’re getting. the interesting part here is that the nozzle is only heated to around 200°c. I recently got some samples of 3d printing filament made from old pet bottles. before i decide whether to build my own machine, i wanted to take a look at th.

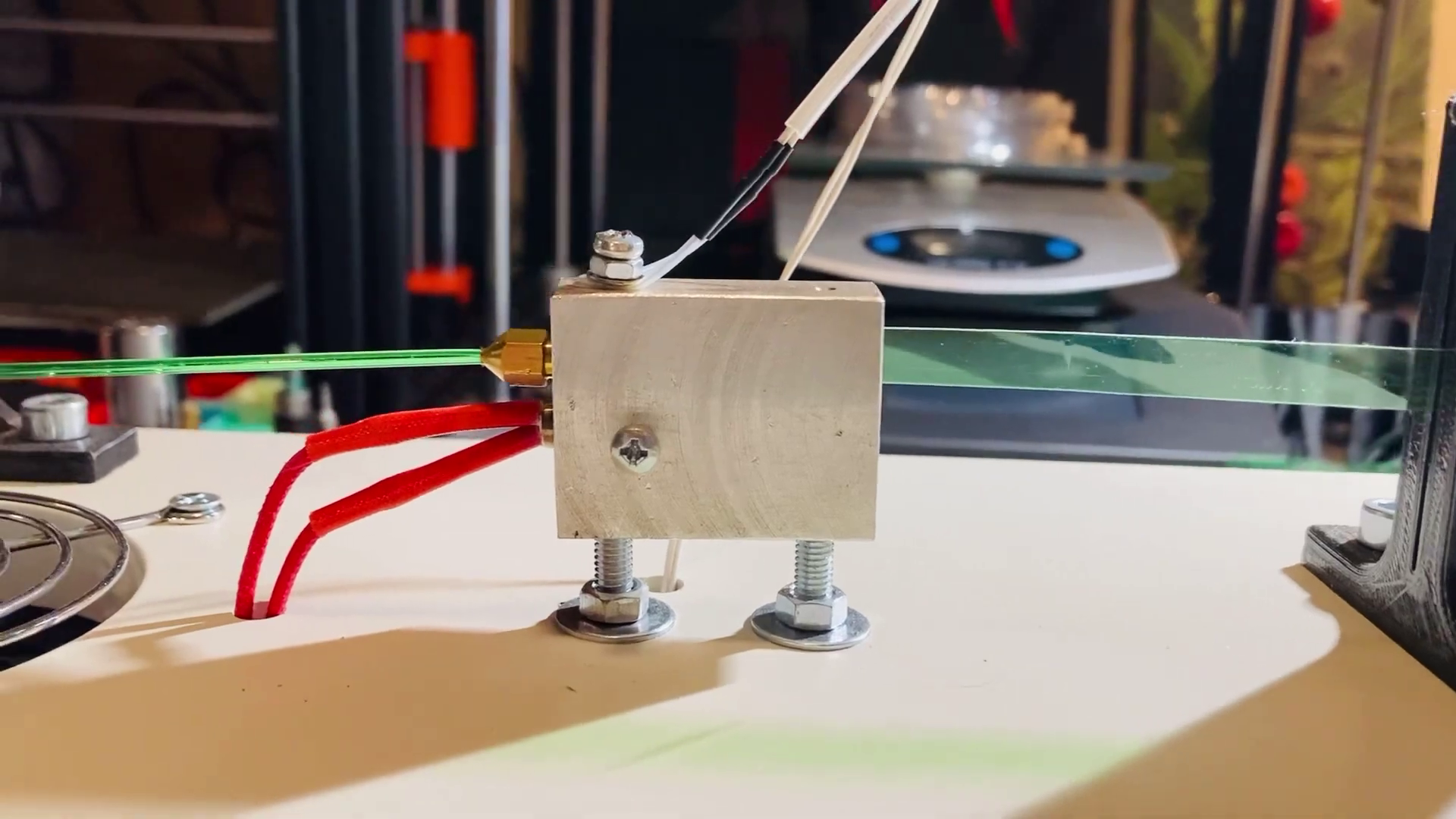

How Strong Is Pet Bottle Filament Cnc Kitchen Most 3d printers use either 1.75mm or 2.85mm filament. make sure the filament you choose matches the diameter supported by your printer. printing temperature: pet filament requires higher printing temperatures compared to other materials. check the recommended temperature range provided by the filament manufacturer. Step 3: assembling the hot end. the nozzle is a standard 0.4mm nozzle, so we need to first drill that out to the filament diameter. we're aiming for 1.75mm but the filament expands a little after it leaves the hotend, so we'll drill it out using a 1 16" drill bit, which is just under 1.6mm. Collect and clean the bottles. wash the bottles multiple times, remove labels and any sticky residue as much as possible. if the bottles aren’t completely straight (most bottles have embossings), the filament will be uneven in the end. use a stove to straighten them. fill a bottle with a bottle cap of water (around 5 milliliters) and close it up. The advantages of 3d printing with pet filaments are: it is strong and affordable. the combination of its chemical resistance, thermal resilience, and mechanical strength makes pet filament a good fit for food packaging and bottled drinks. pet is completely recyclable and is often recycled in large quantities.

How Strong Is Pet Bottle Filament Cnc Kitchen Collect and clean the bottles. wash the bottles multiple times, remove labels and any sticky residue as much as possible. if the bottles aren’t completely straight (most bottles have embossings), the filament will be uneven in the end. use a stove to straighten them. fill a bottle with a bottle cap of water (around 5 milliliters) and close it up. The advantages of 3d printing with pet filaments are: it is strong and affordable. the combination of its chemical resistance, thermal resilience, and mechanical strength makes pet filament a good fit for food packaging and bottled drinks. pet is completely recyclable and is often recycled in large quantities. Polyethylene terephthalate (pet) is a familiar material. it is generally found in plastic water bottles and other types of plastic packaging. it is also used in the manufacture of everyday items, but in its standard form, it is hard to turn into filament. this is where petg steps in, the difference being the glycol added to the formula. Step 5: bottle prep. first, you need to drill undersize holes in the caps of your bottles and insert a schrader valve, then silicone seal it. make sure the valve is held tight mechanically before adding silicone caulk, which is not an adhesive and will not secure the valve under pressure.

How Strong Is Pet Bottle Filament Youtube Polyethylene terephthalate (pet) is a familiar material. it is generally found in plastic water bottles and other types of plastic packaging. it is also used in the manufacture of everyday items, but in its standard form, it is hard to turn into filament. this is where petg steps in, the difference being the glycol added to the formula. Step 5: bottle prep. first, you need to drill undersize holes in the caps of your bottles and insert a schrader valve, then silicone seal it. make sure the valve is held tight mechanically before adding silicone caulk, which is not an adhesive and will not secure the valve under pressure.

How Strong Is Pet Bottle Filament Cnc Kitchen

Comments are closed.